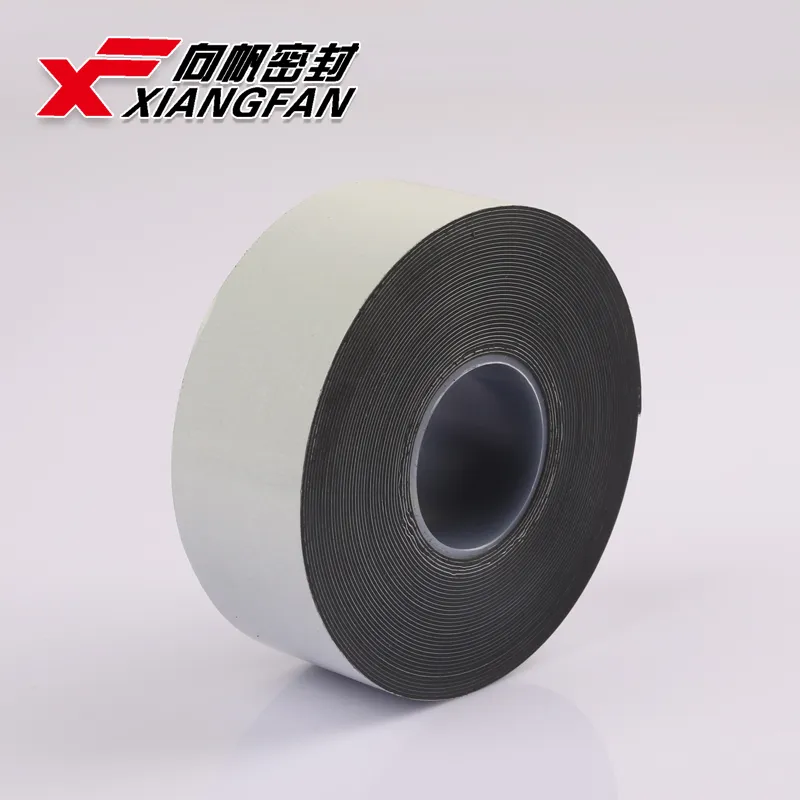

However, they may not perform as well in high-temperature scenarios compared to rubber tape However, they may not perform as well in high-temperature scenarios compared to rubber tape

However, they may not perform as well in high-temperature scenarios compared to rubber tape However, they may not perform as well in high-temperature scenarios compared to rubber tape insulation tape types.

insulation tape types.Polyethylene film tape (63535) is a 7-mil thick tape coated on one side with a synthetic rubber adhesive. This particular tape is UV-resistant and can form a water-tight seal, making it a good tape for outdoor use. It is designed to be able to mask windows and doors in stucco fabrication and other construction applications. This tape is available in white or red. Available widths range from 2 inches (48 millimeters) to 44 inches (1,118 millimeters).

Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications

Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications