Efficient Techniques for Sewing FIBC Belts in Industrial Applications

Exploring FIBC Belt Sew A Deep Dive into Innovation and Efficiency

In the realm of bulk packaging, FIBC (Flexible Intermediate Bulk Container) bags have emerged as a revolutionary solution for transporting and storing a vast array of materials. One of the key aspects that enhance the durability and efficiency of these bags is the method of sewing used in their production, often referred to as FIBC belt sew. This specialized sewing technique is essential for ensuring that FIBC bags can withstand the rigors of heavy-duty use, which is vital in industries such as agriculture, construction, chemicals, and food processing.

Exploring FIBC Belt Sew A Deep Dive into Innovation and Efficiency

One of the significant advantages of FIBC belt sewing is its ability to form secure, reinforced seams that prevent leaking and spillage. This is particularly important in industries that deal with hazardous materials, where maintaining safety and compliance with regulations is paramount. Additionally, the reinforced seams contribute to the bags' overall lifespan, making them a cost-effective choice for businesses that rely on bulk packaging.

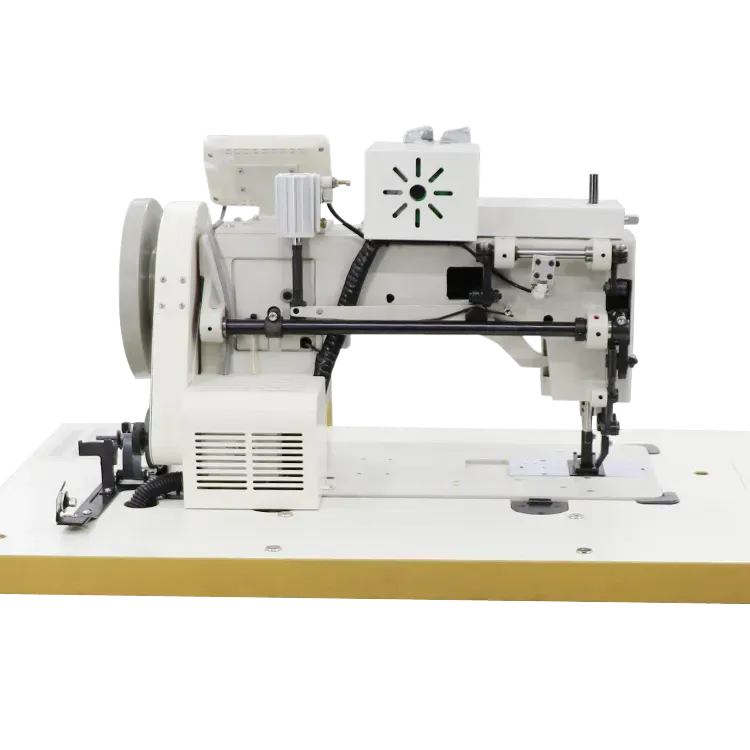

fibc belt sew

The process of FIBC belt sew also incorporates advancements in technology, including computerized sewing machines that ensure precision and consistency. These machines can operate at high speeds, increasing production efficiency while maintaining high-quality standards. Furthermore, manufacturers can customize the sewing patterns and types of seams, tailoring the bags to specific needs such as UV resistance or moisture-proofing.

As sustainability becomes a significant concern across industries, FIBC bags and their sewing methods are evolving. Many manufacturers are now focusing on using eco-friendly materials and threads, along with techniques that minimize waste during production. This shift not only aligns with global sustainability goals but also attracts environmentally conscious consumers.

In conclusion, FIBC belt sew is a pivotal component in the production of flexible bulk containers, intrinsically linked to their strength, reliability, and efficiency. As industries look for innovative packaging solutions, the advancements in FIBC sewing techniques pave the way for more durable and sustainable options. This not only enhances operational efficiency but also contributes to a safer and more environmentally friendly approach to bulk material handling. As the demand for FIBC bags grows, so too will the innovations in their manufacture, ensuring they remain an indispensable asset in various sectors.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025