automatic zig zag sewing machine

Latest articles

automatic zig zag sewing machine- Home Décor From curtains to pillowcases, the lock stitch is the go-to method for constructing various home textile items, where durability is essential.

...

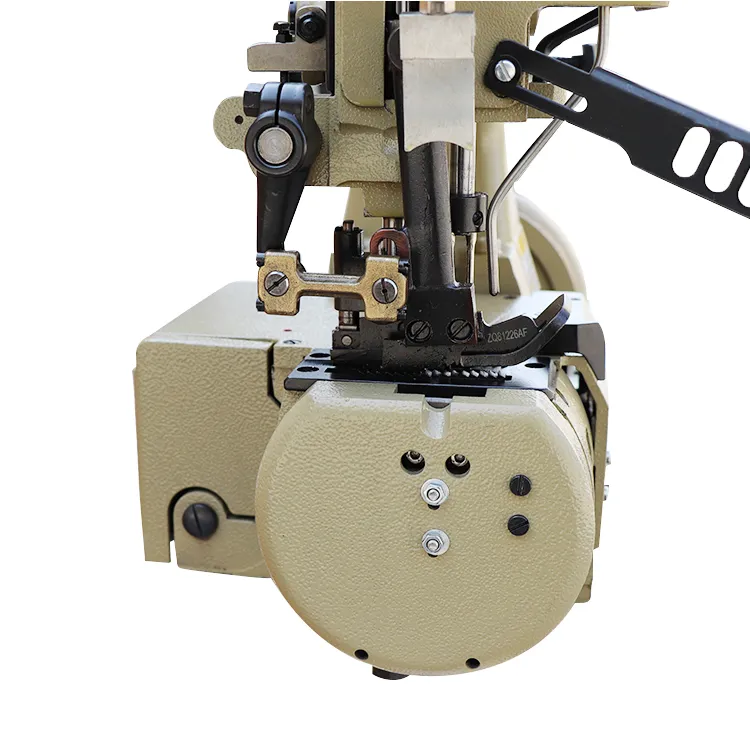

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read More

automatic zig zag sewing machineHowever, while automatic template sewing machines offer numerous advantages, they are not without their challenges. Initial investment costs can be high, making them less accessible for small businesses or individual crafters. Additionally, there is a learning curve associated with mastering these machines, which may deter some users. Nevertheless, as more people become accustomed to technology in their daily lives, these barriers are gradually being overcome.

...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read More

automatic zig zag sewing machine4. Creating Ruffles or Gathered Edges Some sergers come equipped with features that allow for ruffling or gathering. This capability is particularly useful in fashion design, where decorative, textured effects are often required.

...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read More

automatic zig zag sewing machineEnhanced Stitching Patterns

...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read More

automatic zig zag sewing machineIn the ever-evolving world of textile and fashion industries, precision and efficiency are paramount. One of the modern innovations that cater to these demands is the double needle sewing machine. This versatile tool has gained popularity among professionals and hobbyists alike due to its ability to produce high-quality stitches and streamline the sewing process.

...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read More

...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read MoreAn automatic leather sewing machine is a sophisticated device designed specifically for the robust demands of leatherwork. It operates with a level of automation that surpasses its manual counterparts, reducing human effort while enhancing productivity. Unlike traditional machines, these automatic models are equipped with cutting-edge features like computerized controls, programmable stitching patterns, and automatic thread tension adjustment.

automatic zig zag sewing machine...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read More2. Inserting the needle To insert a twin stretch needle, simply remove the regular needle from your machine and insert the twin needle in its place. Make sure that the flat side of the needle is facing towards the back of the machine and that the needles are properly seated in the needle clamp.

automatic zig zag sewing machine...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read MoreCompact Design:

automatic zig zag sewing machine

...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read More 4. Batch Sewing Projects

what can i do with a serger

automatic zig zag sewing machine

...

automatic zig zag sewing machine 【automatic zig zag sewing machine】

Read MorePopular articles

Caring for Chrome Sewing Machine Needles

In addition to its convenience, arm sewing also offers a unique tactile experience that is not found with traditional sewing machines. By using your arms to create stitches and seams, you are able to feel the fabric more intimately and develop a deeper connection with your work. This hands-on approach can be incredibly satisfying and meditative, allowing you to fully immerse yourself in the creative process.

In the world of fashion, precision, efficiency, and creativity are paramount. One of the most groundbreaking innovations that has emerged to enhance these aspects is the double tailor machine. This advanced piece of equipment not only streamlines the sewing process but also offers a range of features that make it indispensable for modern garment production.

1. Elasticity One of the most defining features of the overlock chain stitch is its inherent stretch. This is particularly beneficial when working with fabrics that are prone to stretching, such as jersey or spandex. The stitch can accommodate the movement of the garment without breaking or causing stress on the seams.

Latest articles

-

In the ever-evolving landscape of textile manufacturing, the industrial walking foot machine has emerged as a transformative tool. Traditionally, sewing machines have played a crucial role in fabric production, but the advent of walking foot technology has enhanced the efficiency, precision, and versatility of sewing operations, particularly in heavy and layered materials.

-

The spark plug ignition coil works by converting the low voltage electricity from the battery into a much higher voltage that is capable of creating a spark across the spark plug gap. This high voltage is delivered to the spark plug through the ignition coil wire, which is connected to the secondary winding of the ignition coil.

One way to recognize an improperly installed seal is by checking whether or not there is uneven shearing of the rubber after use. If this is evident, adjust by aligning the installation tools properly before pressing the seal into place.

Oil seals are used in a great many devices for steel production equipment.

Figure 7 shows the places where each seal type is used in a rolling mill.

Reinforced GVP design for larger diameters, with rotation speeds of up to 15 m/s and pressure of 3-4 bar

The sealing element makes up the interior of the oil seal, and the materials commonly used are:

When they are subjected to hot & pressured oil, or hot & pressured gas, they will compress. These seals reduce in size and become more compact. Afterward, they store the mechanical energy generated by the heat and pressure, which is why they can maintain a leak-proof mating surface.

Most oil seals consist of some basic elements that configure their structure, such as the sealing element, the metal case, and the spring:

When the requested S-DUO type is not available, two S-types can be filled back to back

The metal used in the outer case of oil seals is usually made of carbon steel. Upon request, and depending on quantities, a different type of steel (such as stainless steel) can be used.

While changing spark plugs is a task that some vehicle owners may undertake themselves, many opt for professional mechanics to ensure proper fitting and function While changing spark plugs is a task that some vehicle owners may undertake themselves, many opt for professional mechanics to ensure proper fitting and function

While changing spark plugs is a task that some vehicle owners may undertake themselves, many opt for professional mechanics to ensure proper fitting and function While changing spark plugs is a task that some vehicle owners may undertake themselves, many opt for professional mechanics to ensure proper fitting and function spark plugs cost. Labor costs can vary widely depending on the complexity of the engine and the hourly rate of the mechanic.

spark plugs cost. Labor costs can vary widely depending on the complexity of the engine and the hourly rate of the mechanic. Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly