leather walking foot

Latest articles

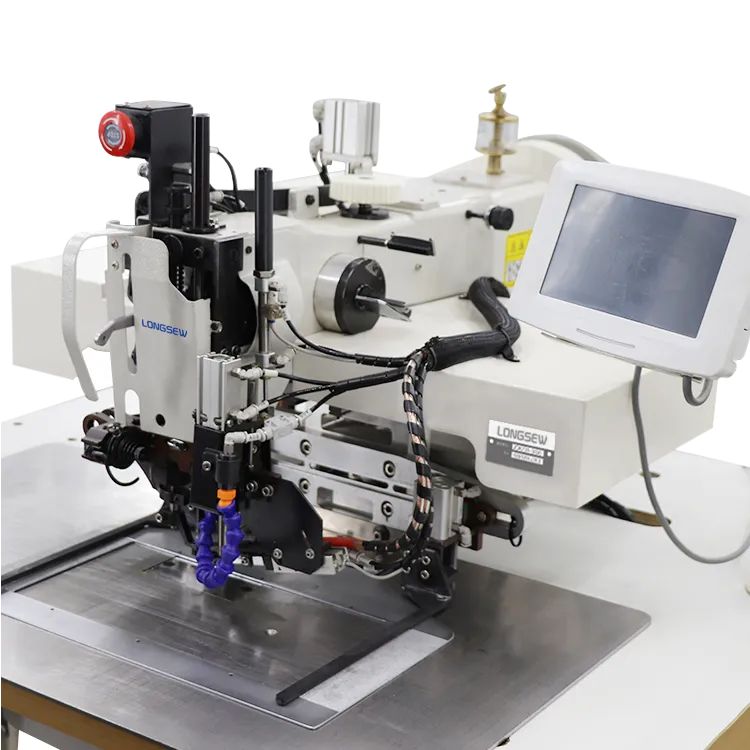

leather walking footOn the other hand, heavy-duty machines may have a steeper learning curve due to their advanced features and capabilities. However, this shouldn't deter beginners. Many heavy-duty models, offer helpful tutorials and guides to assist newcomers in mastering their machine's functions.

...

leather walking foot 【leather walking foot】

Read More

leather walking footAdditionally, the integration of modern technologies such as automation, sensors, and IoT (Internet of Things) features in bag closing machinery has revolutionized the packaging process. Automated systems can significantly reduce labor costs and improve efficiency, providing real-time monitoring and data collection for enhanced operational insights.

...

leather walking foot 【leather walking foot】

Read More

leather walking foot...

leather walking foot 【leather walking foot】

Read Moreleather walking foot

...

leather walking foot 【leather walking foot】

Read More

...

leather walking foot 【leather walking foot】

Read MoreWhen choosing a leather stitcher for sale, it is important to consider your specific needs and the type of projects you will be working on. Make sure to research the various options available and choose a machine that best suits your requirements. It is also a good idea to read reviews and testimonials from other customers to get an idea of the quality and performance of the machine.

leather walking foot...

leather walking foot 【leather walking foot】

Read More Advantages of Compound Feed Sewing Machines

compound feed sewing machine

leather walking foot

...

leather walking foot 【leather walking foot】

Read More...

leather walking foot 【leather walking foot】

Read MoreWhen selecting a walking foot, there are several factors to consider. First, ensure that the walking foot is compatible with your sewing machine model. Many manufacturers create specific walking feet designed to fit various sewing machines, so checking compatibility is crucial.

leather walking foot

...

leather walking foot 【leather walking foot】

Read MorePopular articles

Additionally, the machine’s design minimizes the likelihood of common sewing issues, such as thread breaking or tension irregularities. Many users report that the Cub Leather Sewing Machine provides consistent performance, allowing them to complete projects efficiently and to a high standard.

Chain Stitch Sewing An Overview of Technique and Applications

- In addition to its precision, single needle sewing is also known for its durability. The single needle creates strong and secure stitches that are less likely to come undone than those made with multiple needles. This makes single needle sewing ideal for sewing projects that require long-lasting and reliable stitching, such as clothing, bags, and home decor items.

