Sewing Machines for Woven Sack Bag Production and Customization

The Importance of Woven Sack Bag Sewing Machines in Modern Manufacturing

In the realm of manufacturing, the efficiency and quality of production play crucial roles in determining the success of a business. One sector that has seen significant growth is the woven sack bag industry. Woven sacks, known for their durability and versatility, are commonly used for packaging a wide range of products, from agricultural goods to construction materials. This rise in demand has led to a corresponding increase in the importance of specialized machinery, particularly woven sack bag sewing machines.

Woven sack bag sewing machines are specifically designed to create strong and reliable seams in woven polypropylene (PP) or high-density polyethylene (HDPE) sacks. These materials are preferred for their lightweight yet sturdy characteristics, making them ideal for heavy-duty packaging. The sewing process ensures that the bags can endure the rigors of storage and transportation, providing manufacturers with a dependable solution for their packaging needs.

One of the key features of woven sack bag sewing machines is their ability to handle a variety of materials. These machines can stitch sacks made from different types of woven fabrics, allowing manufacturers to cater to an array of market demands. Whether the requirement is for larger bags used in bulk packaging or smaller sacks for retail items, these sewing machines can be adjusted to accommodate numerous formats and sizes. This versatility not only streamlines the production process but also reduces the need for multiple machines, saving both space and costs in the manufacturing facility.

Moreover, modern woven sack bag sewing machines come equipped with advanced technology that enhances efficiency and accuracy. Automated functions, such as speed control and stitch length adjustment, allow operators to produce consistent seams while minimizing material wastage. Some machines are even fitted with computerized systems that enable quick changes in production settings, catering to different client specifications without lengthy downtime. This increased level of automation ensures that manufacturers can keep pace with the high demand for woven sacks in today's fast-paced market.

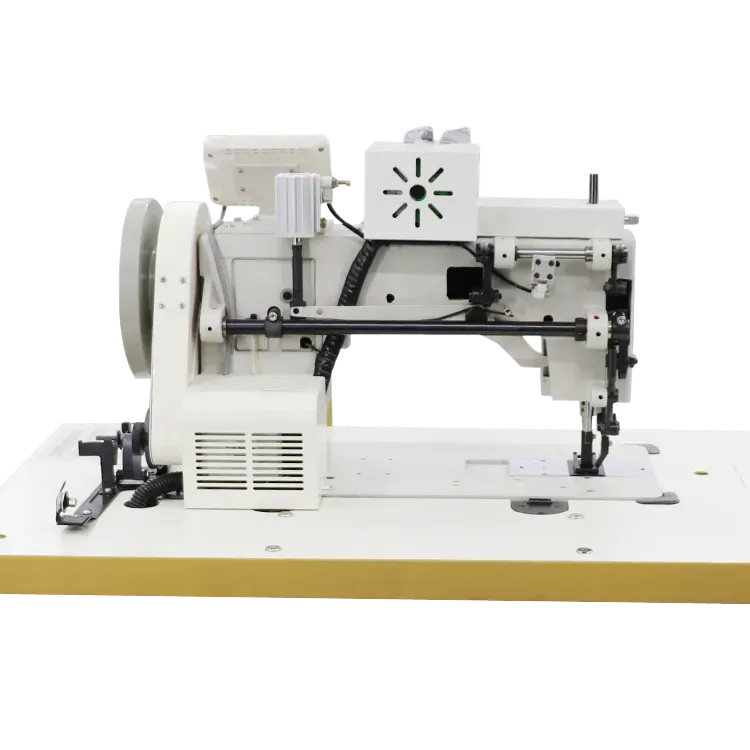

woven sack bag sewing machine

Quality control is another critical aspect where woven sack bag sewing machines excel. These machines are designed to create robust seams that withstand stress during filling and transport, ensuring that the contents remain secure. In an industry where product integrity is paramount, the ability to produce high-quality sewn sacks can distinguish a manufacturer from its competitors. By investing in reliable sewing technology, businesses can enhance their reputation and customer satisfaction, driving repeat sales and fostering brand loyalty.

In addition to improving productivity and quality, woven sack bag sewing machines contribute to sustainability efforts within the industry. As the demand for eco-friendly packaging rises, manufacturers are increasingly opting for biodegradable or recyclable materials. Woven sack production generates less waste compared to traditional packaging methods, and efficient sewing machines help optimize this process. By utilizing machines that minimize fabric waste and maximize energy efficiency, manufacturers can align their production practices with environmentally-friendly initiatives.

Furthermore, skilled operators who understand the intricacies of operating these machines are vital to the success of production lines. Training employees on the correct use and maintenance of woven sack bag sewing machines not only extends the lifespan of the equipment but also ensures high-quality output. Investing in personnel development can enhance operational efficiency and overall workplace morale, fostering a culture of continuous improvement.

In conclusion, woven sack bag sewing machines are an indispensable asset in the manufacturing landscape. Their ability to produce strong, reliable, and versatile bags is crucial for meeting the diverse packaging needs of various industries. With advancements in technology, quality control, and a focus on sustainability, these machines play a pivotal role in driving the success of woven sack manufacturers. As the global demand for woven sacks continues to grow, investing in efficient sewing machinery will be key to staying competitive in an ever-evolving marketplace.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025