long arm zig zag sewing machine

Latest articles

long arm zig zag sewing machine4. Budget Heavy-duty machines can vary significantly in price. Set a budget but consider the long-term value of investing in a quality machine that meets your needs rather than opting for a cheaper model that may not fulfill your requirements.

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineAn overlocker can also be used to gather fabric efficiently. By adjusting the tension settings and using a specific stitch technique, you can create beautiful gathers for skirts, blouses, and other design elements. This adds dimension and texture to your garments, enhancing their overall aesthetic appeal.

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read Morelong arm zig zag sewing machine

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineA double needle sewing machine, as the name suggests, uses two needles working in tandem to create symmetrical stitching. This capability is particularly beneficial for leather projects where strength and visual appeal are crucial. Whether you are crafting bags, jackets, or upholstery, this type of machine offers several advantages that can significantly enhance your leatherworking experience.

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineHeavy-duty sewing machines provide extra stitch strength, often with triple feed teeth. The maximum stitch length is longer, up to 8mm versus 5mm, to allow bigger basting-type stitches in heavy fabrics. Extra strong stitches prevent seam rupture in heavyweight materials under stress.

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineHeavy duty basic sewing machines find their place in various applications. They are popular among quilters who require precision and strength in stitching multiple layers of fabric. Fashion designers also benefit from the capabilities of these machines when working with denim and other tough textiles. Moreover, hobbyists and DIY enthusiasts can bring their creative visions to life with the reliability of a heavy duty machine, making everything from custom clothing to durable bags and accessories.

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineThe Mechanism Behind the Union Lockstitch Sewing Machine

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineIn the realm of textile manufacturing, the evolution of equipment has played a crucial role in enhancing productivity, precision, and versatility. Among the myriad of sewing machines designed for various applications, the double stitch machine stands out as a pivotal advancement. With its unique capabilities, it has transformed how garments and textiles are produced, offering numerous benefits to manufacturers and consumers alike.

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineConclusion

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

long arm zig zag sewing machineIn summary, the lockstitch sewing machine is a cornerstone of the textile industry, combining strength, versatility, and precision to meet the demands of modern manufacturing. As fashion trends evolve and production techniques become more sophisticated, the role of the lockstitch machine remains significant. Its ability to produce durable and high-quality seams makes it essential not only for large-scale garment production but also for small businesses and home sewists alike. As the industry continues to innovate, the lockstitch sewing machine will undoubtedly adapt, maintaining its importance in the art of sewing and textile creation.

...

long arm zig zag sewing machine 【long arm zig zag sewing machine】

Read More

Popular articles

The long arm double needle chain stitch is used across various sectors of the textile industry

. In apparel manufacturing, it is commonly employed for sewing seams on items that require flexibility, such as sportswear, jeans, and active garments. The stitch proves vital in providing a flat seam appearance while maintaining structural integrity, thus ensuring that the garments can withstand regular wear and tear.long arm double needle chain stitch

Automatic machine sewing refers to the use of advanced sewing machines that operate with minimal human intervention. These machines are equipped with sophisticated features such as programmable settings, multi-needle capabilities, and automatic threading systems. This automation allows for consistent and high-quality stitching, reducing the likelihood of human error and ensuring uniformity in mass production.

Conclusion

Latest articles

-

1. Select a Stitch Most sewing machines will allow you to select either a straight stitch or a zigzag stitch when using a twin needle. A straight stitch is often used for hems, while a zigzag can add decorative flair. Avoid stitches that may cause overlapping, as this can lead to jams.

-

Additionally, the use of these machines often aligns with sustainable practices. Many leatherworkers value the craftsmanship and durability that hand-sewn items provide, resulting in products that are not only beautiful but also long-lasting. They can also repair and upcycle existing leather goods, promoting a circular economy within the fashion and accessories sectors.

-

-

When it comes to selecting a heavy-duty sewing machine, several brands are renowned for their quality and reliability. Brands like Singer, Brother, and Janome have established their names in the sewing industry. For instance, the Singer Heavy Duty 4423 is a popular choice known for its sturdy construction and versatility. Alternatively, the Brother ST371HD offers a wide array of features suitable for heavy materials while maintaining user-friendliness.

-

While mastering the coverstitch chain stitch may seem daunting at first, many sewing enthusiasts find the process rewarding. Dedicated coverstitch machines, or serger/coverstitch combo machines, have made it easier than ever to create professional-quality finishes at home. There are plenty of tutorials available online, ranging from beginner lessons to advanced techniques, helping sewists develop their skills.

Links

- 5. Winding The slit tapes are wound onto rolls for storage and transportation.

