walking foot sewing machine

Latest articles

walking foot sewing machine...

walking foot sewing machine 【walking foot sewing machine】

Read More

walking foot sewing machineTime is often of the essence in the marine industry. Professionals need to complete projects swiftly without compromising quality. The long arm sail sewing machine with a puller significantly increases sewing speed and efficiency by simplifying complex tasks that would typically require multiple operators or additional equipment. The ease of handling bulk fabrics means that a single operator can manage larger projects alone, which reduces labor costs and streamlines the workflow.

...

walking foot sewing machine 【walking foot sewing machine】

Read More

walking foot sewing machineAs CNC technology continues to evolve, we can expect even more innovations in machine sewing. The introduction of artificial intelligence (AI) and machine learning could lead to smarter machines that learn from previous tasks, improving accuracy and efficiency over time.

...

walking foot sewing machine 【walking foot sewing machine】

Read More

walking foot sewing machine...

walking foot sewing machine 【walking foot sewing machine】

Read Morewalking foot sewing machine

...

walking foot sewing machine 【walking foot sewing machine】

Read More

...

walking foot sewing machine 【walking foot sewing machine】

Read More3. Speed Using an overlock machine is typically faster than conventional sewing machines for finishing seams. For garment production, this speed can be an invaluable asset, enabling sewists to complete projects efficiently.

walking foot sewing machine

...

walking foot sewing machine 【walking foot sewing machine】

Read More The Cub Leather Sewing Machine A Tailored Solution for Leather Enthusiasts

walking foot sewing machine

...

walking foot sewing machine 【walking foot sewing machine】

Read MoreOne of the key advantages of double needle stitching is its ability to create a professional-looking finish on garments. The parallel lines of stitching give a clean and polished appearance to the seam, making it ideal for garments that require a neat and tidy finish. Double needle stitching is commonly used on hemlines, cuffs, and collars, as well as on seams that are subjected to a lot of stress, such as in denim jeans.

walking foot sewing machine...

walking foot sewing machine 【walking foot sewing machine】

Read MoreAn overlocker, also known in some regions as a serger, is a specialized sewing machine that plays a crucial role in the world of garment construction and fabric finishing. Unlike traditional sewing machines that simply stitch two pieces of fabric together, overlockers provide a range of functions that not only enhance the aesthetic quality of a garment but also increase its durability and professionalism. This article explores the various capabilities and advantages of using an overlocker in fabric work.

walking foot sewing machine

...

walking foot sewing machine 【walking foot sewing machine】

Read MorePopular articles

- 3. Join a Community Consider joining local workshops or online forums. Engaging with other leatherworkers can provide inspiration and valuable insights.

Features of Zig Zag Sewing Machines

The single needle lockstitch sewing machine operates using a straightforward mechanism that employs one needle and two threads one from the spool and the other from a bobbin. The needle pierces the fabric, and as it retracts, the bobbin thread interlocks with the needle thread to form a lockstitch. This stitching method is not only strong and durable but also produces a neat and professional finish, making it the preferred choice for many types of sewing projects.

Chain stitch machines are often equipped with multiple threads, allowing them to create intricate patterns and stitches. The capability to adjust thread tension ensures that the final product maintains a high level of quality, with seams that don’t easily unravel, even under stress. This feature is particularly important in the production of clothing and textiles that endure rigorous use.

Latest articles

-

Despite the advancements, bulk bag sewing machines also face challenges. The need for regular maintenance and training for operators remains critical to ensure that machines run smoothly and efficiently. Additionally, factors such as fluctuating raw material prices and increasing competition require manufacturers to innovate continually and find cost-effective solutions.

-

4. Capacity to Handle Heavy Materials Leather is known for its resistance and thickness, which can be a challenge for many sewing machines. Manual leather sewing machines are often designed with robust mechanisms that can handle the heft of leather without jamming or breaking needles. This capability makes them ideal for crafting a wide range of leather products.

-

Furthermore, the geographical location and the availability of skilled technicians for machine maintenance and repair also influence prices. In regions where specialized services are scarce, the overall cost of owning an auto sewing machine may increase due to the added expenses of maintenance and repairs.

-

In conclusion, the use of handheld sewing machines for thick fabrics is a growing trend that combines convenience with creativity. As technology progresses and more innovative models hit the market, we can anticipate even greater capabilities that allow crafters to explore their skills with various materials. By understanding the specific requirements of working with thick fabrics and investing in the necessary tools, sewing enthusiasts can unlock the potential of handheld sewing machines, making sewing a more accessible and enjoyable activity for everyone. Whether you're repairing a favorite pair of jeans or creating custom upholstery, these devices are equipped to handle the task, bringing vibrant creativity into the world of sewing.

-

One of the primary functions of a serger is to finish the raw edges of fabric. The machine uses multiple threads to create a tight stitch around the edges, which helps prevent fraying. This is especially useful when working with knit fabrics, which can easily unravel if not properly finished. By serging the edges, you can ensure your garments have a polished and professional look, saving you from the hassle of having to zigzag stitch or use bias tape on each project.

-

One of the key features of our pattern sewing machines is their versatility. With adjustable stitch length and width, as well as the ability to change needle positions, you can customize your stitches to fit any project. Whether you are working with lightweight fabrics like silk or heavy-duty materials like denim, our machines can handle them all with ease.

