l 2 anodizing lines,max profile anodizing length 7.5 meters.

- Upgraded Aesthetics Modern rollers are designed to be visually appealing, seamlessly blending with contemporary architectural elements.

...

Sail making machine 【Sail making machine】

Read MoreSo if you are planning to start a bag-making business with a lot of leather sewing involved right now, get yourself one from that range. All else, I would go with the less overwhelming, easy-to-move, domestic HD models listed below.

...

Sail making machine 【Sail making machine】

Read More...

Sail making machine 【Sail making machine】

Read More3. Versatility Besides garment making, double needle sewing machines are also employed in home décor projects, quilting, and leatherwork. Their adaptability make them a valuable addition to any sewing setup.

...

Sail making machine 【Sail making machine】

Read MoreIn addition, hand sewing machines encourage creativity and innovation. Craftsmen have the freedom to experiment with various stitching techniques and decorative elements, resulting in unique and individualized pieces that reflect their personal style. This artistic expression is often lost in mass production, making hand-sewn upholstery a valuable and sought-after commodity.

...

Sail making machine 【Sail making machine】

Read MoreVersatility in Leatherwork

...

Sail making machine 【Sail making machine】

Read More...

Sail making machine 【Sail making machine】

Read MoreThe fundamental process of chain stitch sewing begins with a sewing machine capable of producing this specific stitch type. A chain stitch is formed when the needle threads the fabric while simultaneously creating a loop of thread that interlocks with the preceding stitch. The result is a series of chain-like stitches that are not only secure but also have a pleasant aesthetic finish. While a specialized chain stitch sewing machine can enhance efficiency and precision, traditional hand-sewing methods are also used, particularly in crafts and embroidery.

...

Sail making machine 【Sail making machine】

Read More...

Sail making machine 【Sail making machine】

Read MoreThe applications of zigzag sewing machines are endless. In garment construction, zigzag stitches are invaluable for finishing seams and hems. They can also be used for appliqué work, allowing sewists to attach fabric shapes onto a base fabric creatively. Additionally, for quilting, the zigzag stitch can add intricate designs or secure layers together.

...

Sail making machine 【Sail making machine】

Read MoreHeavy-duty sewing machines are specifically designed to handle thick fabrics and multiple layers with ease. Unlike standard sewing machines, they feature robust constructions, stronger motors, and specialized needles, making them ideal for tasks that require extra strength. Whether you are working with denim, upholstery, or quilts, a heavy-duty machine provides the reliability needed to ensure a smooth sewing experience.

In the world of crafting and tailoring, the tools we choose can make all the difference. For leatherworkers, having a reliable and efficient sewing machine is paramount to achieving high-quality results. Among the various options available, the Cub Leather Sewing Machine stands out for its impressive capabilities tailored specifically for leather projects. This article explores the features, benefits, and applications of the Cub Leather Sewing Machine, making it an ideal choice for both amateur and professional leather crafters.

saddle stitch machine. The staples are neatly and securely fastened along the spine of the document, giving it a clean and polished appearance. This makes the document easier to handle and more attractive to readers.

saddle stitch machine. The staples are neatly and securely fastened along the spine of the document, giving it a clean and polished appearance. This makes the document easier to handle and more attractive to readers.The Importance of Long Upholstery Needles in Craftsmanship

1. Improved Stitch Quality The combination of an efficient feeding system and powerful motor results in high-quality stitches, even on the most difficult fabrics. This is particularly important for businesses that rely on professional-quality finishes for their products.

Several factors contribute to the pricing of fully automatic sewing machines. Brand reputation plays a significant role; well-established brands known for their quality and innovation tend to charge more for their products. Additionally, the complexity of features offered also impacts pricing. Machines with specialized functions, such as quilting capabilities or multi-needle systems for embroidery, will naturally be more expensive due to the technology involved.

In the ever-evolving world of packaging and sealing, efficiency and convenience are paramount. One of the most innovative tools to emerge in recent years is the handheld bag closer. Designed to streamline the sealing process, this versatile device has transformed various industries, from food production to textiles, offering businesses a reliable solution to ensure their products reach consumers intact and secure.

4. Additional Accessories Many companies provide optional accessories that can enhance the functionality of the bag closer machine. These accessories can include conveyors, different types of sealing heads, or additional training for operation. While they can improve performance, they also add to the initial cost.

Benefits of Heavy-Duty Machines

l 2 anodizing lines,max profile anodizing length 7.5 meters.

- Upgraded Aesthetics Modern rollers are designed to be visually appealing, seamlessly blending with contemporary architectural elements.

The most suitable and commonly used grades for windows and doors are 6000 series, which include the following;

While aluminum does have its merits, it just can’t compete with the grandeur and reliability that wrought iron brings to the table. It really only has an edge in the short term cost consideration and maintenance needs.

