sail making machine

The Evolution of Sail Making Machines

Sail making is an ancient craft with a rich history, integral to the development of navigation and maritime trade. As the demand for larger and more efficient sailing vessels grew, so did the need for innovative tools and machinery to aid in sail production. The invention and evolution of sail making machines revolutionized this craft, transforming traditional handcrafting methods into efficient industrial processes.

Historical Background

Before the advent of machinery, sails were meticulously handcrafted by skilled artisans. Each sail was made from individual pieces of fabric that were sewn together, a process that was incredibly labor-intensive and time-consuming. The materials used were often heavy-duty fabrics such as canvas or duck cloth, which provided the durability needed for harsh maritime conditions.

As sailing technology advanced, so did the fabrics and materials used for sails. The introduction of synthetic materials in the mid-20th century offered enhanced durability and performance. This shift in materials necessitated the development of specialized machinery capable of handling these new fabrics while maintaining precision and quality.

The First Sail Making Machines

The first sail making machines were relatively simple compared to modern machinery. Early machines included straight-line sewing machines that allowed for quicker and more consistent stitching of sail panels. However, these initial machines were still limited in functionality and could not accommodate the complex shapes and sizes of modern sails.

As technology progressed, manufacturers began to develop more sophisticated machines. The introduction of automated cutting machines represented a significant milestone in sail production. These machines used computerized templates to precisely cut sail panels, reducing waste and ensuring uniformity across production batches. This level of precision was unattainable in manual methods, where human error could lead to inconsistencies.

Modern Innovations

sail making machine

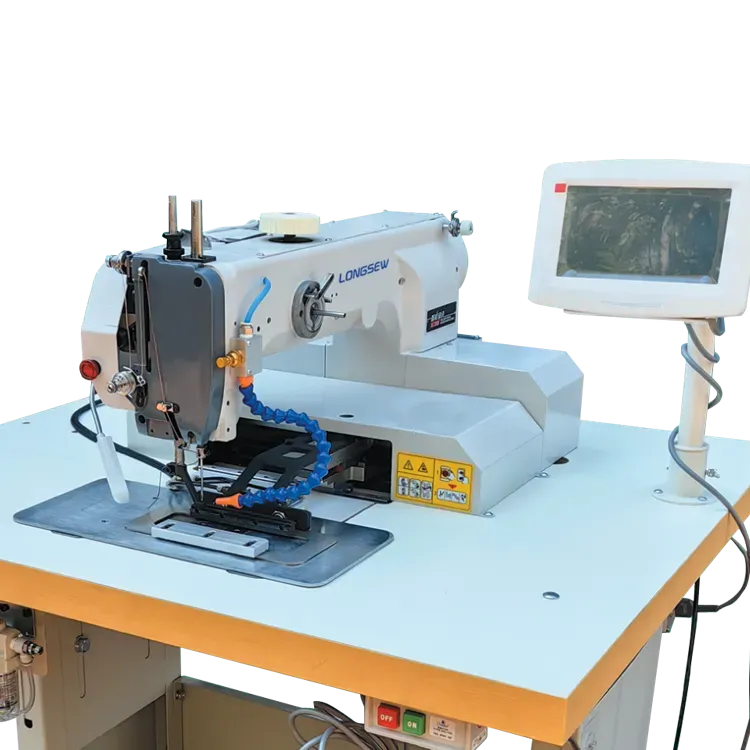

Today’s sail making machines are a testament to the advancement of engineering and technology. Modern sail production facilities utilize a combination of automated and computerized systems to enhance efficiency and improve the quality of the final product. CNC (Computer Numerical Control) machines can create complex sail shapes accurately, allowing sailmakers to experiment with various designs to optimize performance.

Another significant innovation is the introduction of laser cutting technology. This method provides unparalleled accuracy and can cut through multiple layers of fabric simultaneously. This efficiency drastically reduces production time while maintaining the integrity of the materials used. Moreover, laser cutting minimizes fraying, which is crucial for the longevity of sails.

In addition to cutting machines, modern sail making also incorporates advanced sewing machines equipped with specialized features such as high-speed stitching and automatic thread tension control. These machines ensure tight and consistent seams, which are vital for the durability and performance of sails.

Sustainability in Sail Making

As the world becomes more environmentally conscious, the sail making industry is also making strides towards sustainability. Many manufacturers are exploring eco-friendly materials and production techniques. Innovations such as biodegradable fabrics and energy-efficient machinery are becoming more common in the production process. This shift not only benefits the environment but also appeals to the growing demographic of eco-conscious consumers.

The evolution of sail making machines signifies the interplay between tradition and innovation. While the craft of sail making remains rooted in skill and artistry, the introduction of advanced machinery has allowed the industry to meet contemporary demands for quality, efficiency, and sustainability.

Conclusion

In conclusion, the journey of sail making machines from simple stitching devices to complex automated systems reflects the broader technological advancements of society. These innovations have not only streamlined the production process but have also enhanced the performance of sails, ensuring that they are fit for modern maritime challenges. As the industry continues to evolve, the spirit of craftsmanship remains alive, with machines serving as tools to enhance the age-old art of sail making.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025