...

automatic buttonhole sewing machine 【automatic buttonhole sewing machine】

Read MoreI was obsessed: The Singer “Heavy Duty” Sewing Machine, which can be found refurbished for as low as $160, was proving difficult to find, thanks to the quarantine crafting boom, and I refused to settle for anything less.

...

automatic buttonhole sewing machine 【automatic buttonhole sewing machine】

Read More...

automatic buttonhole sewing machine 【automatic buttonhole sewing machine】

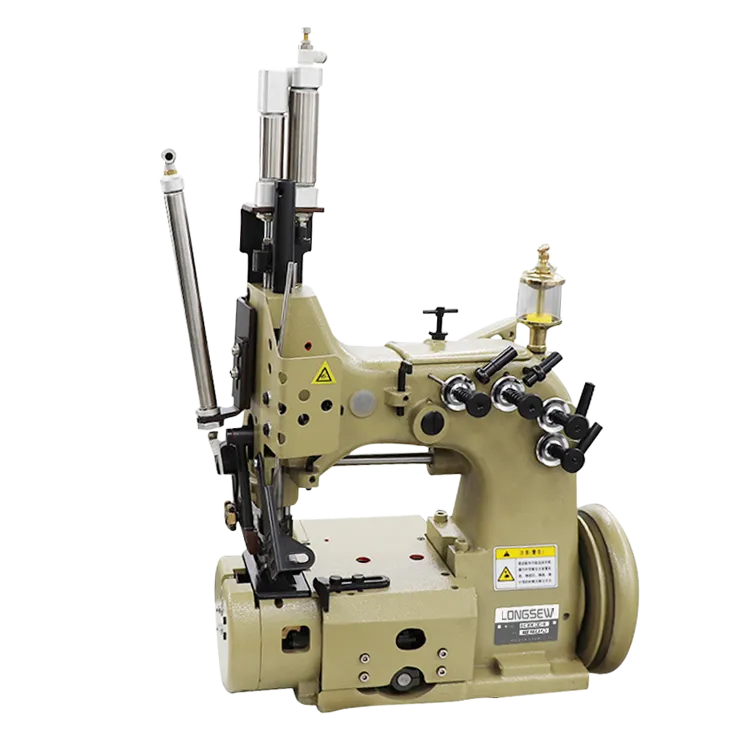

Read MoreIn the fast-paced world of manufacturing and packaging, efficiency and precision are paramount. One of the essential tools in this domain is the bag closer machine, a device designed to seal bags containing a variety of products, from food items to industrial materials. To ensure optimal performance, understanding the various parts of a bag closer machine is crucial.

...

automatic buttonhole sewing machine 【automatic buttonhole sewing machine】

Read More...

automatic buttonhole sewing machine 【automatic buttonhole sewing machine】

Read More...

automatic buttonhole sewing machine 【automatic buttonhole sewing machine】

Read More...

automatic buttonhole sewing machine 【automatic buttonhole sewing machine】

Read More4. User-Friendly Operation With many modern models designed with intuitive interfaces and robust software, operating a two needle embroidery machine has become accessible even for beginners. Comprehensive tutorials and guides often accompany these machines, providing users with the resources needed to get started.

1. Durability One of the primary advantages of utilizing an overlocking machine is the strength it provides to the seams of the carpet. Overlocked edges are less likely to unravel over time, ensuring the carpet retains its integrity even under heavy foot traffic.

2. Presser Feet Options

Understanding Heavy-Duty Machines

1. Practice on Scrap Fabric

Applications of Lock Stitch Machines

4. Improved Seam Strength The two rows of stitches provide additional security to seams, which is critical in ensuring that the garment withstands wear and tear. This reliability is essential as consumers increasingly demand durable products.

The Art and Craft of Double Needle Sewing

Moreover, the integration of CNC technology in stitching machines enhances the overall sustainability of textile production. CNC machines reduce fabric waste through precise cutting and stitching, allowing manufacturers to optimize material usage. This waste reduction not only decreases costs but also lessens the environmental impact of textile manufacturing, aligning with the industry's growing focus on sustainability and ethical production practices.

Historical Context

Oil seals play a critical role in numerous mechanical systems where lubrication is essential for efficient operation. Among the many components that contribute to the overall functionality of machines, oil seals ensure that lubricating oil is contained within the machinery while preventing the ingress of dirt and contaminants. This article delves into the significance of oil seals, particularly examining the implications of 22%, 40%, and 7% in their applications and performance metrics.

