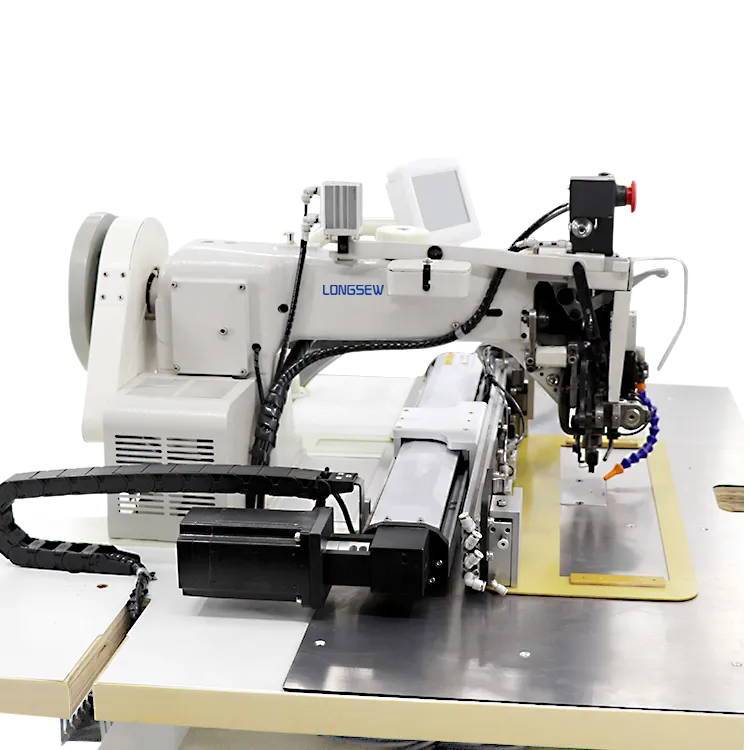

automatic bag closer sewing machine

The Efficiency of Automatic Bag Closer Sewing Machines

In the modern world of manufacturing and packaging, efficiency and precision are paramount

. Among the myriad of machinery that facilitates these processes, the automatic bag closer sewing machine stands out as a crucial tool for businesses handling packaging tasks. This innovative machine offers a combination of speed, reliability, and consistent quality, enabling companies to enhance their production capabilities significantly.Automatic bag closer sewing machines are designed to streamline the bag closure process, which is essential in industries such as food processing, agriculture, and construction. Traditional methods of closing bags, such as manual sewing or tying, can lead to inconsistencies and require extensive labor, which is both time-consuming and costly. In contrast, automatic bag closers provide a fast, uniform, and secure method of sealing bags, ultimately reducing labor costs and increasing throughput.

These machines operate using advanced technology, typically featuring programmable settings that allow users to customize the sewing pattern, thread tension, and speed according to their specific needs. This flexibility makes them suitable for a wide range of bag types and materials, from light plastic to heavy-duty woven fabrics. The ability to work with various materials ensures that businesses can adapt to changing demands and optimize their production processes.

automatic bag closer sewing machine

One of the key advantages of using these machines is their reliability. Automatic bag closer sewing machines are built to withstand the rigors of continuous operation. They are equipped with powerful motors that enable them to perform efficiently over long periods without the need for frequent maintenance. This reliability not only improves productivity but also reduces the likelihood of errors that can occur with manual sewing practices, such as uneven stitches or missed closures.

Moreover, these machines contribute significantly to workplace safety. By automating the bag closing process, businesses can minimize the potential for workplace injuries that may arise from repetitive manual tasks. Employees can be reassigned to more strategic roles that require critical thinking and oversight rather than tedious manual labor, thus enhancing job satisfaction and productivity.

In addition to efficiency and safety, automatic bag closer sewing machines also play a vital role in maintaining product quality. A tightly sealed bag ensures that its contents remain fresh and protected from contaminants, which is crucial in the food industry. Furthermore, a well-closed bag enhances the brand's image by presenting a professional appearance that can attract more customers.

To sum up, the adoption of automatic bag closer sewing machines is a game-changer for industries that rely on packaging. By improving speed, ensuring quality, and enhancing safety, these machines transform the way businesses operate, allowing them to meet consumer demands effectively. As technology continues to evolve, the capabilities and efficiencies of these machines are likely to advance even further, solidifying their place as indispensable tools in the manufacturing and packaging sectors. Investing in such machinery not only paves the way for streamlined operations but also contributes to a strong competitive edge in an ever-evolving marketplace.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025