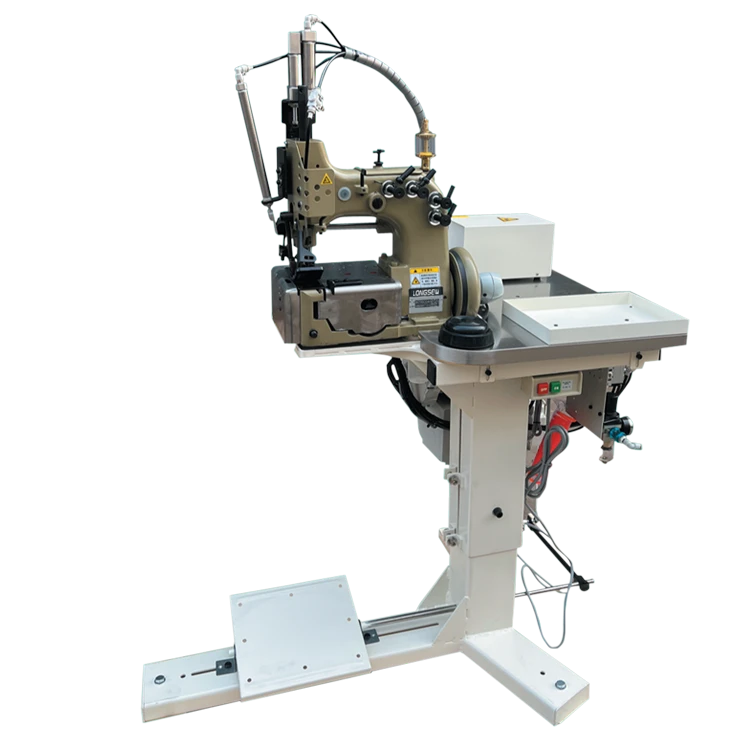

fibc sewing machine

The Importance of FIBC Sewing Machines in Modern Manufacturing

In today's fast-paced manufacturing landscape, efficiency and quality are paramount. Among the various tools and technologies that facilitate successful production processes, the FIBC (Flexible Intermediate Bulk Container) sewing machine stands out as an essential piece of equipment for companies that deal with bulk packaging. This article delves into the significance of FIBC sewing machines, their operational mechanisms, and their impact on the industry.

Understanding FIBC

FIBC containers, commonly referred to as bulk bags, have become a preferred choice for transporting and storing bulk products across a myriad of industries, including agricultural, chemical, and food sectors. Their advantages are plentiful they are lightweight, cost-effective, and reusable. FIBCs efficiently handle large volumes of materials, making them especially appealing in contexts where conventional packaging falls short.

The Role of FIBC Sewing Machines

FIBC sewing machines are specialized equipment designed for the sewing and finishing of bulk bags. These machines ensure that the bags are robust and durable, capable of withstanding the rigors of transportation and storage. The sewing process typically involves multiple layers of fabric, often made from materials such as polypropylene, which is known for its strength and resistance to moisture and chemicals.

The sewing technology behind these machines has evolved significantly, driven by the demand for higher productivity and reliability. Modern FIBC sewing machines offer various functionalities, including

1. Enhanced Speed and Efficiency With advancements in motor technology and automation, FIBC sewing machines can sew faster than traditional sewing equipment. This increased speed directly translates into higher output, making it an attractive investment for manufacturers looking to scale up production.

2. Precision and Quality Control Consistency in bag dimensions and seam quality is crucial for preventing spillage and ensuring product safety. FIBC sewing machines are equipped with advanced features such as automatic fabric tension adjustments and electronic control systems that enhance precision in the sewing process.

fibc sewing machine

3. Versatility These machines can be tailored to handle a variety of bag designs and sizes, accommodating the diverse needs of customers. Manufacturers can easily switch between producing different styles of FIBCs, ensuring flexibility in their production lines.

4. Durability and Maintenance Built to withstand heavy workloads, FIBC sewing machines are designed for longevity. Their components are crafted to minimize wear and tear, further enhancing the overall reliability of the sewing process. Additionally, many modern machines come with user-friendly interfaces that simplify maintenance procedures, reducing downtime.

The Environmental Aspect

As environmental concerns continue to rise, the packaging industry faces increasing pressure to adopt sustainable practices. FIBC bags are gaining popularity because they are reusable and recyclable, providing a greener alternative to single-use packaging. FIBC sewing machines support this trend by enabling the production of high-quality bags that can endure multiple trips. When manufacturers emphasize sustainable practices in their production processes, it not only addresses environmental issues but also appeals to eco-conscious consumers.

Economic Impacts

Investing in advanced FIBC sewing machines can lead to significant economic benefits. By improving production efficiency and reducing material waste, manufacturers can lower their overall operating costs. Moreover, with the increasing shift toward FIBC usage across various industries, companies that utilize these machines position themselves to capture a larger share of the market.

Conclusion

The FIBC sewing machine plays a critical role in modern manufacturing, particularly in the context of bulk packaging. Its versatility, efficiency, and reliability make it an indispensable tool for producers aiming to meet the growing demands of their customers while maintaining high-quality standards. As industries continue to evolve and focus on sustainability, the importance of such specialized equipment will only increase. Embracing the technology behind FIBC sewing machines not only enhances productivity but also contributes to a more sustainable future in packaging and manufacturing. In an era where efficiency and environmental responsibility go hand in hand, these machines are indeed paving the way for innovation and growth in the sector.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025