What Are Hydraulic Piston Oil Seals?

Applications

Design and Construction

Advanced designs, such as labyrinth seals or double lip seals, enhance this percentage by creating multiple barriers, improving the seal's ability to protect the internal components from damage Advanced designs, such as labyrinth seals or double lip seals, enhance this percentage by creating multiple barriers, improving the seal's ability to protect the internal components from damage

Advanced designs, such as labyrinth seals or double lip seals, enhance this percentage by creating multiple barriers, improving the seal's ability to protect the internal components from damage Advanced designs, such as labyrinth seals or double lip seals, enhance this percentage by creating multiple barriers, improving the seal's ability to protect the internal components from damage 70 90 10 oil seal.

70 90 10 oil seal.Importance of Oil Seals

35 52 7 seal. In numerology, it symbolizes spiritual awareness and enlightenment. It's often associated with luck, perfection, and divine completeness. In many religions, 7 holds a sacred status - from the seven days of creation to the seven chakras in Eastern philosophy. It's a number that resonates deeply, echoing across time and cultures.

35 52 7 seal. In numerology, it symbolizes spiritual awareness and enlightenment. It's often associated with luck, perfection, and divine completeness. In many religions, 7 holds a sacred status - from the seven days of creation to the seven chakras in Eastern philosophy. It's a number that resonates deeply, echoing across time and cultures.3. Clean the Cylinder Thoroughly clean the cylinder body and all parts to remove any debris or old hydraulic fluid.

The typical boom cylinder has rod and gland seals that need to be replaced The typical boom cylinder has rod and gland seals that need to be replaced

The typical boom cylinder has rod and gland seals that need to be replaced The typical boom cylinder has rod and gland seals that need to be replaced excavator boom cylinder seal replacement. Use a seal removal tool to gently extract the old seals without damaging the cylinder bore. Be cautious not to damage the cylinder walls as this could compromise the new seals' effectiveness.

excavator boom cylinder seal replacement. Use a seal removal tool to gently extract the old seals without damaging the cylinder bore. Be cautious not to damage the cylinder walls as this could compromise the new seals' effectiveness.

A rear hub seal is an essential component of a car's rear axle system. It is responsible for keeping the lubricating oil inside the axle housing while preventing dirt, water, and other contaminants from entering. Without a properly functioning rear hub seal, the axle could suffer from lack of lubrication, leading to increased wear and tear on the components and potential failure.

Additionally, custom-designed seals may also carry a premium due to the additional effort required to meet specific customer requirements Additionally, custom-designed seals may also carry a premium due to the additional effort required to meet specific customer requirements

Additionally, custom-designed seals may also carry a premium due to the additional effort required to meet specific customer requirements Additionally, custom-designed seals may also carry a premium due to the additional effort required to meet specific customer requirements oil seal price.

oil seal price.

While shaft oil seals are built to withstand significant wear and tear, they are not impervious to failure. Regular inspection is crucial for identifying signs of wear, such as oil leaks or cracks in the sealing material. Symptoms like these often indicate that it is time to replace the oil seal to avoid further damage to the machinery.

Importance of Quality Seal Kits

4. Follow Torque Specifications When reassembling the pump, adhere to the manufacturer’s torque specifications to avoid damaging the seals or the pump itself.

One of the most important functions of the high pressure oil rail seal kit is to seal the connections between the fuel injectors and the fuel rail. These seals help to ensure that no fuel leaks occur, which could result in poor engine performance or even damage to the fuel system.

Hydraulic Cylinder Seal Replacement A Comprehensive Guide

- Dust Seals These seals act as the first line of defense against external contaminants. They are located outside the cylinder and help keep dirt and debris from entering the hydraulic system.

A hydraulic cylinder packing kit consists of various seals and gaskets designed to prevent fluid leakage and ensure optimal performance of hydraulic cylinders. These kits serve as barriers between the high-pressure hydraulic fluid and the external environment, thus protecting the system from contaminants and maintaining operational efficiency. Packing kits come in various designs and materials, depending on the specific application and operating conditions.

The 35x72x10 oil seal finds prevalent use in various applications across different industries

. Commonly, it is utilized in