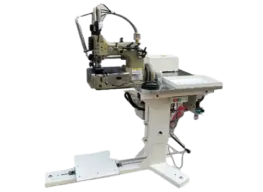

upholstery binding machine

The Importance of Upholstery Binding Machines in the Furniture Industry

Upholstery binding machines have become indispensable tools in the furniture industry, revolutionizing how fabrics are finished and secured to furniture frames. This specialized equipment not only enhances the aesthetic appeal of upholstered items but also ensures durability and function, making it a worthy investment for manufacturers and craftsmen alike.

At its core, an upholstery binding machine is designed to attach fabric edges securely to the furniture, preventing fraying and providing a clean, professional look. The process involves applying a binding material—often made from fabric, vinyl, or leather—around the edges of the upholstery to create a finished edge. This not only protects the raw edges but also adds a decorative element that can complement the overall design of the piece.

One of the main advantages of using an upholstery binding machine is the efficiency it brings to the manufacturing process. Traditional methods of binding edges often involve intricate handwork, which can be time-consuming and labor-intensive. By automating this process, upholstery binding machines significantly speed up production times, allowing manufacturers to meet demand more effectively. This efficiency is particularly vital in a fast-paced market where consumer preferences can change rapidly.

upholstery binding machine

Moreover, these machines offer a level of precision that is hard to match by hand. Upholstery binding machines can be adjusted for various fabric types and thicknesses, ensuring consistent results across different projects. This precision not only improves the quality of the finished product but also reduces material waste. By achieving a perfect fit every time, manufacturers can optimize their fabric usage, contributing to cost savings and environmental sustainability.

Additionally, the versatility of upholstery binding machines cannot be overlooked. These machines are capable of handling various binding techniques, including single-fold, double-fold, and even custom bindings. This adaptability allows artisans to experiment with different binding styles and materials, fostering creativity and innovation in upholstery design. Whether it’s for residential furniture, commercial seating, or automotive interiors, there's a binding solution available to meet diverse needs.

Maintenance and ease of use are also critical factors to consider when discussing upholstery binding machines. Most modern machines are designed with user-friendly interfaces and adjustable settings, enabling operators to quickly learn how to use them effectively. Regular maintenance is also simplified, ensuring longevity and reliability. This user-centric design minimizes downtime, keeping production lines running smoothly and efficiently.

In conclusion, upholstery binding machines play a crucial role in the contemporary furniture industry, combining efficiency, precision, and versatility. By adopting these machines, manufacturers can improve their productivity while enhancing the quality and appearance of their products. As the industry continues to evolve, incorporating advanced machinery like upholstery binding machines will be key to staying competitive and meeting the demands of an ever-changing market. Whether you are a large-scale manufacturer or a small workshop, investing in an upholstery binding machine can significantly elevate your production capabilities and craftsmanship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025