Sling sewing machine

Latest articles

Sling sewing machineModern industrial zig zag embroidery machines boast several features that set them apart from traditional machines

. Firstly, many models come with programmable controls, allowing operators to input specific designs and customize stitch types effortlessly. The incorporation of computer technology means that designs can be replicated with perfect accuracy, ensuring consistency across large production runs....

Sling sewing machine 【Sling sewing machine】

Read MoreOverall, overlock and coverstitch machines are indispensable tools for anyone involved in garment-making or sewing. These machines provide a fast, efficient, and professional way to finish edges and hems, ensuring that the final product is both durable and aesthetically pleasing. Whether you are a professional seamstress or a hobbyist sewer, investing in an overlock and coverstitch machine is sure to take your sewing projects to the next level.

Sling sewing machine...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machine...

Sling sewing machine 【Sling sewing machine】

Read More

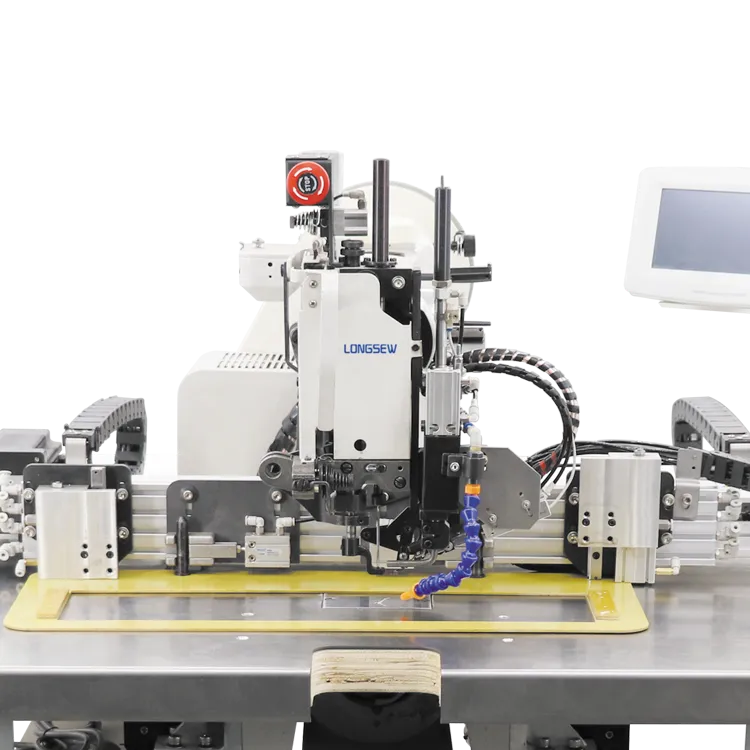

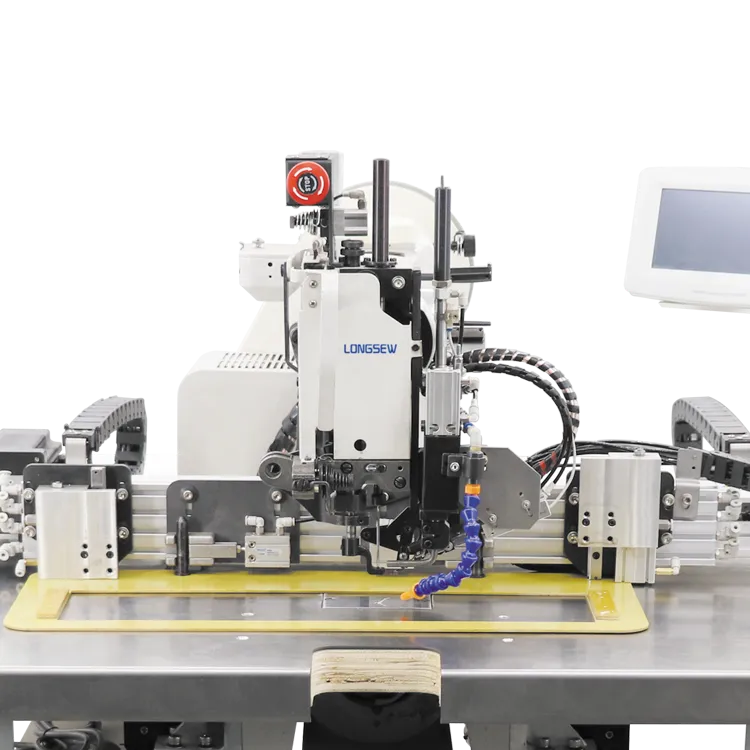

Sling sewing machineHeavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineIn conclusion, single needle sewing is more than just a technique—it's a celebration of craftsmanship, creativity, and sustainability. Whether used in the production of high-end fashion, DIY home projects, or quilting, this timeless method stands as a testament to the artistry inherent in sewing. As we navigate a rapidly changing world, embracing single needle sewing not only preserves traditional skills but also empowers individuals to express their creativity while promoting a more sustainable approach to fashion and textiles. In essence, it invites us all to slow down, appreciate the art of making, and treasure the beauty of handmade creations.

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineInvesting in a heavy-duty sewing machine for leather projects comes with various benefits

...

Sling sewing machine 【Sling sewing machine】

Read MoreDouble needle stitch is a popular technique in sewing and is widely used in a variety of applications such as quilting, garment construction, and hemming. This technique involves using two needles simultaneously to create parallel lines of stitching, resulting in a stronger and more durable seam.

Sling sewing machine...

Sling sewing machine 【Sling sewing machine】

Read More

...

Sling sewing machine 【Sling sewing machine】

Read MoreThe price of saddle stitch machines can vary significantly depending on several factors, including brand, model, features, and capabilities. Entry-level machines designed for small businesses or simple binding tasks might cost anywhere from $2,000 to $10,000. These machines generally have basic functionality and are suitable for low-volume production.

Sling sewing machine

...

Sling sewing machine 【Sling sewing machine】

