فوریه . 10, 2025 10:27

Back to list

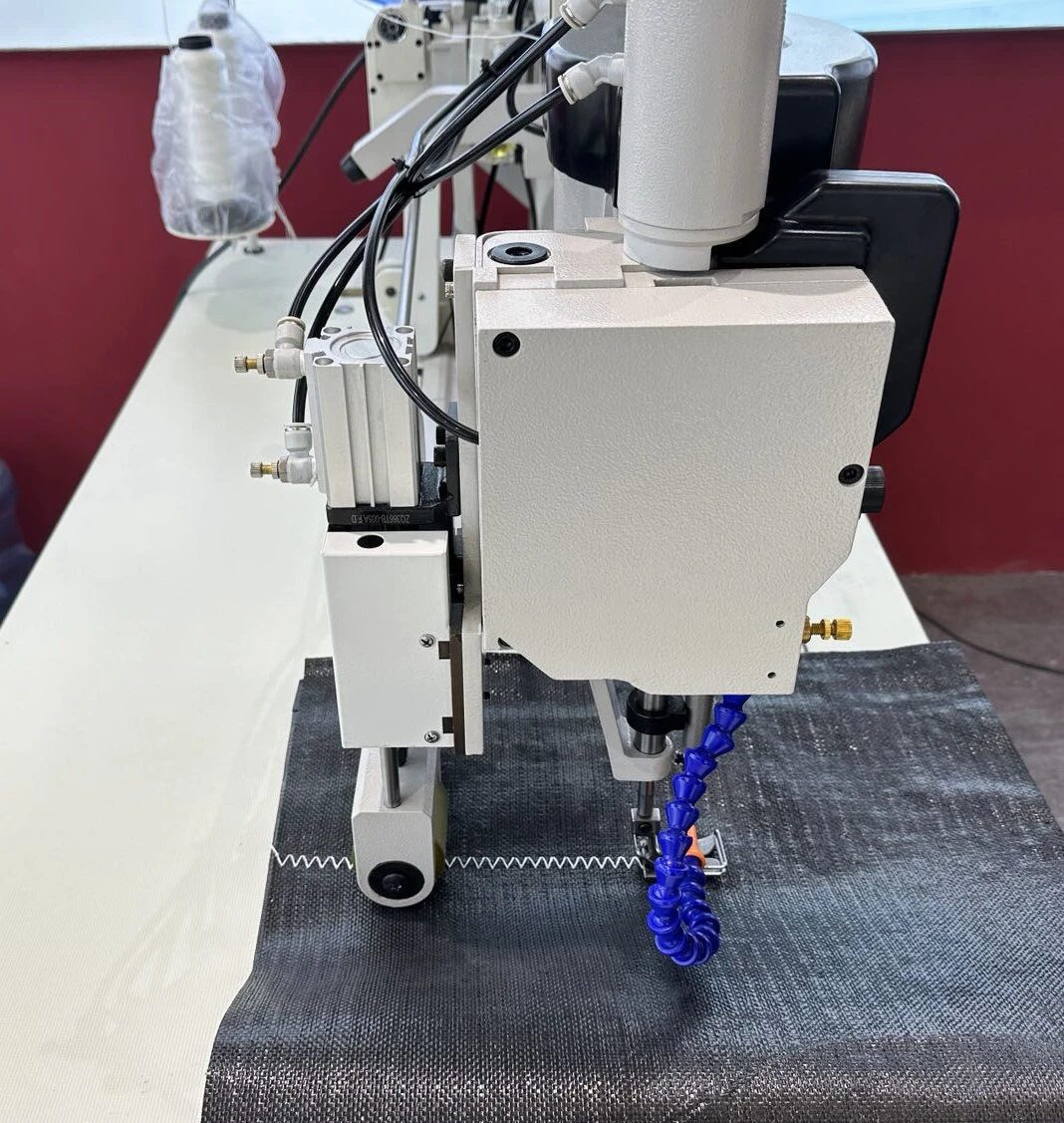

Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine For Like Boot Long Barrel Products GA411N

Cylindrical bed sewing machines stand as a hallmark of innovation and efficiency in the textile and leather manufacturing industries. For professionals seeking tools that blend cutting-edge functionality with durable performance, these machines offer an unparalleled solution. Designed specifically for tasks that involve tubular or circular stitching, cylindrical bed sewing machines cater to an array of industries from fashion to upholstery.

In terms of maintenance, cylindrical bed sewing machines are constructed with durable materials and are accompanied by an intuitive maintenance protocol. Regular oiling and cleaning routines are straightforward, complemented by accessible customer support and comprehensive manuals, which contribute to the machine's longevity and sustained peak performance. The integration of digital interfaces has further revolutionized these machines. With programmable stitching patterns and real-time diagnostics, the ease of tracking production efficiency and identifying potential issues before they escalate has become a vital component of the manufacturing process. These technological advancements not only improve operational efficiency but also uphold the quality control standards demanded by modern manufacturing industries. As the market grows increasingly competitive, investing in a cylindrical bed sewing machine is more than just a purchase—it's a strategic investment in precision, efficiency, and innovation. For businesses, this means improved turnaround times, reduced error rates, and enhanced product quality, which collectively foster customer loyalty and open doors to new market opportunities. Thus, for artisans and large-scale manufacturers alike, the cylindrical bed sewing machine emerges not merely as a tool, but as a crucial partner in achieving excellence in crafting well-made and durable items. By incorporating this machine into your production line, you are not only improving your operational capabilities but also ensuring that your products can hold their ground in an ever-evolving industry landscape. Conclusively, the cylindrical bed sewing machine showcases the intersection of traditional craftsmanship and technological advancement. Its contribution to the textile and leather industries is indispensable, aligning with the experience, expertise, authoritativeness, and trustworthiness that modern businesses demand. Investing in such a machine promises not only to enhance production quality but also signifies a commitment to maintaining the impeccable standards that customers expect today.

In terms of maintenance, cylindrical bed sewing machines are constructed with durable materials and are accompanied by an intuitive maintenance protocol. Regular oiling and cleaning routines are straightforward, complemented by accessible customer support and comprehensive manuals, which contribute to the machine's longevity and sustained peak performance. The integration of digital interfaces has further revolutionized these machines. With programmable stitching patterns and real-time diagnostics, the ease of tracking production efficiency and identifying potential issues before they escalate has become a vital component of the manufacturing process. These technological advancements not only improve operational efficiency but also uphold the quality control standards demanded by modern manufacturing industries. As the market grows increasingly competitive, investing in a cylindrical bed sewing machine is more than just a purchase—it's a strategic investment in precision, efficiency, and innovation. For businesses, this means improved turnaround times, reduced error rates, and enhanced product quality, which collectively foster customer loyalty and open doors to new market opportunities. Thus, for artisans and large-scale manufacturers alike, the cylindrical bed sewing machine emerges not merely as a tool, but as a crucial partner in achieving excellence in crafting well-made and durable items. By incorporating this machine into your production line, you are not only improving your operational capabilities but also ensuring that your products can hold their ground in an ever-evolving industry landscape. Conclusively, the cylindrical bed sewing machine showcases the intersection of traditional craftsmanship and technological advancement. Its contribution to the textile and leather industries is indispensable, aligning with the experience, expertise, authoritativeness, and trustworthiness that modern businesses demand. Investing in such a machine promises not only to enhance production quality but also signifies a commitment to maintaining the impeccable standards that customers expect today.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025