Heavy-Duty Container Bag Sewing Machine Portable & Affordable Prices

- Overview of Container Bag Sewing Machine Innovations

- Technical Advantages in Modern Stitching Systems

- Manufacturer Comparison: Performance and Reliability

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications Across Industries

- Cost Efficiency and Maintenance Insights

- Future Developments in Bag Closing Technology

(container bag sewing machine)

Innovations in Container Bag Sewing Machine Technology

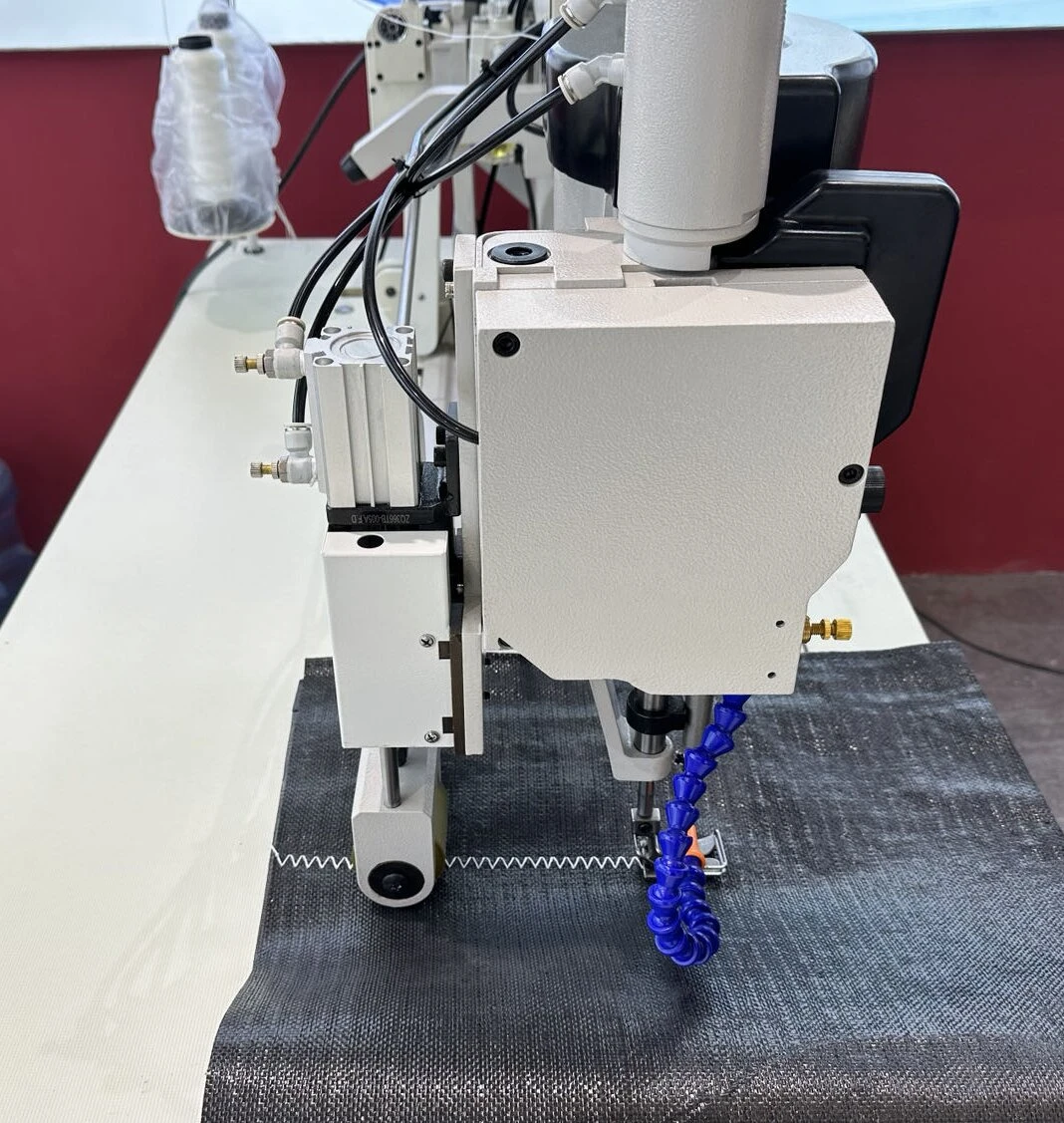

The container bag sewing machine

has revolutionized bulk packaging, offering precision and durability for FIBCs (Flexible Intermediate Bulk Containers). Unlike traditional methods, modern machines integrate automated thread tension control and high-speed stitching, reducing production time by up to 30%. Manufacturers now prioritize energy efficiency, with some models consuming 15% less power while maintaining 1,500 stitches per minute. This evolution addresses critical demands in agriculture, construction, and chemicals, where seam strength directly impacts safety.

