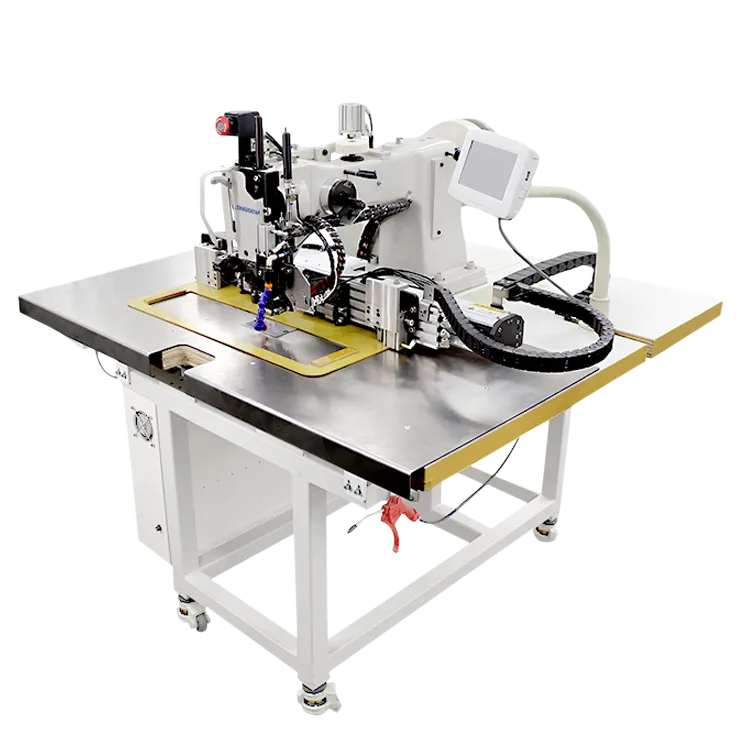

double needle sewing machine for leather

Latest articles

double needle sewing machine for leatherThe Art and Craft of Quilting Machine Embroidery Designs

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read More

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read Moredouble needle sewing machine for leather

...

double needle sewing machine for leather

【double needle sewing machine for leather】

Read More

Conclusion

double needle sewing machine for leather

...

double needle sewing machine for leather

【double needle sewing machine for leather】

Read MoreA serger machine, also known as an overlock machine, is designed to stitch and finish the edges of fabric in a single pass. Unlike traditional sewing machines, sergers use multiple threads to create a secured seam and can simultaneously trim excess fabric. This unique functionality not only saves time but also enhances the quality of the final product, making sergers an essential tool for anyone serious about garment construction or fabric crafting.

double needle sewing machine for leather

...

double needle sewing machine for leather

【double needle sewing machine for leather】

Read More

what is a heavy duty sewing machine. The solid construction of heavy-duty machines ensures that they won't wobble or shift while sewing, allowing for precise and accurate stitching every time. Another important feature of heavy-duty sewing machines is their specialized stitching options. These machines often come with a variety of built-in stitches, including straight stitches, zigzag stitches, and decorative stitches, allowing you to customize your sewing projects to your liking. Some heavy-duty machines also come with specialty stitches such as buttonhole stitches and quilting stitches, making them versatile tools for a wide range of sewing tasks. Overall, a heavy-duty sewing machine is a valuable investment for anyone who frequently works with heavy fabrics or requires a durable and reliable machine for their sewing projects. Whether you're a professional seamstress, a hobbyist crafter, or a DIY enthusiast, a heavy-duty sewing machine can help you tackle tough sewing tasks with ease and precision. With its powerful motor, sturdy construction, and specialized features, a heavy-duty sewing machine is a must-have tool for anyone looking to take their sewing projects to the next level.

double needle sewing machine for leather

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read More Conclusion

double needle sewing machine for leather

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read MoreA serger machine, also known as an overlock machine, is designed to stitch and finish the edges of fabric in a single pass. Unlike traditional sewing machines, sergers use multiple threads to create a secured seam and can simultaneously trim excess fabric. This unique functionality not only saves time but also enhances the quality of the final product, making sergers an essential tool for anyone serious about garment construction or fabric crafting.

double needle sewing machine for leather

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read More

what is a heavy duty sewing machine. The solid construction of heavy-duty machines ensures that they won't wobble or shift while sewing, allowing for precise and accurate stitching every time. Another important feature of heavy-duty sewing machines is their specialized stitching options. These machines often come with a variety of built-in stitches, including straight stitches, zigzag stitches, and decorative stitches, allowing you to customize your sewing projects to your liking. Some heavy-duty machines also come with specialty stitches such as buttonhole stitches and quilting stitches, making them versatile tools for a wide range of sewing tasks. Overall, a heavy-duty sewing machine is a valuable investment for anyone who frequently works with heavy fabrics or requires a durable and reliable machine for their sewing projects. Whether you're a professional seamstress, a hobbyist crafter, or a DIY enthusiast, a heavy-duty sewing machine can help you tackle tough sewing tasks with ease and precision. With its powerful motor, sturdy construction, and specialized features, a heavy-duty sewing machine is a must-have tool for anyone looking to take their sewing projects to the next level.