Read MoreExecuting a chain lock stitch requires a deft hand and a keen eye. By looping the thread over and under the needle, then drawing the previous loop through, one creates a sequence of interconnected loops that form the chain. In hand embroidery, this process can be meditative, allowing the artisan to pour their creativity and patience into each stitch. With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged

With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged chain lock stitch.

chain lock stitch.

Sling sewing machine

...

Sling sewing machine 【Sling sewing machine】

Read MorePopular articles

In terms of functionality, the double needles chain stitch sewing machine is designed to handle a variety of materials. From lightweight fabrics like chiffon and silk to more robust materials such as denim and canvas, these machines can be easily adjusted to cater to different fabric weights and types. This versatility makes them a valuable asset in any sewing workshop, allowing businesses to take on a broader range of projects without needing multiple machines.

- In addition to their durability, heavy duty sewing machines from China also offer a range of features that make sewing easier and more efficient. Many models come with adjustable stitch length and width settings, automatic needle threading, and a variety of built-in stitches to choose from. These features help you customize your sewing projects and achieve professional-looking results.

The Technological Advancements

WHEN DO YOU NEED AN HD SEWING MACHINE?

2. Improved Accuracy Precision is critical in garment manufacturing. Auto cutter sewing machines utilize computer-controlled cutting technology that minimizes human error. This ensures that fabric pieces are cut exactly according to specifications, leading to better fit and finish in the final garments. The consistent accuracy of cuts also reduces fabric waste, significantly benefiting the environment and reducing costs.

The best sewing machine for upholstery should be able to sew thicker materials and reach angles that the usual sewing machines wouldn't be able to. With their efficiency, power, and performance your furniture will look amazing again in no time! Some features that you might want to look into are the built-in sewing speed reducer, the reverse feed system, and the adjustable feet lift.

Latest articles

-

In the world of crafting and garment making, sewing machines are invaluable tools that can transform ideas into tangible creations. Whether you’re a seasoned professional or a passionate hobbyist, finding the right sewing machine can significantly influence your projects’ outcome. One of the best ways to find exceptional sewing machines at affordable prices is by taking advantage of sewing machine specials.

-

Beyond garments, the double needle stretch stitch can also be employed in crafting projects and upholstery, such as making stretchable pillow covers or creating décor items requiring flexible seams. Its versatility makes it an essential technique for anyone looking to expand their sewing skills.

-

One of the main advantages of arm sewing machines is their compact size and lightweight design, which makes them easy to move around and transport. This makes them ideal for those who need to sew on the go or have limited space in their sewing area. Arm sewing machines are also great for sewing intricate designs or small projects, as they offer better visibility and control compared to traditional sewing machines.

-

Another notable benefit is the versatility that a walking foot provides. While it's especially known for its effectiveness with multiple layers and bulkier fabrics, this foot can also be advantageous for sewing straight lines and curves. Many modern sewing machines come with stitch settings compatible with the walking foot, allowing users to explore various sewing techniques. For example, one can easily create beautiful diagonal lines in quilting or sew intricate patterns that require precision.

-

4. Cost-Effective in the Long Run While the initial investment may be higher than a standard machine, the efficiency and durability of heavy-duty upholstery sewing machines can lead to cost savings over time. Frequent repairs on lesser machines can add up, making a high-quality machine a wise investment.

-

Another factor to consider in pricing is the timing of your purchase. Sewing machines are often discounted during promotional events such as Black Friday, Cyber Monday, or spring sales. Retailers may also offer discounts on previous year’s models to make way for newer inventory. Shoppers looking for a bargain can significantly benefit from keeping an eye on seasonal sales and clearance events, allowing them to purchase a higher-quality machine for a lower price.

5. Finishing Touches Once confirmed that the installation is leak-free, finish the area by covering it with appropriate flooring materials, ensuring that the floor waste is accessible for maintenance.

As manhole manufacturers, we often get asked about the purpose of manholes and the uses of manholes. And the answer is, that there are many functions of manholes when it comes to sewer or stormwater systems. The four main purposes of a manhole are:

As the world shifts towards more sustainable practices, stainless steel garbage bins align with eco-conscious initiatives. Stainless steel is 100% recyclable, meaning that when a bin eventually reaches the end of its life cycle, it can be melted down and repurposed without any loss in quality. This attribute significantly decreases the environmental impact associated with disposal. Moreover, opting for stainless steel bins reduces reliance on plastic, helping to mitigate the ongoing crisis of plastic pollution in landfills and oceans.

composite manhole covers

- Slotted Grates These covers feature slots or bars that allow water to drain while preventing larger debris from entering the drainage system. They are commonly used in residential driveways, parking lots, and sidewalks.

Applications of Gate Valves with Integral Bypass

Heavy-duty bike racks play a crucial role in promoting cycling within communities and urban environments. By providing reliable and secure options for bike parking, municipalities can encourage more people to consider cycling as a viable mode of transportation. Increasing the number of cyclists on the streets not only reduces traffic congestion but also lowers carbon emissions, contributing to a more sustainable future.

The Versatility and Convenience of Trunk Bike Carriers

Another significant aspect of monitoring manhole covers involves environmental protection. Many underground systems are designed to manage wastewater, stormwater runoff, and other pollutants. A compromised manhole cover can lead to contamination events where untreated sewage or stormwater enters natural waterways. Such incidents can have dire consequences for local ecosystems, wildlife, and public health. Regular monitoring and maintenance ensure that these covers remain intact and functional, thus playing a critical role in safeguarding our environment.

Gully drain covers come in various types, each designed for specific applications and environments. The most common materials used include cast iron, stainless steel, and plastic. Cast iron covers are known for their durability and strength, making them ideal for heavy traffic areas such as roads and industrial zones. Stainless steel is corrosion-resistant and often used in coastal areas where saltwater exposure can degrade other materials. Plastic covers are lightweight and easy to install, often used in residential areas or less trafficked spaces.

gully drain cover

As previously discussed manholes vary in depth based on their function. Most manholes are categorized as shallow normal or deep. Shallow manholes are typically only two to three feet deep, while deep manholes are any manhole greater than 150 cm deep. Due to this variation, there is no one-size-fits-all answer to the question “How deep is a manhole?”

