Improving Efficiency with Back Closer Machinery for Enhanced Operations

Understanding the Back Closer Machine Revolutionizing Manufacturing Efficiency

In the ever-evolving landscape of manufacturing and production, innovation plays a crucial role in ensuring efficiency, flexibility, and speed. Among the notable advancements in this sector is the Back Closer Machine, a pivotal piece of equipment that has significantly transformed how businesses approach their operations.

What is a Back Closer Machine?

The Back Closer Machine is a specialized device designed for the closing and sealing of products, primarily in the packaging industry. It automates the process of sealing the backs of pouches, bags, or boxes, ensuring that products remain safe and secure during transportation and storage. The machine's design focuses on high-speed operation while maintaining accuracy, making it an invaluable asset for manufacturers aiming to improve productivity.

Key Features

One of the standout features of the Back Closer Machine is its versatility. It can be configured to handle various types of materials and seal styles, accommodating different products ranging from food items to pharmaceuticals. This adaptability is essential for manufacturers who produce a wide array of products and need equipment that can meet diverse requirements.

Moreover, the Back Closer Machine often comes equipped with advanced technology, including sensors and automated controls. These features allow real-time monitoring and adjustment during the sealing process, reducing the likelihood of errors and ensuring a consistent seal quality. This level of precision not only enhances product integrity but also enhances consumer confidence in the product’s safety and reliability.

Benefits to Manufacturers

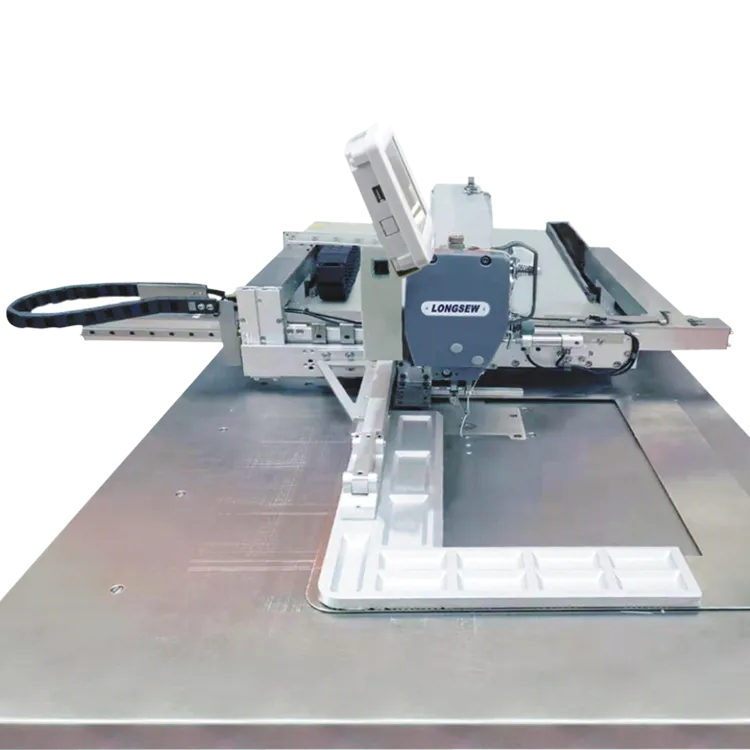

back closer machine

The implementation of a Back Closer Machine in a production line offers a multitude of advantages. Firstly, it significantly reduces the time taken to complete the sealing process. Manual sealing can be tedious and time-consuming, especially when dealing with high volumes of product. However, with an automated Back Closer Machine, manufacturers can achieve higher output rates, thus meeting market demands more efficiently.

Secondly, this machine minimizes labor costs. With automation taking over the sealing process, the need for manual labor is diminished, allowing staff to focus on other important tasks that require human oversight and creativity. This leads to not only cost savings but also improved employee satisfaction, as workers are engaged in more meaningful roles within the company.

Furthermore, the Back Closer Machine contributes to waste reduction. A well-sealed product is less likely to be damaged during transportation, which can result in significant savings for manufacturers. Moreover, by ensuring that packaging is performed accurately and efficiently, businesses can avoid the costs associated with product recalls and unsatisfied customers.

The Future of Packaging with Back Closer Machines

As the demand for efficient and reliable packaging solutions continues to grow, the Back Closer Machine stands at the forefront of innovations in this field. Manufacturers are increasingly recognizing the importance of investing in machinery that not only meets their current needs but is also adaptable to future trends.

One of the foreseeable trends includes the integration of smart technology. Back Closer Machines are likely to incorporate Internet of Things (IoT) capabilities, allowing for remote monitoring and maintenance. This will enable manufacturers to preemptively address any issues that may arise, thus minimizing downtime and ensuring seamless operations.

Conclusion

In conclusion, the Back Closer Machine is more than just an equipment upgrade; it represents a significant leap toward enhancing operational efficiency in manufacturing. Its ability to automate the sealing process not only speeds up production but also leads to cost savings and improved product quality. As more companies strive to stay competitive in a fast-paced market, embracing such technologies will undoubtedly be key to their success. With the integration of advanced technology and the trend towards smart manufacturing, the Back Closer Machine is poised to play a vital role in the future of the packaging industry.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025