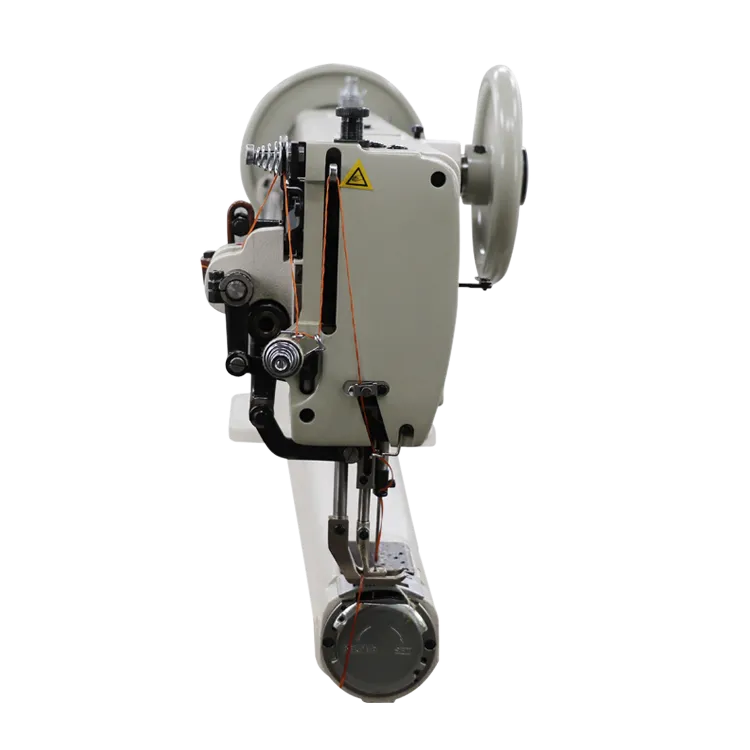

straight and zigzag industrial sewing machine

Straight and Zigzag Industrial Sewing Machines A Comprehensive Guide

In the world of garment manufacturing and crafting, industrial sewing machines have become indispensable tools that enhance productivity and precision. Among the various types of sewing machines, straight and zigzag machines are two of the most prominent. Each type serves distinct functions and offers unique benefits, making them suitable for different sewing tasks and applications.

Straight Sewing Machines Precision and Simplicity

Straight sewing machines, often referred to as lockstitch machines, are designed to create a straight stitch—a fundamental stitch used in many sewing applications. These machines are characterized by their simplicity and efficiency, making them a staple in the fashion and textile industries.

The primary advantage of a straight sewing machine is its ability to produce high-quality, durable seams quickly. This machine typically operates at high speeds, allowing for mass production of garments with a consistent stitch quality. The lockstitch produced by a straight sewing machine is formed by intertwining two threads—one from the needle and the other from a bobbin. This method not only creates a secure seam but also minimizes the likelihood of unraveling.

Moreover, straight sewing machines are versatile and can be used on various fabric types, including woven and knit fabrics. They are ideal for tasks like seaming, topstitching, and hemming. In addition, many straight sewing machines come equipped with features such as adjustable stitch lengths and automatic thread cutting, further increasing efficiency and ease of use.

Zigzag Sewing Machines Versatility and Creative Stitching

While straight sewing machines excel in creating straight stitches, zigzag machines open up a realm of creative possibilities. Zigzag sewing machines can produce not only straight stitches but also zigzag stitches of varying widths and lengths. This versatility allows them to be used for a wide range of applications, from simple sewing tasks to more complex embellishments.

straight and zigzag industrial sewing machine

The zigzag stitch is particularly useful for finishing raw edges of fabrics to prevent fraying. It is commonly employed in garment construction and quilting, where both strength and flexibility are necessary. The ability to adjust the width of the zigzag stitch means users can adapt their sewing techniques to suit different fabric types and project requirements.

In addition to edge finishing, zigzag machines also enable decorative stitching, allowing sewists to add intricate designs or features to their projects. This functionality is especially advantageous for crafters and fashion designers looking to create unique pieces.

Complementing Each Other Choosing the Right Machine

When deciding between a straight and zigzag industrial sewing machine, it is essential to consider the specific needs of a project. For most basic garment assembly tasks, a straight sewing machine may be the best choice due to its speed and efficiency. It is perfect for constructing seams and performing basic sewing operations.

Conversely, if a project requires the addition of decorative elements or finishing techniques, a zigzag machine is more suitable. The ability to perform various stitching techniques makes it a valuable asset for those who enjoy creative sewing.

In many professional settings, both types of machines are utilized—straight sewing machines for the bulk of the assembly process and zigzag machines for finishing and decorative tasks. This combination allows for a streamlined workflow and high-quality results.

Conclusion

In conclusion, straight and zigzag industrial sewing machines each have their unique strengths and applications in the sewing industry. Straight sewing machines provide the efficiency and precision needed for basic garment construction, while zigzag machines offer versatility and creativity for finishing and decorative stitching. Understanding the capabilities and suitable applications of both types of machines is crucial for anyone looking to enhance their sewing skills or improve productivity in a professional setting. With the right machine, the possibilities for creativity and craftsmanship are limitless.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025