Enhancing Proximity with Innovative Back Closer Technology for Improved Operational Efficiency

The Back Closer Machine Revolutionizing Manufacturing and Efficiency

In today's fast-paced manufacturing environment, the need for efficiency and precision has never been greater. As industries seek to optimize production processes, the introduction of specialized machinery plays a pivotal role. One such innovation is the back closer machine, a remarkable tool designed to enhance the closing process of various products, particularly in the textile, packaging, and assembly industries. This article delves into the functionality, advantages, and potential applications of the back closer machine, highlighting its importance in modern manufacturing.

Understanding the Back Closer Machine

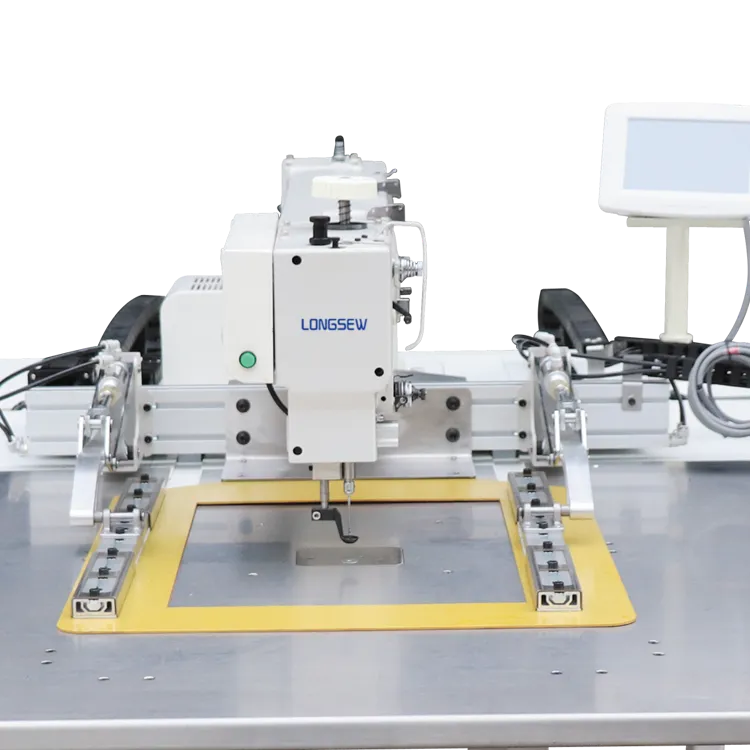

A back closer machine is an automated device primarily used for joining two or more components together to create a finished product. In the textile industry, for instance, this machine is employed to close the back seams of garments, such as shirts or pants, ensuring that the production process is both quicker and more consistent than manual methods. This machinery can handle various materials, including fabrics, plastics, and metals, adapting to the specific needs of the task at hand.

The operation of a back closer machine is relatively straightforward. The operator feeds the material into the machine, which then aligns the parts to be joined accurately. Using high-speed stitching or sealing mechanisms, the machine secures the components together while maintaining precision. This method not only reduces the likelihood of human error but also increases production speed, allowing manufacturers to meet high demand without sacrificing quality.

Advantages of the Back Closer Machine

One of the most significant benefits of using a back closer machine is the enhancement of efficiency. Traditional manual closing methods can be time-consuming and labor-intensive, resulting in bottlenecks in production lines. The automation provided by the back closer machine streamlines this process, enabling manufacturers to produce a higher volume of goods in a shorter period.

back closer machine

Additionally, the consistency achieved with a machine is unparalleled. Human operators can exhibit variability in skill level and technique, leading to inconsistent seams or closures. In contrast, the back closer machine performs the same operation with pinpoint accuracy across all products. This standardization not only improves product quality but also fosters customer satisfaction and brand loyalty.

Another notable advantage of the back closer machine is its adaptability. Many models can be programmed to perform various tasks, making them suitable for different industries and product types. This versatility allows businesses to invest in a single piece of equipment that can evolve with their production needs, ultimately saving time and resources.

Applications Across Industries

The applications of the back closer machine are diverse, spanning many sectors beyond textiles. In the packaging industry, these machines are used to seal boxes, bags, and containers efficiently. They ensure that products are securely packaged, reducing the risk of damage during transportation and storage.

In assembly lines, back closer machines can be employed to join components of electronic devices, furniture, and automotive parts. By maintaining high standards of precision and speed, manufacturers can enhance their operational workflows significantly.

Conclusion

The back closer machine represents a significant advancement in manufacturing technology. By automating the closing process, this innovative machinery enhances efficiency, improves product quality, and adapts to various applications across industries. As businesses continue to seek ways to streamline their operations and keep pace with market demands, investing in back closer machines presents a viable solution for achieving operational excellence. This machinery not only paves the way for increased output but also sets the stage for a future where manufacturing is synonymous with precision and efficiency.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025