...

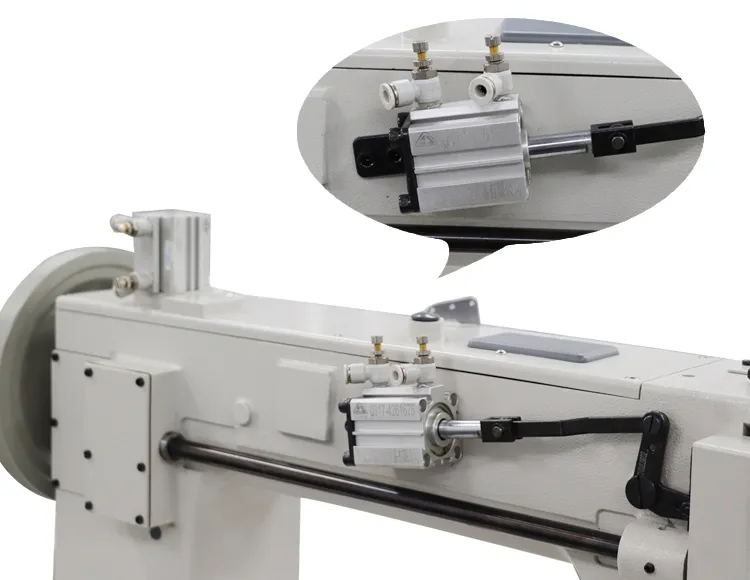

Big bag sewing machine 【Big bag sewing machine】

Read MoreThe versatility of the Union Lockstitch Sewing Machine is another reason for its continued popularity. It is commonly used in the apparel industry for creating garments, but its applications extend far beyond clothing. Upholstery shops utilize it for furniture and home decor projects, while industrial applications include producing textiles for automotive and medical uses.

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read More

Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine

Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine Traditional spark plugs are prone to wear and tear due to the constant exposure to extreme temperatures and corrosive chemicals within the engine