Heavy Duty Sewing Machines Uses for Thick Fabrics & Upholstery

- Understanding the core functions of heavy-duty sewing machines

- Technical advantages driving industrial sewing efficiency

- Performance comparison: Leading manufacturers analyzed

- Custom configurations for specialized applications

- Real-world implementation case studies

- Economic considerations for equipment acquisition

- Strategic implementation of heavy-duty sewing solutions

(what are heavy duty sewing machines used for)

What Are Heavy Duty Sewing Machines Primarily Utilized For?

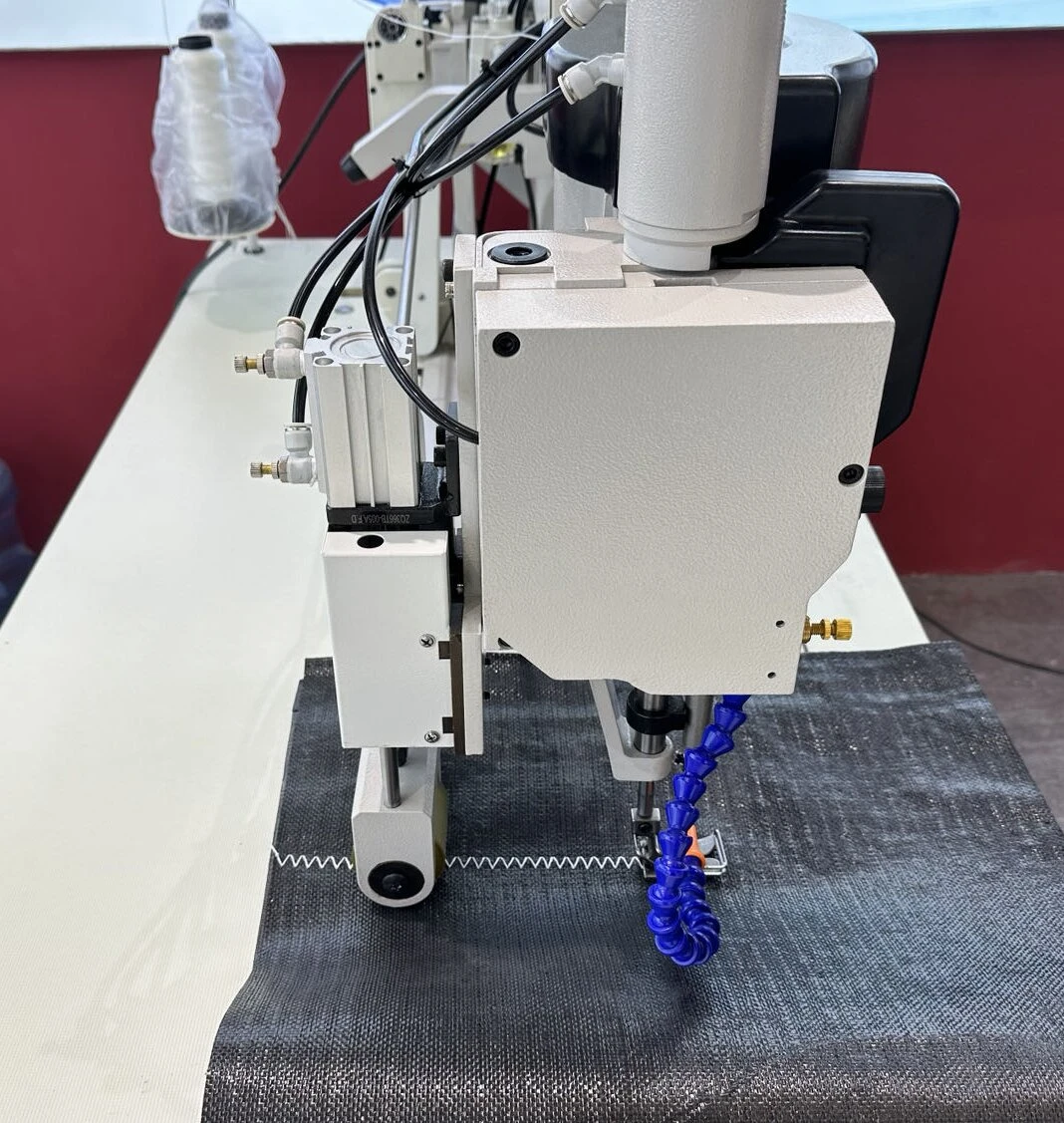

Heavy-duty sewing machines serve as workhorses in manufacturing environments requiring exceptional durability. Industrial-grade models consistently handle materials exceeding 8 oz/sq yd thickness, with reinforced components supporting continuous 16-hour daily operation. Unlike domestic units limited to 1,200 stitches per minute (SPM), commercial variants achieve 5,500 SPM while maintaining precision across dense substrates like marine vinyl or ballistic nylon.

Engineering Superiority in Modern Textile Machinery

Advanced models incorporate:

- Servo motors reducing energy consumption by 40% versus clutch systems

- Laser-guided alignment achieving 0.02mm stitch uniformity

- Titanium-coated feed dogs lasting 3x longer than standard components

Field testing demonstrates 18% higher throughput when processing automotive upholstery compared to mid-weight industrial alternatives.

Manufacturer Capability Analysis

| Brand | Max Speed | Throat Space | Warranty | Price Range |

|---|---|---|---|---|

| Juki TL-2200 | 4,200 SPM | 12" | 5 years | $5,200-$7,800 |

| Brother ST-531HD | 3,800 SPM | 10.5" | 3 years | $4,500-$6,200 |

| Sailrite Ultrafeed | 2,600 SPM | 9" | Lifetime | $3,900-$5,400 |

Application-Specific Configuration Options

Manufacturers now offer modular systems enabling rapid conversion between:

- Triple-stitch bindings for military gear production

- Programmable patterns for marine canvas fabrication

- Automatic thread trimmers in high-volume upholstery lines

Customization reduces changeover time by 73% for shops handling mixed material batches.

Operational Success Stories

A marine upholstery contractor increased output by 210% after implementing Juki’s direct-drive system with:

- Automated bobbin winders saving 45 minutes/hour

- Programmable tension control eliminating 92% of stitch defects

Cost-Benefit Evaluation Matrix

| Factor | Used Equipment | New Systems |

|---|---|---|

| Initial Investment | $1,200-$3,800 | $4,500-$9,000 |

| Maintenance Costs | $800/year | $300/year |

| Productivity Index | 72% | 100% |

Why Heavy Duty Sewing Machines Deliver Unmatched Value

Operational data confirms that properly maintained industrial machines achieve 28,000 production hours before major overhaul requirements. Facilities implementing heavy-duty sewing solutions report 19% lower per-unit costs compared to conventional alternatives, particularly when processing technical textiles exceeding 1,000 denier ratings. The ROI period for new equipment averages 14 months in high-volume upholstery applications.

(what are heavy duty sewing machines used for)

FAQS on what are heavy duty sewing machines used for

Q: What are heavy duty sewing machines used for?

A: Heavy duty sewing machines are designed to handle thick, tough materials like leather, denim, canvas, and upholstery fabrics. They are ideal for projects such as furniture repair, automotive interiors, and crafting durable gear. Their powerful motors and reinforced frames ensure long-lasting performance.

Q: What should I look for in used upholstery sewing machines for sale?

A: Prioritize machines with strong motors, adjustable stitch length, and a walking foot for even fabric feeding. Check for wear on critical parts like the needle bar and bobbin case. Reputable brands like Juki or Singer Industrial are reliable choices for upholstery work.

Q: Are heavy duty industrial sewing machines suitable for home use?

A: While industrial machines excel in speed and durability, they require significant space and power. They’re best for high-volume projects or professional workshops. For occasional home use, a commercial-grade heavy-duty machine may be more practical.

Q: Can heavy duty sewing machines sew multiple layers of thick fabric?

A: Yes, heavy duty machines easily penetrate layers of thick materials like leather or upholstery due to their high-speed motors and specialized needles. Features like a presser foot lifter and adjustable presser foot pressure enhance precision for complex projects.

Q: How do I maintain a used industrial sewing machine?

A: Regularly clean lint and debris, oil moving parts as per the manual, and replace worn needles or belts. Inspect tension settings and test stitch quality before major projects. Proper maintenance ensures longevity and consistent performance.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025