فوریه . 04, 2025 05:45

Back to list

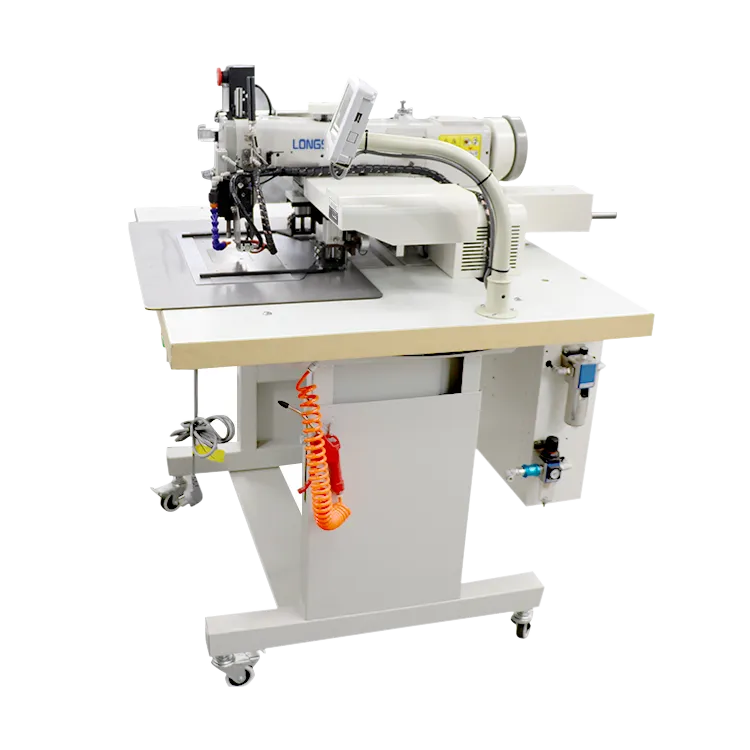

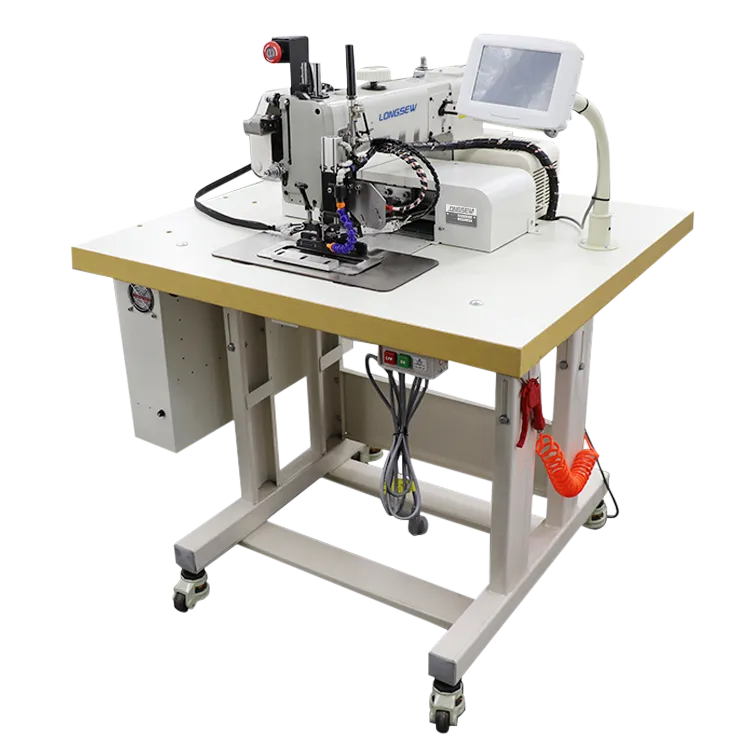

Heavy Duty Computerized Auto Pattern Sewing Machine For Safety Rope or Safety Belt LS273-2010H / LS273-2010S

Automatic sewing machines have revolutionized the textile industry, especially within factory settings, where efficiency, speed, and precision are paramount. These machines are designed to enhance productivity while maintaining high-quality standards, thus proving to be an invaluable asset for large-scale production facilities. When deciding to integrate automatic sewing machines into a factory, several key factors underscore their importance, efficacy, and reliability.

Trustworthiness is a crucial consideration for factory operators seeking to adopt automatic sewing machines. Reliable after-sales support is essential to maintaining operational continuity. Leading manufacturers offer comprehensive service packages, including installation, training, and maintenance support, contributing to a seamless integration process. The availability of genuine spare parts and accredited technicians ensures factories can rely on these machines for long-term productivity. Moreover, automatic sewing machines enhance sustainability efforts by minimizing fabric waste and reducing energy consumption. Programmable options allow precise material usage, thereby optimizing resource allocation and reducing the environmental footprint. Many manufacturers prioritize eco-friendly practices, incorporating energy-efficient technologies in their machine designs, thus aligning with global sustainability goals. When contemplating the acquisition of automatic sewing machines for a factory setting, it's essential to conduct thorough research and assess individual operational requirements. Factors such as production volume, fabric types, and desired automation level should guide the selection process. Engaging with industry experts and consulting existing users can provide valuable insights and practical experiences, further informing decision-making and ensuring the chosen solution aligns with the factory's strategic goals. In conclusion, the incorporation of automatic sewing machines within factory environments signifies a strategic investment in technology that fosters enhanced productivity, quality control, and operational efficiency. Their adoption reflects a broader trend of embracing automation to meet the ever-evolving demands of the global textile industry. By focusing on factors such as efficiency, expertise, authoritativeness, and trustworthiness, factory operators can ensure a successful integration that yields tangible benefits in both the short and long term.

Trustworthiness is a crucial consideration for factory operators seeking to adopt automatic sewing machines. Reliable after-sales support is essential to maintaining operational continuity. Leading manufacturers offer comprehensive service packages, including installation, training, and maintenance support, contributing to a seamless integration process. The availability of genuine spare parts and accredited technicians ensures factories can rely on these machines for long-term productivity. Moreover, automatic sewing machines enhance sustainability efforts by minimizing fabric waste and reducing energy consumption. Programmable options allow precise material usage, thereby optimizing resource allocation and reducing the environmental footprint. Many manufacturers prioritize eco-friendly practices, incorporating energy-efficient technologies in their machine designs, thus aligning with global sustainability goals. When contemplating the acquisition of automatic sewing machines for a factory setting, it's essential to conduct thorough research and assess individual operational requirements. Factors such as production volume, fabric types, and desired automation level should guide the selection process. Engaging with industry experts and consulting existing users can provide valuable insights and practical experiences, further informing decision-making and ensuring the chosen solution aligns with the factory's strategic goals. In conclusion, the incorporation of automatic sewing machines within factory environments signifies a strategic investment in technology that fosters enhanced productivity, quality control, and operational efficiency. Their adoption reflects a broader trend of embracing automation to meet the ever-evolving demands of the global textile industry. By focusing on factors such as efficiency, expertise, authoritativeness, and trustworthiness, factory operators can ensure a successful integration that yields tangible benefits in both the short and long term.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025