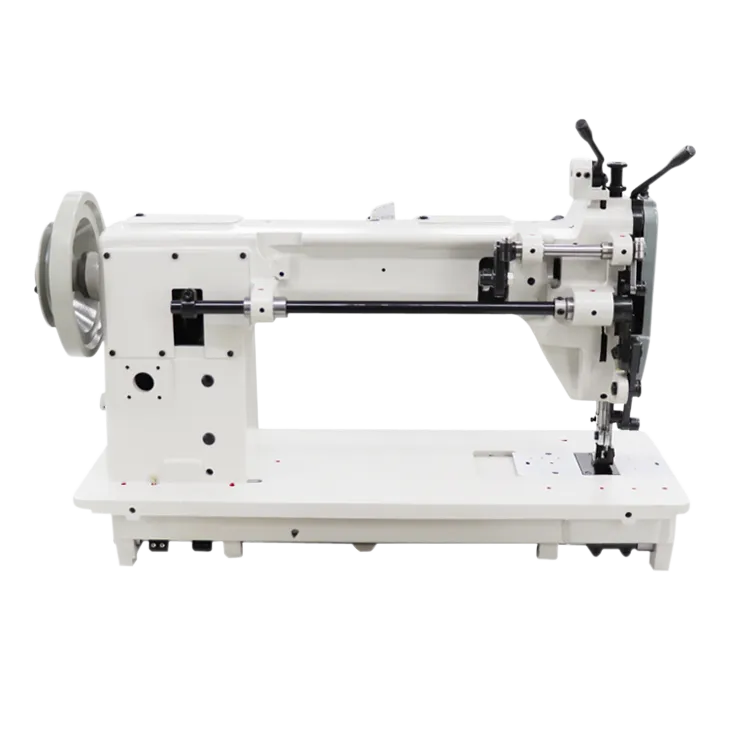

industrial zig zag embroidery machine

Industrial Zig Zag Embroidery Machines Revolutionizing Textile Production

In the rapidly evolving world of textile manufacturing, the demand for innovative techniques that enhance productivity and creativity has never been higher. Among these advancements, the industrial zig zag embroidery machine has emerged as a game-changer. This technology combines versatility with precision, allowing manufacturers to create intricate designs efficiently. This article explores the features, benefits, and applications of industrial zig zag embroidery machines, showcasing their vital role in modern textile production.

Understanding the Zig Zag Stitch

The zig zag stitch is a fundamental element of embroidery, known for its versatility and aesthetic appeal. Unlike straight stitches, zig zag stitches can create various effects, from decorative patterns to durable seams. The ability to alternate between different stitch widths and lengths allows for a vast array of designs, making it a popular choice in diverse applications, from fashion apparel to home textiles.

Industrial zig zag embroidery machines are specially engineered to handle large-scale production while maintaining high-quality output. These machines are equipped with advanced features that enhance their performance, including computerized systems, multiple needle placements, and extensive design libraries.

Key Features of Industrial Zig Zag Embroidery Machines

1. High-Speed Operation Industrial zig zag embroidery machines operate at remarkable speeds, significantly increasing production efficiency. Many models can stitch hundreds of designs per hour, making them ideal for large manufacturing environments.

2. Automated Design Input With the advent of computerized embroidery technology, these machines can accept a wide range of design files from software applications. This feature streamlines the process of creating complex patterns, allowing designers to experiment and modify their creations effortlessly.

3. Multi-Needle Capability These machines often come with multiple needles, enabling the execution of various stitches and colors in a single run. This reduces downtime and enhances productivity, as operators can switch between colors without manual intervention.

4. User-Friendly Interfaces Modern zig zag machines are designed with intuitive interfaces that simplify operation for users. Touchscreen controls and user-friendly software allow operators to quickly learn the machine's functionalities and navigate through designs with ease.

5. Durability and Reliability Built to withstand the demands of industrial environments, these machines are constructed with robust materials and engineering. They offer longevity and consistent performance, reducing the need for frequent repairs and maintenance.

industrial zig zag embroidery machine

Benefits of Using Zig Zag Embroidery Machines

1. Enhanced Design Versatility The ability to create intricate designs with zig zag stitching opens new avenues for creativity in textile production. Designers can incorporate various patterns and textures, appealing to a broader range of customers.

2. Increased Efficiency By significantly decreasing production time, these machines enable manufacturers to meet tight deadlines and adapt to changing market demands. The automation of stitching processes also minimizes the risk of human error.

3. Cost-Effective Production While the initial investment in industrial embroidery machines can be substantial, the long-term benefits often outweigh the costs. The efficiency and durability of these machines lead to lower operational costs in terms of labor and material waste.

4. Quality Assurance With precise stitching capabilities, zig zag embroidery machines ensure consistent quality across large production runs. This uniformity is crucial for branding and maintaining customer satisfaction.

Applications in the Textile Industry

Industrial zig zag embroidery machines play a significant role in various sectors of the textile industry. Some common applications include

- Apparel Manufacturing From shirts to outerwear, zig zag stitching is widely used in fashion for both decorative elements and functional seams. - Home Textiles Products such as curtains, bed linens, and upholstery benefit from the versatility and aesthetic quality of zig zag embroidery. - Sportswear and Activewear The durability of zig zag stitches makes them ideal for sports clothing, where elasticity and strength are paramount. - Promotional Products Custom embroidered items, such as caps and bags, often utilize zig zag stitching for logos and branding elements.

Conclusion

The industrial zig zag embroidery machine represents a significant advancement in textile manufacturing, offering unparalleled efficiency and creativity. As the industry continues to evolve, these machines will play a crucial role in meeting the growing demand for high-quality, innovative textile products. With their combination of speed, versatility, and precision, industrial zig zag embroidery machines are not just tools; they are essential partners in the art of modern embroidery.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025