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read MoreAdditionally, sewing your own car mats can be a cost-effective solution. While premium mats available in the market often come with high price tags, homemade versions can save money without sacrificing quality. The DIY approach allows for creativity and personalization without the premium price attached to many commercial products.

double needle sewing machine for leather

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read MoreWhen it comes to sewing, having the right machine is crucial. For both beginners and experienced seamstresses alike, a heavy-duty home sewing machine is an invaluable asset that can elevate your craft to new heights. These machines are specifically designed to handle a variety of fabrics and projects, making them a popular choice for anyone looking to tackle larger or more complex sewing tasks.

double needle sewing machine for leather

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read More Where to Find Double Needle Walking Foot Sewing Machines for Sale

double needle sewing machine for leather

...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read More...

double needle sewing machine for leather 【double needle sewing machine for leather】

Read More Popular articles

The price of zigzag sewing machines can vary widely depending on the above factors. Entry-level machines are typically priced between $100 to $300. These models often provide basic zigzag functionality suitable for beginners and light sewing tasks. Mid-range machines usually cost between $300 to $700 and include more advanced features, making them suitable for hobbyists and semi-professionals. High-end machines, which may be priced from $700 to over $2,000, are designed for serious sewing enthusiasts and professionals, offering extensive features, durability, and high performance.

- Another benefit of using a universal walking foot sewing machine is its versatility

1. Standard Foot This is the most common presser foot, ideal for general sewing tasks. It works well for straight stitching and basic construction, making it suitable for beginners learning to sew.

The construction of chain stitch sewing machines often involves multiple needles and loopers, allowing for greater efficiency in production. Many models are designed with enhanced speed capabilities, enabling manufacturers to meet high-volume demands without compromising quality. This is crucial in today’s fast-paced fashion environment, where trends change rapidly, and timely delivery can make or break a label's success.

Durability

Enhanced Efficiency

1. Enhanced Efficiency One of the primary advantages of using industrial bag closing machine heads is the significant increase in production speed. Automated systems can close hundreds or thousands of bags per hour, reducing labor costs and increasing overall throughput. This efficiency is especially crucial in high-demand industries such as food processing, agriculture, and chemicals.

industrial bag closing machine head

If you are a fan of vintage styles and classic designs, the Singer Tradition Sewing Machine is a great option. With its timeless look and durable construction, this machine is a reliable choice for those who value tradition and nostalgia in their sewing equipment. And with special deals and discounts available, there has never been a better time to invest in this classic machine.

sewing machine specials

Links

The car head gasket, also known as the cylinder head gasket, is a critical sealing component in the engine that plays a pivotal role in maintaining the integrity of the combustion chamber. This gasket is designed to seal the cylinder head to the engine block, preventing the leakage of coolant, oil, and combustion gases. A properly functioning car head gasket is essential for ensuring optimal engine performance, preventing overheating, and maintaining the overall efficiency of the engine.

Hub oil seals are essential components in automotive and industrial systems, serving to maintain the integrity of the wheel hub assembly. These seals prevent the leakage of lubricating oil and the entry of contaminants, safeguarding the wheel bearings and other internal components. In industrial applications, hub oil seals contribute to the smooth operation and reliability of machinery, ensuring optimal performance and safety.

Oil seals are used in a great many devices for steel production equipment.

Figure 7 shows the places where each seal type is used in a rolling mill.

Oil Seals Enable Your Equipment to Operate Efficiently

1. What are oil seals?

spark plug use. Over time, plugs can become fouled with carbon deposits or damaged by normal wear and tear. Symptoms of misfiring or reduced engine efficiency often indicate the need for inspection or replacement. Regular checks allow for timely intervention, preventing more significant issues down the line.

spark plug use. Over time, plugs can become fouled with carbon deposits or damaged by normal wear and tear. Symptoms of misfiring or reduced engine efficiency often indicate the need for inspection or replacement. Regular checks allow for timely intervention, preventing more significant issues down the line.

Figure 4.4. Scanning electron microscope (SEM) image of the surface quenched for (A) uncured rubber and (B) transmission electron microscope (TEM) image for cured rubber [64].

Oil seals come in various shapes to fit the machine or substance for sealing.

For this reason, when designing a machine, it is important to select the oil seal that is right for that machine.

Next time, we will explain the key points to consider when selecting your oil seal.

: guarantees dynamic and static sealing.

Conversely, a decrease in demand can lead to a surplus of oil seals, which can drive prices down Conversely, a decrease in demand can lead to a surplus of oil seals, which can drive prices down

Conversely, a decrease in demand can lead to a surplus of oil seals, which can drive prices down Conversely, a decrease in demand can lead to a surplus of oil seals, which can drive prices down oil seal price.

oil seal price.