...

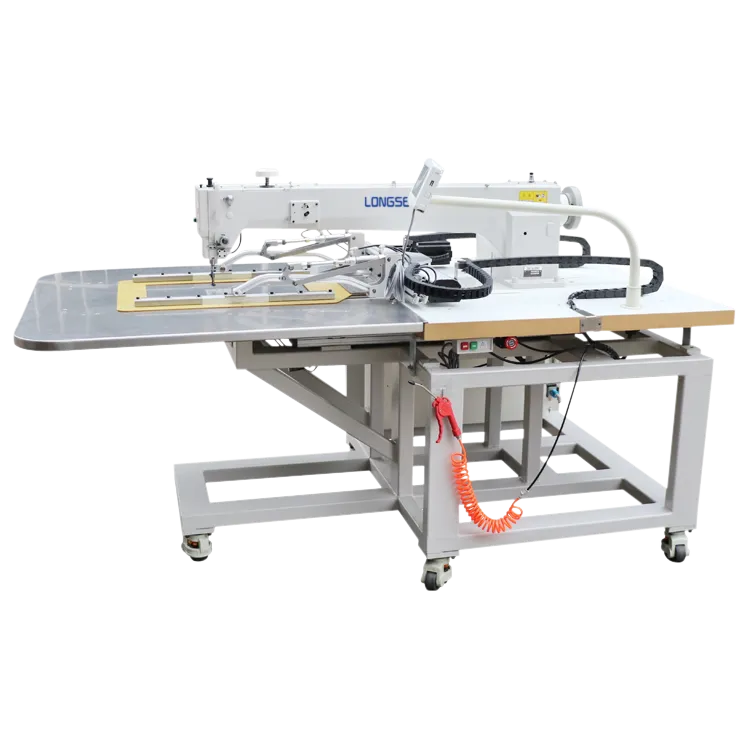

Leather sewing machine 【Leather sewing machine】

Read MoreIf you are in the market for a leather stitcher, look no further! There are plenty of options available for sale that can meet your needs and help you create beautiful leather products.

Leather sewing machine...

Leather sewing machine 【Leather sewing machine】

Read MoreIn the realm of manufacturing, the demand for durable and versatile packaging solutions has seen significant growth, particularly in industries such as agriculture, construction, and food processing. One of the most pivotal innovations in this area is the woven sack bag sewing machine. This specialized equipment plays an essential role in the production of woven polypropylene and polyethylene sacks, which are widely used for packing grains, fertilizers, and various bulk materials.

Leather sewing machine

...

Leather sewing machine 【Leather sewing machine】

Read More