Sling sewing machine

Latest articles

Sling sewing machineBenefits of Using a Chain Stitch Sewing Machine

...

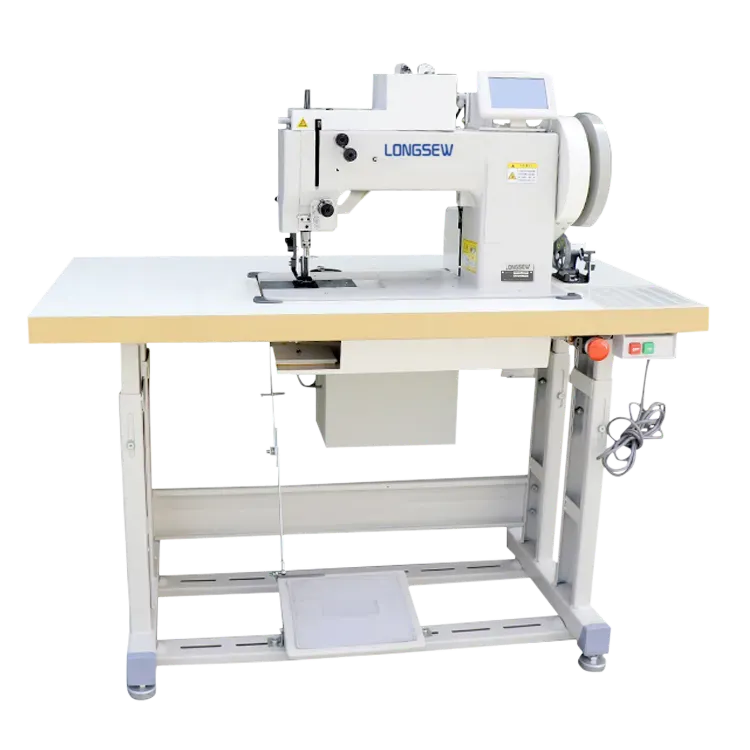

Sling sewing machine 【Sling sewing machine】

Read MoreIn China, heavy duty sewing machines are used in a variety of industries, including clothing manufacturing, upholstery, and automotive upholstery. These machines are capable of stitching through multiple layers of thick fabric, leather, and even denim, making them ideal for heavy-duty projects.

Sling sewing machine...

Sling sewing machine 【Sling sewing machine】

Read MoreSling sewing machine

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machine3. Versatility Chrome needles come in various sizes and types, making them suitable for different sewing techniques and fabric types. From light-weight fabrics to heavy-duty materials, there is a chrome needle designed for every sewing need.

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineA sewing machine is a versatile and indispensable tool for anyone who loves the art of sewing. Whether you are a beginner or an experienced seamstress, having a high-quality sewing machine can make all the difference in your projects. One popular type of sewing machine that is favored among many sewing enthusiasts is the HD sewing machine.

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machinePrice Range

...

Sling sewing machine 【Sling sewing machine】

Read More- Sling sewing machine

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineOne of the biggest differences is in the motor. Heavy duty machines need to power through thick, layered, or dense fabrics without straining, so they have more powerful motors. Motors in heavy duty machines often range from 1 to 5 amps, while standard motors are usually around 1 amp or less. With the stronger motor, heavy duty machines can sew for longer periods without overheating or losing power. This makes them ideal for sewing operations like upholstery where seams need to go through multiple fabric layers.

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineConclusion

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineThe Pricing Spectrum

...

Sling sewing machine 【Sling sewing machine】

Read More

Popular articles

Upholstery work is an art form, combining creativity with technical skill to transform furniture and other objects into beautiful, functional pieces. For anyone looking to excel in this craft, having the right tools is essential. Among these tools, a heavy-duty upholstery sewing machine stands out as a crucial investment for both hobbyists and professional upholsterers alike.

The technological evolution of threaders has also played an essential role in making sewing accessible to everyone. Modern designs include automatic needle threaders that take the effort out of the process altogether. These devices often feature buttons that, when pressed, quickly accomplish the task of threading without the need for painstaking manual effort. This is particularly advantageous for individuals with physical limitations or those who sew in large volumes, such as in the fashion industry or for charitable sewing projects.

Maintenance

One of the key advantages of automatic quilting machines is their speed. These machines can quilt much faster than a person could ever stitch by hand, allowing for more quilts to be produced in a shorter amount of time. This is especially useful for businesses that need to mass-produce quilts or for individuals who want to quickly finish a project. By using an automatic quilting machine, the entire quilting process is streamlined and expedited.

- Material Compatibility The material of the FIBC should be compatible with the substances being handled to avoid contamination. Spout rossettes made from high-quality materials that resist abrasion are essential for longevity.

A Guide to Beginner Heavy Duty Sewing Machines

Latest articles

-

Additionally, the portability of hand crank leather stitching machines adds to their appeal. Many models are compact and lightweight, making them easy to transport to craft fairs, workshops, or even while traveling. This feature enables leather artisans to demonstrate their skills or work on projects in various settings, fostering a sense of community among fellow crafters.

-

-

Heavy-duty and industrial sewing machines each cater to their unique set of requirements. While industrial machines are designed for specialized, high-volume work, heavy-duty machines sit in a versatile middle ground. They are robust enough to handle rigid materials, but are they adaptable to lighter fabrics?

-

Understanding Zig Zag Embroidery

-

These machines are equipped with multiple needles and thread options, enabling them to work with a variety of materials, from leather to synthetics. Some models even possess the capability to perform specialized stitching techniques that were traditionally challenging to execute, thereby expanding the possibilities for shoe design.

-

The Mechanism Behind Chain Stitch Machines

Links

6. Bearing Assemblies

Understanding the Role of Propeller Pumps in Various Applications

In firefighting systems, propeller pumps also play a crucial role. They provide the necessary pressure and volume of water needed to combat fires effectively. Their capability to move large quantities of water quickly makes them a reliable choice for fire departments, particularly in high-risk areas where rapid response is critical.

Casting slurry pump parts are designed to withstand the rigors of handling abrasive materials, but they too require careful monitoring and timely replacement. The quality of the casting, the material used, and the operating conditions all influence the wear rate of these parts. By selecting high-quality casting slurry pump parts and implementing a regular inspection routine, you can better manage wear and optimize the replacement cycle. This approach ensures that your pump continues to operate efficiently, even in demanding environments, and helps to avoid costly breakdowns.

Comparing Vertical and Horizontal Pumps: Key Considerations

High pressure vertical pumps are designed to handle fluids at high pressures and are often used in applications where space is limited. These pumps are typically installed vertically, which allows them to have a smaller footprint compared to their horizontal counterparts. The vertical design is particularly advantageous in environments where floor space is at a premium, such as in high-rise buildings or industrial plants with constrained layouts. These pumps are known for their ability to deliver high pressure with minimal energy consumption, making them an efficient choice for systems that require constant, reliable pressure. By optimizing the design of high pressure vertical pumps, engineers can ensure that these pumps provide robust performance in demanding applications.

- **Particle Size: Identify the maximum particle size in the slurry.

1. Understand Your Application Requirements

- Throat Bush: Protects the area around the impeller eye where the slurry first enters.

Monitoring Wet Parts for Optimal Pump Performance

Types:

Vertical slurry pumps are essential in various industries where deep pits, sumps, and high liquid levels present unique challenges. The vertical design offers several advantages, including a compact footprint, ease of installation, and simplified maintenance. This article explores how vertical multistage centrifugal pumps and vertical inline centrifugal pumps can be optimized to perform effectively in demanding deep pit environments, focusing on structural engineering solutions.

- Choose materials that can withstand the slurry's abrasiveness and corrosiveness. Common materials include high-chrome alloys, stainless steel, and rubber linings.

Wear Factors: These components experience wear from the slurry and need to be checked regularly.

The vertical design of slurry pumps offers numerous advantages for deep pit applications, from a compact footprint and ease of installation to enhanced durability and simplified maintenance. Vertical multistage centrifugal pumps are particularly well-suited to these environments, where space constraints, high pressures, and abrasive conditions are common. By focusing on structural engineering and optimizing the design of these pumps, industries can ensure reliable performance and cost-effective operation in even the most challenging deep pit applications.

Understanding the Basics of High Pressure Vertical Pumps

- If needed, consult with industry experts or engineers to validate your selection and ensure optimal performance.

Moreover, the volute's cross-sectional area is carefully calculated to match the flow rate and pressure requirements of the system. An oversized volute may lead to low efficiency, as the fluid may not maintain its velocity to generate adequate pressure. Conversely, a volute that is too small can cause excessive pressure buildup, risking damage to the pump and downstream equipment.

b. Impeller Design:

3. Casing

- Volute Liners: Protect the pump casing in the volute section.

- **Particle Size: Identify the maximum particle size in the slurry.

- Decide between direct drive, belt drive, or variable speed drive based on your application needs.

In deep pit and high liquid level applications, pumps must withstand significant pressures and abrasive conditions. High pressure vertical pumps are specifically designed to handle these challenges. Their robust construction and ability to operate under high pressures make them ideal for transporting slurry from deep pits or sumps. These pumps are engineered to resist wear and tear, ensuring a longer service life even in harsh conditions. By focusing on the durability and pressure-handling capabilities of high pressure vertical pumps, engineers can optimize their design for deep pit applications, ensuring consistent performance and reducing the need for frequent maintenance.

a. Performance Curves:

6. Consult with Experts

Another aspect to consider is the volute's performance under varying operational conditions. Centrifugal pumps are often designed to handle specific flow rates and pressures. When the operational conditions stray from those design limits, the volute may not perform optimally, leading to efficiency losses. Engineers often employ computational fluid dynamics (CFD) simulations to analyze and optimize volute designs based on anticipated operational scenarios.

Materials: Liners are often made from high-chrome alloys, rubber, or other wear-resistant materials.