Butyl rubber is a heavy-duty adhesive that instantly adheres quickly and easily to most surfaces, even those like outside decks where moisture is a factor. Butyl tape is compatible with these surfaces:

Single-side butyl tape works great when you need to bond two objects together whereas the latter can be used as a sealant or gasket. Plus, it's also available in various colors that make certain applications even easier!

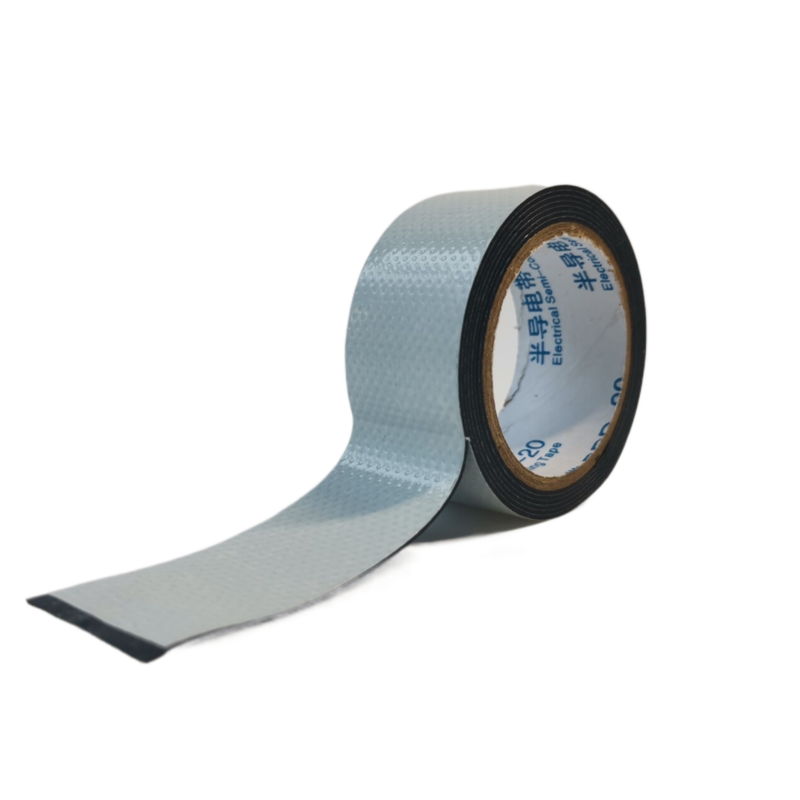

Polyethylene Rubber Tape, also known as PE rubber tape, is a type of adhesive tape that combines the properties of polyethylene and rubber to create a versatile and durable tape suitable for various applications. It is typically used for sealing, insulating, and protecting surfaces in industries such as plumbing, construction, electrical, and automotive.

Aerospace:The aerospace industry also takes advantage of the properties of butyl sealant tape by using it to seal joints, seams, and gaps in aircraft components.

Colour: Black

How to Apply Butyl Rubber Sealant Tape

Widths range from one-half of an inch (12 millimeters) to 6 inches (144 millimeters), and available colors are:

Butyl Rubber Tape Product Applications

One of the standout features of Flex Tape is its ability to conform to irregular surfaces. Whether you're dealing with a smooth surface or something more textured, Flex Tape adheres effectively, ensuring a tight seal. Additionally, its waterproof properties mean that it can be used in wet conditions, making it suitable for both plumbing emergencies and outdoor repairs.

Another area where self-bonding rubber tape excels is in automotive applications. Mechanics and car enthusiasts alike have found this tape to be indispensable for bundling wires, securing hoses, and providing insulation to electrical systems in vehicles. Its resilient nature ensures that it can remain intact even under the high temperatures and vibrations often experienced in a car's engine compartment.

Varnish cambric electrical insulation tape is made of straight-cut woven cotton fabric. Its fabric is primed with oil and coated in an electrical insulating finish. The varnish ensures that the tape remains intact as currents pass through the wire.

Conclusion

One of the key characteristics of PVC black tape is its excellent electrical insulation properties. It is widely used in electrical work to insulate wires and connections, protecting against short circuits and enhancing safety. The tape is designed to withstand a range of temperatures and resist moisture, ensuring that it retains its adhesive properties and protective capabilities even in challenging environments. This makes it an essential material for electricians and technicians who require reliable tools to ensure the safety and efficacy of their work.

When choosing a wiring loom wrap for a vehicle, it is important to consider the specific requirements of the wiring system, as well as the environmental conditions in which the vehicle will be operating. A high-quality wiring loom wrap can help to extend the life of the vehicle's electrical system, and ensure that it operates safely and efficiently for years to come.

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.

flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.Elite Tape offers polyethylene backed film tapes with rubber adhesive systems, also commonly known as PE tapes. This product is highly versatile and used in several applications for sealing, bonding, wrapping, splicing and surface protection. The PE film backing is conformable and easy to work with and offers a rubber adhesive system that is aggressive with immediate bond but removes cleanly from most surfaces. One of the applications where Polyethylene Tapes excel is as a vapor barrier tape due to their strong chemical and moisture resistance.