Long Reach and Elevated Sail Fabrication Equipment for Efficient Production

The Long Arm and High Arm Sail Making Machine Revolutionizing Sail Production

In the world of maritime craftsmanship, the production of sails has always held a crucial place. With the surge in recreational sailing and marine sports, the demand for high-quality, durable sails has risen exponentially. This evolution has propelled innovations in sail-making technology, among which the Long Arm and High Arm Sail Making Machine stands out as a game changer. This specialized equipment enhances precision, efficiency, and versatility in sail production, meeting the needs of both professional sail makers and hobbyists alike.

The Long Arm and High Arm Sail Making Machine Revolutionizing Sail Production

Moreover, the high arm feature provides additional clearance, which is especially beneficial when working with complex sail designs that feature curved seams and multiple panels. The ability to manipulate the fabric without restriction means that sail makers can focus on creativity and artistry, rather than being hindered by the limitations of their equipment. This, in turn, leads to more innovative sail designs, tailored to specific sailing conditions or preferences, thus enhancing the overall customer experience.

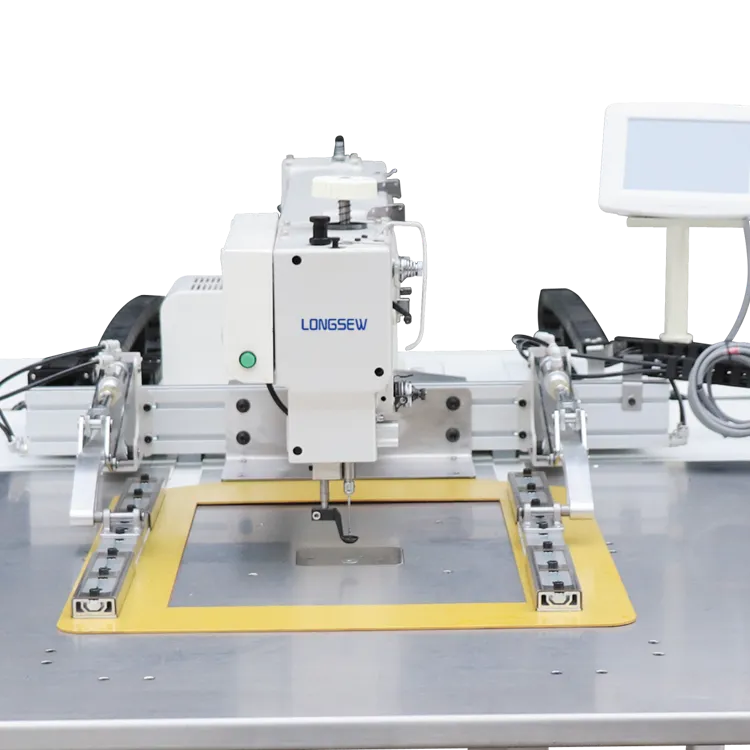

long arm and high arm sail making machine

In addition to its physical advantages, the Long Arm and High Arm Sail Making Machine is equipped with advanced technological features that further streamline the production process. Many modern machines come with computerized systems that allow for precise programming of stitching patterns. This not only increases accuracy but also saves time, as sail makers can produce multiple sails with consistent quality at a faster rate. Features like automatic thread cutting and programmable stitch lengths eliminate many of the manual processes that once made sail production labor-intensive, allowing skilled workers to focus on the more nuanced aspects of sail making.

The machine’s adaptability is also noteworthy. Different types of sails, such as mainsails, headsails, and spinnakers, each have unique requirements that often necessitate specialized stitching techniques. The Long Arm and High Arm Sail Making Machine can be adjusted and calibrated for various types of materials and stitching patterns, making it a versatile tool in any sail maker’s workshop. This adaptability ensures that sail makers can produce a wide range of sails without needing to invest in multiple machines, thus optimizing both space and resources.

Sustainability is another important factor in today’s manufacturing world, and the sail-making industry is no exception. The efficiency of the Long Arm and High Arm Sail Making Machine contributes to reduced wastage of fabric, as the precision of the cuts and stitches minimizes off-cuts and errors. Furthermore, the ability to quickly produce high-quality sails means that repairs and replacements can be made more efficiently, encouraging a more sustainable use of materials over time.

In conclusion, the Long Arm and High Arm Sail Making Machine is a transformative tool that has redefined the landscape of sail production. Its combination of extended reach, advanced technological features, and adaptability not only enhances the craftsmanship involved in making sails but also improves efficiency and sustainability. As the sailing industry continues to evolve, machines like these will undoubtedly play a pivotal role in shaping the future of sail making, providing sailors with the quality and performance they demand on the open waters. Whether for racing or cruising, the significance of such innovations cannot be overstated, as they ensure that the art of sail making remains as vibrant and dynamic as the sport itself.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025