Industrial Automatic Sewing Machines for Efficient and Precise Fabric Production Solutions

The Evolution and Impact of Industrial Automatic Sewing Machines

The evolution of the textile and apparel industry has been significantly influenced by technological advancements, particularly in sewing machinery. Among these, automatic sewing machines have emerged as the backbone of industrial textile production, revolutionizing the way garments are manufactured. This article delves into the journey of automatic sewing machines, their benefits, and their impact on the fashion industry.

Historical Overview

The sewing machine was invented in the 19th century, drastically changing the garment industry. However, it wasn't until the introduction of automatic sewing machines in the mid-20th century that the industry experienced a paradigm shift. Unlike traditional machines, which required manual operation, automatic sewing machines were designed to automate specific tasks, thereby increasing productivity and efficiency.

The initial focus was on straight stitching, but as technology advanced, machines began incorporating various functions such as embroidery, hemming, and buttonholing. Today’s automatic sewing machines can handle multiple tasks within a single operation, reflecting the sophisticated demands of modern garment production.

Advantages of Automatic Sewing Machines

Automatic sewing machines offer numerous advantages that make them indispensable in the industrial sector. Firstly, they enhance productivity. These machines can run for longer periods with minimal supervision, vastly increasing output compared to manual sewing methods. This efficiency is crucial in meeting the fast-paced demands of the fashion industry, where time-to-market can determine a brand's success.

Secondly, automatic machines improve consistency and quality. Human error is an inevitable factor in manual sewing, leading to variations in stitching quality. Automatic machines, equipped with precision engineering and electronic controls, produce consistent results, ensuring that each garment meets predetermined quality standards. This uniformity is essential for brands that emphasize quality in their products.

Moreover, these machines have a positive impact on labor conditions. By automating repetitive and physically demanding tasks, they help reduce the physical strain on workers. This, in turn, allows factories to employ workers in more skilled roles, focusing on quality control and machine maintenance, which can lead to better job satisfaction and skill development.

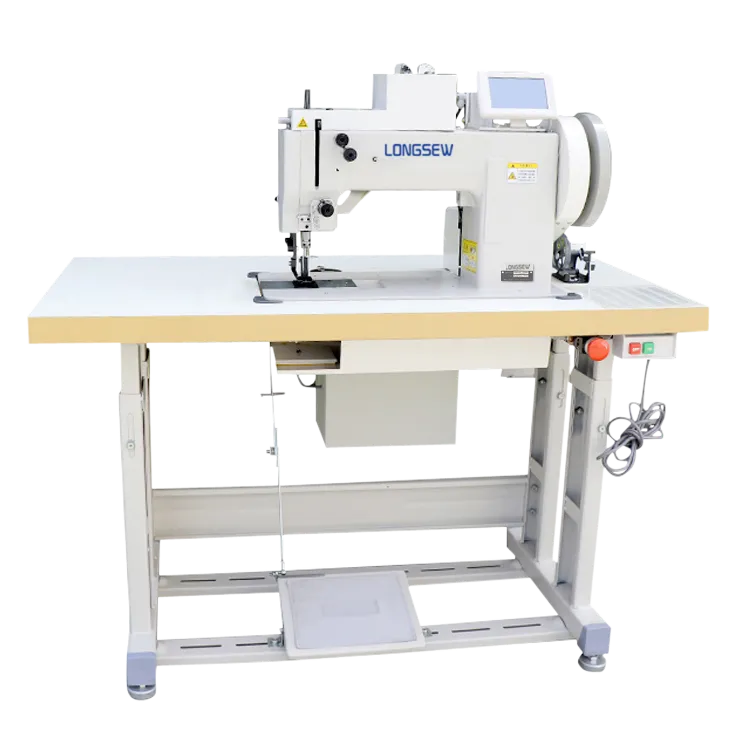

automatic sewing machine industrial

Technological Innovations

Recent technological innovations have further enhanced the capabilities of automatic sewing machines. The integration of computer technology has led to the development of programmable machines that can be easily tailored to different sewing tasks. For example, advanced software allows operators to design patterns and control the machine settings remotely, optimizing the workflow.

Additionally, the advent of artificial intelligence (AI) in automatic sewing machines is paving the way for even greater efficiencies. AI can analyze fabric behavior and adjust sewing parameters in real-time, helping to prevent issues such as fabric puckering and distortion. This not only increases productivity but also enhances the final product’s quality.

Challenges Facing the Industry

Despite their numerous advantages, the adoption of automatic sewing machines is not without its challenges. The initial investment cost can be significant, posing a barrier for smaller manufacturers. Additionally, as technology advances, there is a growing need for skilled technicians who can operate and maintain these machines, leading to a skills gap in some regions.

Furthermore, the rise of automation raises concerns about job displacement. While some jobs become obsolete, new roles are created in machine operation and maintenance. It is essential for the industry to address these concerns through training and reskilling programs, ensuring that workers are equipped for the evolving market demands.

Conclusion

Automatic sewing machines have transformed the garment industry, driving productivity, consistency, and quality. As technology continues to evolve, these machines will play an increasingly pivotal role in shaping the future of apparel manufacturing. Embracing the challenges and opportunities presented by these advancements will be crucial for manufacturers to remain competitive in an ever-changing global market. The journey of automatic sewing machines is a testament to the power of innovation in driving efficiency and enhancing the capabilities of the textile industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025