- When it comes to safety in the workplace, there are few measures more effective than the use of floor marking tape. This versatile material is not only highly visible but also incredibly durable, making it an essential tool for keeping workers safe and preventing accidents in any industrial or commercial setting.

- ,。、,,。,,,。,,。

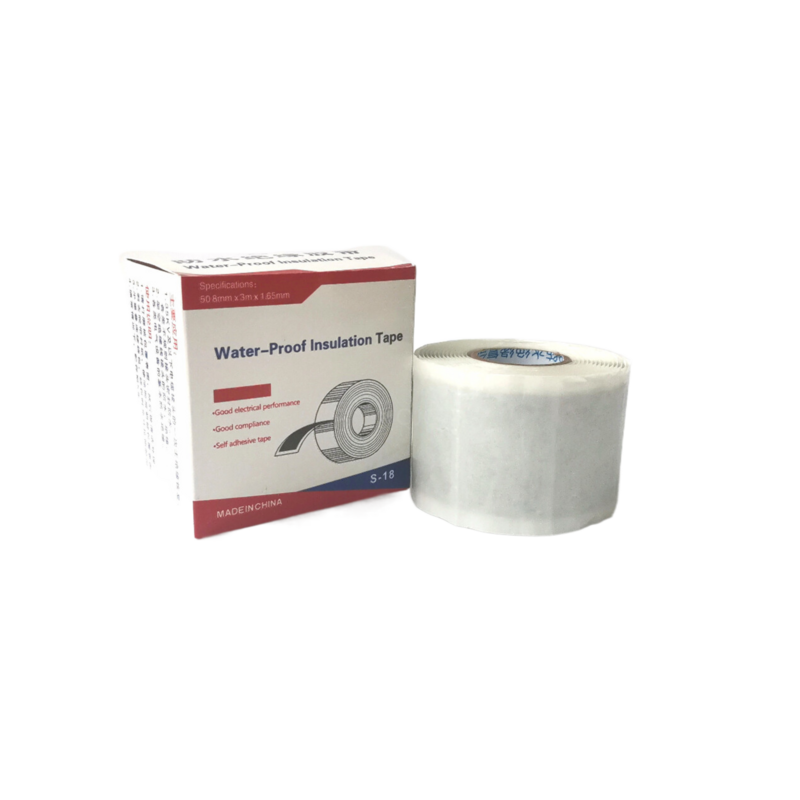

- In the realm of electrical engineering and construction, the integrity of cable insulation is paramount. One critical aspect of maintaining this integrity is preventing water intrusion, which can lead to electrical shorts, equipment failure, and even safety hazards. To address this challenge, semi-conductive water blocking tape has emerged as a reliable and effective solution.

Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements

Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements Its long-lasting formula ensures that your seals will remain intact for years to come, providing reliable protection against the elements butyl rope caulk. Whether you're dealing with a leaky roof, a drafty window, or a,butyl rope caulk is the solution you need.

butyl rope caulk. Whether you're dealing with a leaky roof, a drafty window, or a,butyl rope caulk is the solution you need.

rubber seal strip. In addition, rubber seal strips can also help to reduce drafts and improve indoor air quality by preventing the entry of outdoor pollutants.

3. Regulatory Compliance Many industries are subject to safety regulations that require proper signage and markings. Utilizing red and white floor marking tape can help businesses comply with these regulations, thereby avoiding potential fines or legal issues.

Since many hydraulic control panels are used on active (often outdoor) job sites, these control boxes often have to be built a little tougher than others. You might need an enclosure that’s weatherproof, corrosion-resistant, impact-resistant or all of the above. Sensor lights for troubleshooting are also especially useful in hydraulic control boxes, helping users to pinpoint a system error in these often-complex networks of valves, cylinders and hoses.

Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables

Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables automotive wire wrap tape.

automotive wire wrap tape.In summary, heat tape is a versatile and invaluable tool across multiple sectors. Its ability to provide precise, reliable heat makes it essential for preventing frost damage in pipes, crops, and buildings. As field technology advances, the efficiency and performance of heat tape continue to improve, cementing its role as a go-to solution for temperature management. Whether used in residential settings or industrial applications, understanding how to properly use and install heat tape can lead to significant benefits and peace of mind during cold weather conditions. With proper care and consideration, heat tape remains an investment in safety and efficiency.

Every component in a control box is selected for its ability to perform under specific conditions – from extreme temperatures to the threat of corrosion. It’s this thoughtful assembly that makes the control box not just a container, but a finely tuned instrument crucial for the smooth operation of electrical systems.