Sewing Machine for Crafting Durable PP Bags Efficiently and Easily

The Evolution and Significance of PP Bag Sewing Machines

In today’s fast-paced world, the demand for efficient packaging solutions has seen exponential growth. One key player in this field is the polypropylene (PP) bag sewing machine, an advanced piece of equipment designed to enhance the production of durable, lightweight, and versatile bags. This article delves into the significance, working principles, and benefits of PP bag sewing machines in the packaging industry.

Understanding PP Bags

Polypropylene bags are widely recognized for their robustness, moisture resistance, and affordability. These bags are commonly used in various sectors, including agriculture, construction, food packaging, and retail, due to their ability to hold heavy loads while remaining lightweight. The production of these bags involves several steps, and the sewing process is critical for ensuring quality and durability.

The Function of PP Bag Sewing Machines

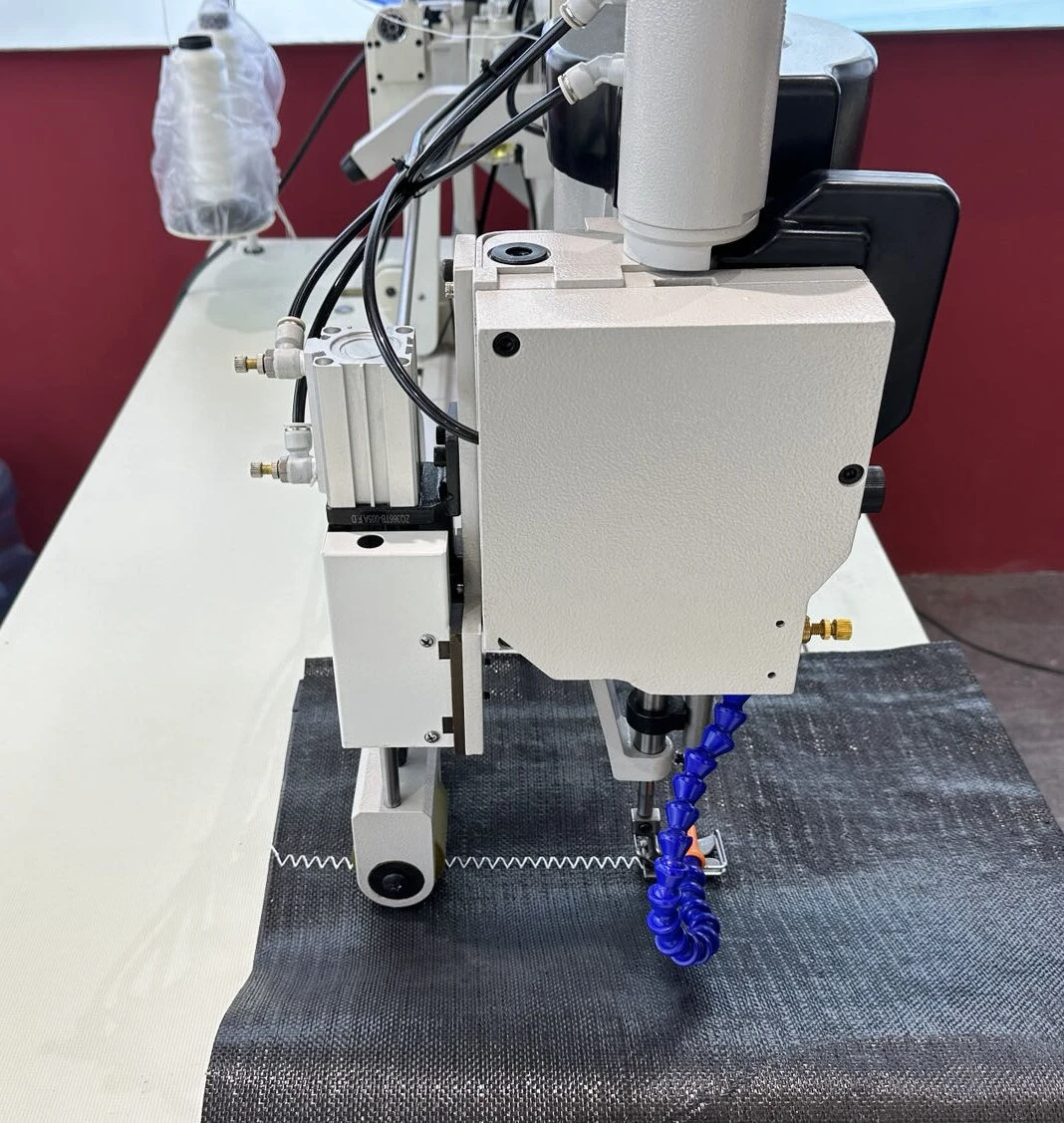

PP bag sewing machines are specialized sewing devices designed to stitch together unsewn edges of polypropylene bags. These machines are engineered for high-speed sewing, allowing for efficient production lines. There are mainly two types of sewing machines used in the manufacturing of PP bags overlock sewing machines and chain stitch sewing machines.

1. Overlock Sewing Machines These machines are excellent for providing a secure, finished seam on the edges of the bag. They utilize multiple threads and stitch the fabric edges together, preventing fraying and providing greater strength.

2. Chain Stitch Sewing Machines Renowned for their speed, these machines use a single needle and a looper to create a strong stitch. Chain stitches can be particularly useful for sewing heavier bags or creating a basting stitch for temporary holds.

Both types of machines play a crucial role in ensuring the integrity of the bags, enabling them to withstand significant weight and environmental factors.

Advantages of Using PP Bag Sewing Machines

Utilizing PP bag sewing machines presents several advantages that contribute to increased productivity and profitability for manufacturers

pp bag sewing machine

1. Efficiency in Production Modern PP bag sewing machines are designed for high output. They can sew multiple bags in a short amount of time, reducing labor costs and improving turnaround times.

2. Precision and Quality Advanced sewing machines come with features that ensure precise stitching. This not only enhances the quality of the bags but also minimizes the chances of product failure due to improper stitching.

3. Versatility These machines accommodate various bag sizes and designs, allowing manufacturers to cater to diverse market needs. This adaptability is essential for staying competitive in a rapidly changing environment.

4. Reduced Manual Labor Automated sewing machines require minimal manual intervention, reducing the chances of human error and lowering labor costs. This also allows workers to focus on more critical tasks, enhancing overall operational efficiency.

5. Durability of End Product Bags sewn with these machines display superior strength and durability. This quality is paramount when it comes to transporting heavy goods or keeping products secure.

Sustainability and the Future of PP Bag Sewing Machines

As concerns about environmental sustainability grow, the packaging industry faces new challenges. Innovative manufacturers are now focusing on creating eco-friendly PP bags, leading to the increased demand for high-efficiency sewing machines that can cater to sustainable practices.

Moreover, advances in technology have led to the development of computerized and automatic sewing machines that can optimize production processes, contribute to waste reduction, and enhance the quality of the finished products.

Conclusion

The PP bag sewing machine has become an indispensable tool in the packaging industry, providing solutions that meet the growing demands for efficient and reliable packaging. As technology advances, these machines will continue to evolve, incorporating features that promote sustainability and adaptability to changing market needs. Manufacturers who invest in high-quality PP bag sewing machines are not only improving their production capabilities but also contributing to a more sustainable and efficient packaging ecosystem. As the industry progresses, the role of these machines will become even more pivotal, shaping the future of packaging solutions.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025