Advanced Industrial Needle Feed Sewing Machines for Enhanced Fabric Handling and Seam Quality

The Industrial Needle Feed Sewing Machine A Game Changer in Textile Manufacturing

In the world of textile manufacturing, efficiency and precision are paramount. Among the various types of sewing machines available, the industrial needle feed sewing machine stands out as a pivotal invention that has revolutionized the industry. This machine, designed to meet the demands of high-volume production, offers a blend of speed, efficiency, and adaptability that is essential for modern textile operations.

Understanding Needle Feed Technology

At its core, the needle feed sewing machine operates on a unique mechanism that enhances the feeding of fabric through the machine. Unlike traditional feed dogs that pull the fabric from below, the needle feed mechanism moves the fabric in synchronization with the needle's movement. This harmony minimizes the risk of fabric shifting or bunching, which is particularly beneficial when working with slippery or layered materials.

This technology not only improves the quality of stitching but also allows for the seamless assembly of complex designs. This feature is crucial for heavy-duty applications such as upholstery, leather goods, and outdoor gear, where precise stitching is essential for durability and aesthetics.

Advantages of Industrial Needle Feed Sewing Machines

1. Enhanced Fabric Control The primary advantage of needle feed technology is its ability to provide better control over fabric feed. This feature is vital when sewing multiple layers of fabric, as it ensures that all layers are stitched evenly without distortion.

2. Reduced Material Waste Inconsistent fabric feeding often leads to misalignment and required adjustments, resulting in wasted material. The needle feed mechanism minimizes these issues, thereby reducing costs and maximizing material efficiency.

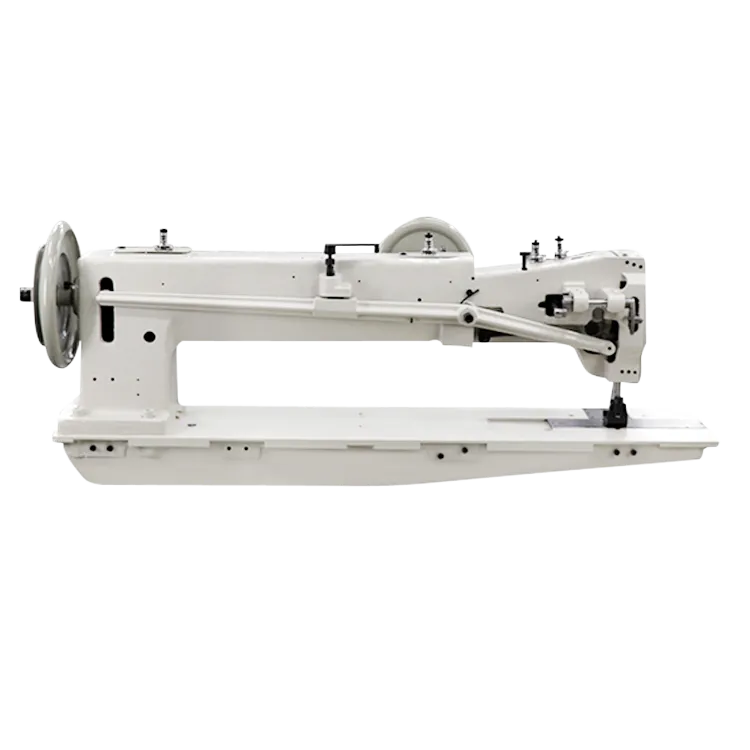

industrial needle feed sewing machine

3. Increased Speed and Productivity Industrial needle feed machines are built for speed. They can handle high-speed sewing operations, allowing manufacturers to increase output while maintaining quality. This is especially important in a competitive industry where time-to-market can significantly impact profitability.

4. Versatility in Applications These machines are highly versatile and can be used for various applications, from light fabrics like silk to heavy materials like canvas and leather. This adaptability makes them an ideal choice for companies that work with diverse textiles.

5. Low Maintenance Requirements Although these machines are designed for heavy-duty use, they typically require lower maintenance than their counterparts. This durability translates into less downtime for repairs, further enhancing overall productivity.

Applications in the Textile Industry

The industrial needle feed sewing machine is integral to several sectors within the textile industry. It is widely used in garment manufacturing, upholstery production, and the making of outdoor apparel and equipment. Companies that specialize in high-quality leather goods, such as handbags and footwear, also benefit from the precision offered by these machines.

Moreover, as sustainability becomes a more prominent focus within the manufacturing industry, the reduced material waste associated with needle feed technology aligns well with eco-friendly practices. Companies can achieve their production goals without compromising their commitment to sustainability.

Conclusion

In conclusion, the industrial needle feed sewing machine has become an indispensable tool in textile manufacturing. By improving fabric control, increasing productivity, and offering versatility across a range of materials, it represents a significant advancement in sewing technology. As the industry continues to evolve, innovations like the needle feed sewing machine will play a crucial role in shaping a more efficient and sustainable future for textile production. Whether you are a manufacturer seeking to improve production processes or someone passionate about advancements in sewing technology, the impact of needle feed machines is undeniably transformative.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025