1% by weight, significantly enhances iron's properties1% by weight, significantly enhances iron's properties

1% by weight, significantly enhances iron's properties1% by weight, significantly enhances iron's properties steel or iron stronger. It increases the toughness, hardness, and resistance to wear and tear. As a result, steel is stronger than pure iron both in terms of tensile and yield strength.

steel or iron stronger. It increases the toughness, hardness, and resistance to wear and tear. As a result, steel is stronger than pure iron both in terms of tensile and yield strength. what is a window profile. Traditional homes often feature more ornate profiles, while modern designs tend towards sleek, minimalist frames. The choice of profile can also impact the amount of natural light entering a space, the view it affords, and even the level of soundproofing.

what is a window profile. Traditional homes often feature more ornate profiles, while modern designs tend towards sleek, minimalist frames. The choice of profile can also impact the amount of natural light entering a space, the view it affords, and even the level of soundproofing.Sliding windows are a popular choice for homes and buildings due to their ease of use and stylish design. However, over time, the rollers on these windows may wear out or become damaged, making it difficult to open and close the window smoothly. When this happens, it is important to replace the sliding window rollers to ensure that the window continues to function properly.

Cast iron ornaments are more than mere decorative accents; they are enduring symbols of craftsmanship and tradition. Crafted with precision and attention to detail, each piece showcases the mastery of skilled artisans, echoing the rich heritage of centuries past. Whether adorning a gate, fence, or interior space, these cast iron ornaments exude a sense of refinement that transcends fleeting trends.

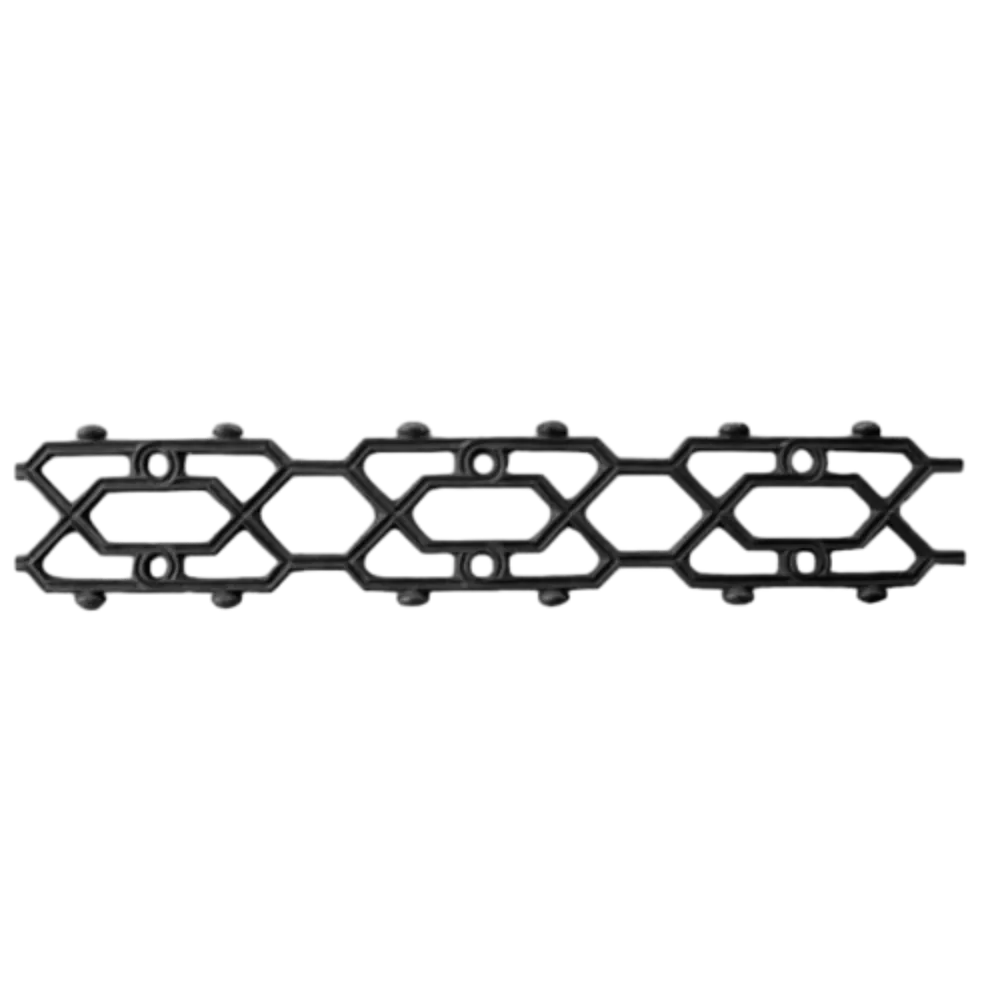

Sliding door wheels, often called rollers, are small, circular components that allow doors to glide effortlessly along a track. They are typically made from a variety of materials, including nylon, steel, or even rubber. Each material comes with its own set of advantages and disadvantages, affecting the door's performance, durability, and cost.

1. Nylon Wheels These are the most common type of wheels used for sliding doors. Nylon is lightweight, resistant to corrosion, and produces minimal noise during operation. Nylon wheels are ideal for interior doors, as they glide smoothly and require minimal maintenance. However, they may wear down faster than other materials when exposed to outdoor conditions.

Styles of Single Driveway Gates

Think of the cast iron frying pan you probably have in your kitchen. Unlike a stainless steel saute pan which likely has a handle made of a separate piece that had to be attached to the main body of the pan, your cast iron is all one continuous piece that was formed together in a mold.

For those with a creative knack, wrought iron can be shaped into intricate designs that reflect personal style and enhance the home’s decor.