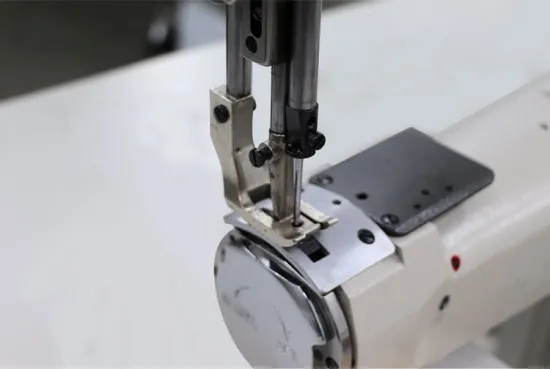

car seat cover stitching machine

The Importance of Stitching Machines in Car Seat Cover Production

In the automotive industry, aesthetics and durability play crucial roles in the appeal of vehicle interiors. Among the various components that contribute to this appeal, car seat covers are particularly significant. Transforming the look of a vehicle while providing a layer of protection to seats, seat covers are both functional and stylish. One key element in their production is the stitching machine, which ensures quality, precision, and efficiency.

The Importance of Stitching Machines in Car Seat Cover Production

One of the primary benefits of using advanced stitching machines is the consistency they provide. In mass production, maintaining a uniform quality across a large number of products is critical. Automated stitching machines ensure that every seam is identical, which is vital for large-scale manufacturing. This consistency not only enhances the aesthetic appeal of the seat covers but also reinforces their durability, preventing premature wear.

car seat cover stitching machine

Furthermore, modern stitching machines come equipped with programmable features that allow manufacturers to create intricate designs and patterns. Customization is a growing trend in the automotive market, and the ability to produce unique seat cover designs can set a company apart from its competitors. Whether it's a simple logo or a complex floral pattern, advanced stitching technology can deliver the desired results with precision.

Another advantage of using stitching machines in car seat cover production is efficiency. Automated systems can significantly reduce production time, enabling manufacturers to meet rising consumer demands. This increased speed does not compromise quality; rather, it amplifies productivity. As a result, companies can reduce costs, improve profit margins, and respond quickly to market trends.

Additionally, with sustainability becoming increasingly paramount in the automotive industry, modern stitching machines can help minimize waste. By ensuring precise cuts and stitches, these machines reduce material consumption and decrease the likelihood of defects, leading to more eco-friendly manufacturing practices.

In conclusion, the role of stitching machines in the production of car seat covers is pivotal. They not only enhance the quality and durability of the products but also facilitate customization and improve production efficiency. As the automotive industry continues to evolve, investing in advanced stitching technology will undoubtedly contribute to better aesthetics, functionality, and sustainability in vehicle interiors. The future of car seat covers is bright, driven by innovation and the capabilities of modern stitching machines.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025