Gate valve wheels are made from a variety of materials, including brass, stainless steel, and cast iron, depending on the application and environmental conditions. The choice of material affects the durability, corrosion resistance, and overall performance of the wheel. For instance, stainless steel wheels are often used in corrosive environments due to their resistance to rust and degradation.

gate valve wheel

Understanding Drain Cover Hooks

Additionally, the materials used should be carefully selected to resist corrosion and wear from environmental factors, ensuring longevity despite constant exposure to the elements. The installation process should also consider how these structures interact with other urban infrastructure, such as sidewalks, drainage systems, and utilities, to avoid disruption and maintain safety for pedestrians.

1. Assess the Area Evaluate the topography of the driveway to determine the best location for the drain channel. It should be positioned where water naturally flows.

The Benefits of Removable Bollards in Sydney

Facilitating Water Management

There are various types of drainage gully systems available to cater to different landscape designs and needs. Traditional concrete gullies are robust and can handle substantial water flow, making them suitable for high-traffic areas. On the other hand, plastic or polymer options are lightweight, easier to install, and can be a cost-effective solution for residential patios.

Environmental Protection

5. Heavy-Duty Saddle Clamps Constructed for demanding environments, these clamps are designed to bear heavy loads and withstand extreme conditions.

Benefits of Using Gate Valves

Enhanced Security

Exploring Square Gratings A Comprehensive Overview

The Art of Street Furniture Merging Function and Aesthetics

Where can i buy a manhole cover? is a very common question people would think ahead without thinking what to consider first facing the fact that you will just be confused with the array of choices available in the market if you are not well equipped with knowledge prior to buying.

Applications of Gate Valves in Korea

The environmental benefits of gully covers extend beyond erosion control. By managing water runoff effectively, these structures can play a vital role in flood prevention. During heavy rainfall events, large gully covers help to slow down and absorb excess water, reducing the risk of downstream flooding. This aspect is particularly crucial in regions prone to extreme weather patterns and climate change impacts. The strategic placement of gully covers can be part of a larger hydrological management strategy that includes the restoration of natural drainage systems and the enhancement of riparian buffers.

Conclusion

In the vast landscape of urban infrastructure, several elements go unnoticed yet play a pivotal role in maintaining the delicate balance of city life. Among these, indoor manhole covers serve as a critical component, often overlooked but essential for various reasons. These seemingly mundane structures have a significant impact on safety, accessibility, and efficiency within buildings, particularly in commercial settings.

From older cast iron covers with intricate patterns to modern, lighter-weight materials like composite polymers, each cover tells a unique story of urban development.

Gratings, often found at the intersections of streets and drain channels, serve as covers for stormwater inlets. These metal or plastic structures provide several critical functions. First and foremost, they allow water to flow into the drainage system while preventing debris, such as leaves, trash, and larger objects, from entering the pipes below. This debris can clog the system, leading to backups and flooding.

drain channel & grating

Installation

Understanding Gate Valves

Vertical grating drains are typically composed of durable materials such as stainless steel or high-density polyethylene, ensuring longevity and resistance to corrosion and environmental stresses. The design usually features a vertical orientation that allows water to flow directly into the drain while simultaneously filtering debris through the grate. This vertical structure enables the effective management of surface runoff, especially during heavy rainfall.

Bollards are short, sturdy posts that are used to control vehicle access to pedestrian areas, often placed strategically to reinforce safety. The implementation of black bollards in urban environments reflects a thoughtful balance between functionality and style. The color black not only adds a sleek, modern touch to the urban palette, but it also tends to complement various architectural styles and surroundings. This versatility makes black bollards a popular choice among city planners and designers.

(vi) Grout or Mortar: Grout or mortar fills gaps between precast concrete sections or bricks in manhole construction. It helps to provide stability, prevent water infiltration, and ensure a tight seal between different components.

Saddle clamps, often made from robust metal, are essential components in various industries for securing pipes, cables, and other cylindrical objects. Their design and functionality make them highly effective in maintaining organization and preventing damage due to movement or environmental factors. In this article, we will delve into the various aspects of saddle clamp metal, including its functions, applications, and the advantages it offers.

The primary function of these clamps is to create a tight seal around the damaged area of the pipe. By compressing the rubber gasket or sealing element against the pipe surface, the clamp effectively isolates the leak, thus preventing further fluid loss. This method of repair is often preferred because it is quick, requires minimal downtime, and can be performed without the need for extensive piping modifications or full replacements.