Technical Advantages in Modern Stitching Systems

Advanced lockstitch mechanisms ensure leak-proof seams for hazardous materials. For instance, the FIBC bag lockstitch sewing machine employs dual-needle technology, achieving tensile strengths exceeding 50 N/mm². Key features include:

- Programmable stitch patterns (e.g., double-lock, chainstitch)

- Real-time error detection via IoT sensors

- Compatibility with UV-resistant and anti-static threads

Manufacturer Comparison: Performance and Reliability

| Brand | Model | Speed (stitches/min) | Max Material Thickness (mm) | Price Range (USD) |

|---|---|---|---|---|

| AlphaStitch | AS-4500 | 1,800 | 8 | 12,000–15,000 |

| BulkMaster | BM-L9 | 1,200 | 10 | 9,500–11,500 |

| SturdyPack | SP-360 | 2,200 | 6 | 14,200–17,000 |

Custom Solutions for Diverse Industrial Needs

Tailored configurations address niche requirements, such as portable bag closer sewing machines for on-site repairs. A leading supplier recently engineered a waterproof variant for marine cargo applications, utilizing corrosion-resistant alloys. Customization options typically include:

- Adjustable conveyor widths (500–2,000 mm)

- Hybrid pneumatic-electric drive systems

- Compliance with ATEX standards for explosive environments

Real-World Applications Across Industries

In the chemical sector, a European manufacturer reported a 40% reduction in bag failures after switching to automated container bag sewing machines. Similarly, agricultural cooperatives utilize portable units to seal 1-ton grain sacks directly in fields, minimizing handling costs. Case studies highlight:

- 25% faster turnaround in pharmaceutical powder packaging

- Zero downtime in 24/7 cement bagging lines

Cost Efficiency and Maintenance Insights

While the portable bag closer sewing machine price varies between $7,000 and $20,000, ROI is achievable within 8–14 months through labor savings. Preventive maintenance schedules extend machine lifespan by 3–5 years. Critical practices include:

- Monthly lubrication of needle bar assemblies

- Bi-annual motor calibration

- Immediate replacement of worn feed dogs

Future Trends in Container Bag Sewing Solutions

Emerging AI-driven models predict thread breakage with 98% accuracy, while solar-powered FIBC bag lockstitch sewing machines gain traction in off-grid facilities. Industry 4.0 integration enables remote diagnostics, cutting service response times by 70%. As sustainability pressures mount, recyclable thread alternatives and carbon-neutral production methods will dominate R&D pipelines.

(container bag sewing machine)

FAQS on container bag sewing machine

Q: What are the key features of a container bag sewing machine?

A: Container bag sewing machines are designed for heavy-duty stitching, offering high-speed performance and durability. They handle thick materials like polypropylene and provide consistent seam quality for FIBC bags. Industrial-grade motors ensure long-term reliability.

Q: How does a FIBC bag lockstitch sewing machine improve stitching durability?

A: FIBC bag lockstitch machines use a tight, interlocking stitch pattern to prevent unraveling under stress. This ensures seams withstand heavy loads and rough handling. The lockstitch mechanism also enhances resistance to abrasion and tearing.

Q: What factors affect the price of a portable bag closer sewing machine?

A: Pricing depends on motor power, portability features, and stitch customization options. Brands with advanced automation or ergonomic designs may cost more. Maintenance requirements and warranty coverage also influence the final price.

Q: Can a container bag sewing machine handle multiple fabric layers?

A: Yes, these machines are built to sew through 4-8 layers of thick woven materials. Heavy-duty needles and reinforced feed systems ensure smooth stitching. Adjustable presser foot pressure accommodates varying fabric thicknesses.

Q: Is a portable bag closer sewing machine suitable for on-site repairs?

A: Absolutely. Portable models are lightweight, compact, and often battery-powered for field use. They enable quick repairs of FIBC bags at warehouses or construction sites. Their simplicity ensures minimal setup time and easy operation.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025