...

heavy duty sewing machine industrial 【heavy duty sewing machine industrial】

Read MoreGetting Started

heavy duty sewing machine industrial

...

heavy duty sewing machine industrial 【heavy duty sewing machine industrial】

Read MoreFor both hobbyists and professional tailors, the Zig Zag Dressmaker Sewing Machine promises practicality. Its ability to transition between different stitch types seamlessly means that an entire project can be completed with just one machine, rather than having to switch between multiple devices.

heavy duty sewing machine industrial

...

heavy duty sewing machine industrial 【heavy duty sewing machine industrial】

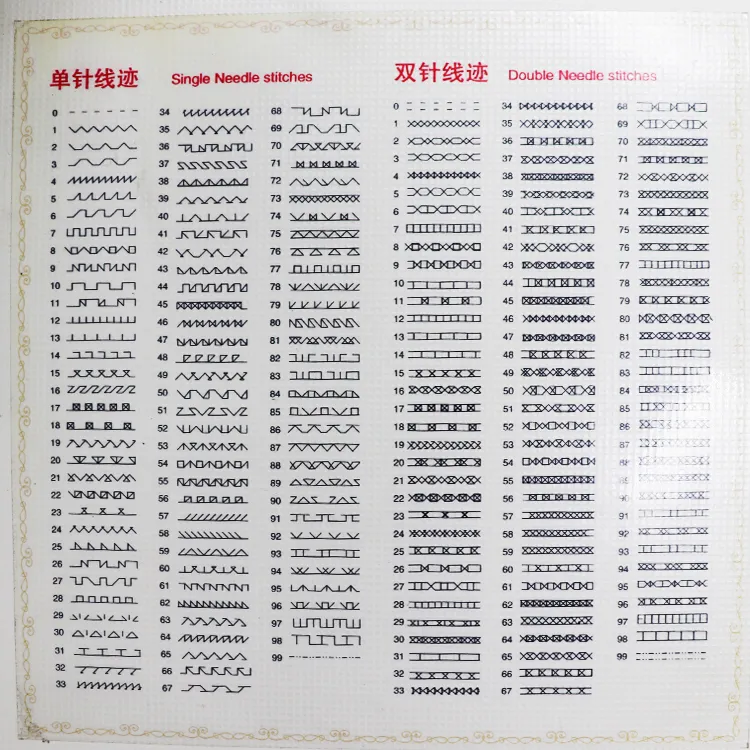

Read MoreIn conclusion, twin needle sewing is a valuable technique that serves multiple purposes in the sewing world. From creating stretchy hems in knit fabrics to adding decorative details and enhancing the durability of seams, this method is an essential tool for anyone looking to refine their sewing skills. Whether you're a beginner or an experienced sewist, mastering twin needle sewing can open new doors for creativity and precision in your sewing projects. By utilizing this technique, you can achieve professional-looking results that showcase your craftsmanship and elevate your handmade creations.

heavy duty sewing machine industrial

...

heavy duty sewing machine industrial 【heavy duty sewing machine industrial】

Read MoreOne of the key advantages of stitch machine embroidery designs is their versatility. These designs can be used to embellish a wide range of items, from clothing and accessories to home décor and gifts. Whether you're looking to personalize a pair of jeans with a unique design or add a touch of elegance to a table runner, stitch machine embroidery designs can bring your vision to life with ease.

heavy duty sewing machine industrial

...

heavy duty sewing machine industrial 【heavy duty sewing machine industrial】

Read More

It has been discovered that heavy-duty

It has been discovered that heavy-duty