What Does an Overlocker Do?

In the realm of industrial packaging, Flexible Intermediate Bulk Containers (FIBCs), commonly known as big bags, are essential for transporting bulk materials. The manufacturing of FIBCs involves various processes, among which sewing is critical to ensure the strength and reliability of the bags. At the heart of this sewing process lies the FIBC sewing machine head, a complex component that significantly influences the quality of the final product.

The Evolution and Benefits of CNC Machine Sewing

Latest articles

-

The Importance of PP Woven Bag Stitching Machines in Modern Manufacturing

-

Another benefit of using saddle stitch machines is their durability. The staples used to bind the pages together are strong and long-lasting, ensuring that the document remains intact even with frequent handling. This is especially important for documents that are meant to be used or distributed over an extended period of time.

Finally, practice makes perfect when it comes to sewing leather. Take the time to experiment with different stitch lengths and tensions to see what works best for your project. Test your machine on scrap pieces of leather before sewing your final project to ensure you're comfortable with the settings and techniques. With a bit of practice and patience, you'll soon be sewing beautiful and professional-looking leather items with your beginner leather sewing machine.

In terms of user experience, modern automatic button sewing machines are engineered to be user-friendly. Most models feature intuitive controls and detailed user guides, making them accessible even to those new to sewing. Many machines now include digital displays that provide step-by-step instructions and allow for easy adjustments to the settings. This ease of use encourages creativity, enabling users to experiment with different styles and techniques without fear of making mistakes.

2. Furniture Manufacturing: For stitching thick upholstery fabric or leather used on sofas, chairs, and other furniture, heavy duty machines greatly improve production efficiency and product quality.

- Automotive

- The Indispensable Role of Thick Rubber Gaskets in Industrial Applications

Single - for aerospace, aviation and carrier rockets, satellites, fighter jets, oil seals for new tanks, and pipelines

- One of the key advantages of a thin rubber gasket is its flexibility and ability to conform to irregular surfaces, making it an ideal choice for sealing joints and connections. Its thin profile allows for a tight seal without adding bulk or interfering with the overall design of the equipment. This ensures that the gasket can effectively prevent the leakage of fluids, gases, or debris, even in high-pressure or high-temperature environments.

- In conclusion, the 14x24x6 oil seal, despite its modest size, is a vital element in ensuring the reliable and efficient functioning of numerous industrial systems. Its precise dimensions, combined with the right material composition, make it a robust barrier against oil leaks and foreign particles. As a result, understanding and appreciating the significance of this component is essential for anyone involved in the maintenance and operation of industrial machinery.

- Secondly, OEM spark plugs contribute to improved fuel efficiency

Above, are all the components of an oil seal and all its naming conventions. Beyond selecting the correct size, the three primary selection criteria are Material, Lip, and Case. If you have an oil seal you’d like custom designed and made, send us your specifications through our Oil Seal Design Form.

In this blog, we attempt to highlight what are Oil Seals and the various Rotary Shaft Seals including Mechanical Face Seals, Water Pump Seals, Gland Packings, and V-Seals that are readily available.

testing spark plug wires. Loose connections can result in a weak spark or no spark at all, which can lead to engine misfires and decreased performance. Make sure that the wires are properly seated on the spark plugs and the ignition coil to prevent any issues with the electrical connection.

testing spark plug wires. Loose connections can result in a weak spark or no spark at all, which can lead to engine misfires and decreased performance. Make sure that the wires are properly seated on the spark plugs and the ignition coil to prevent any issues with the electrical connection.Rotary Wheel Of Auto Parts

What material are oil seals made from?

Fluoro natural rubber (FPM - FKM - Viton)

spring loaded

Crankshaft front seal

If you're looking for quality oil seals, bearings for industry or agriculture, ATV parts, and plenty more, check out The Big Bearing Store. With low prices and same day shipping in most cases, there's no reason to spend time searching the internet when everything you need is all in one place.