Sewing Machines for Lifting Slings Enhance Performance and Durability

The Importance of Lifting Sling Sewing Machines in Modern Manufacturing

In the world of manufacturing and textile production, the efficiency and effectiveness of sewing machines play a crucial role in determining the quality and speed of output. Among the various types of sewing machines, the lifting sling sewing machine has carved a niche for itself, especially in industries that deal with heavy fabrics and materials. This article explores the significance of lifting sling sewing machines and their contributions to modern manufacturing techniques.

What is a Lifting Sling Sewing Machine?

A lifting sling sewing machine is specifically designed to handle heavy-duty fabrics, often used in the production of lifting slings, tarpaulins, and various industrial textiles. Unlike standard sewing machines, lifting sling sewing machines come equipped with robust features that allow them to sew thick materials with ease. They typically have powerful motors that provide the necessary torque to manage heavy threads and layers efficiently.

Key Features of Lifting Sling Sewing Machines

1. Heavy-Duty Construction These machines are built to withstand the stress of sewing tough materials. The reinforced structure ensures durability and long-lasting performance, which is essential in an industrial setting.

2. Powerful Motors The motors in lifting sling sewing machines are engineered to deliver higher torque, allowing them to sew through multiple layers of heavy fabric without compromising on speed or quality.

4. User-Friendly Controls Despite their heavy-duty capabilities, many modern lifting sling sewing machines come equipped with intuitive controls, making them easier to operate for skilled workers. Features like speed control and automatic tension adjustment further enhance user convenience.

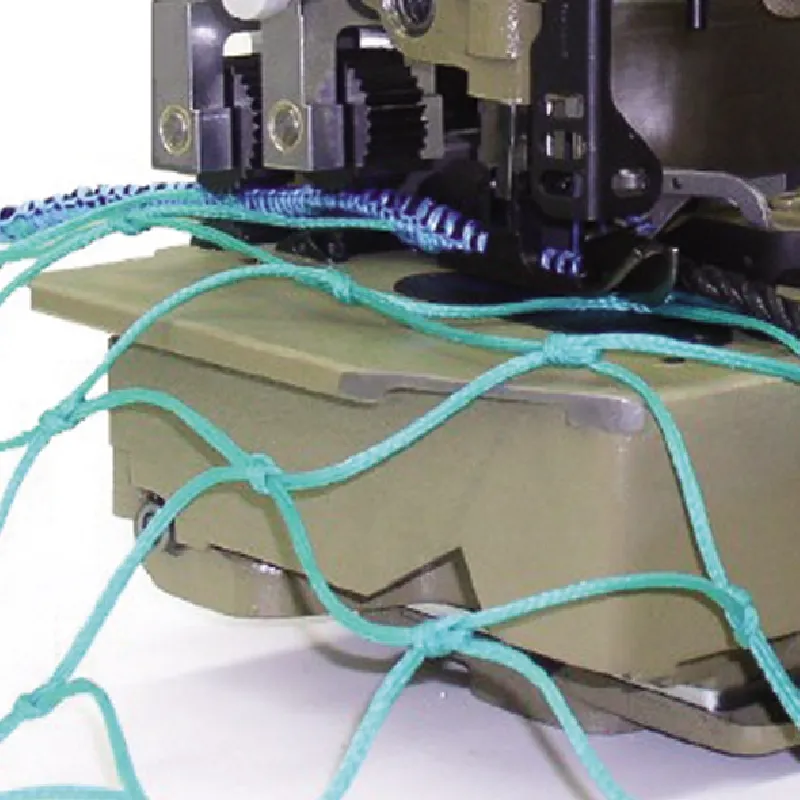

lifting sling sewing machine

Advantages in Manufacturing

1. Increased Efficiency One of the most significant advantages of using lifting sling sewing machines is the increased efficiency in production. These machines can sew faster and handle tougher materials, reducing the time it takes to complete projects.

2. Enhanced Quality The ability to sew through heavy fabrics without snags or breaks leads to a higher-quality end product, which is vital for industries where safety and durability are paramount, such as in the aerospace and construction sectors.

3. Cost-Effectiveness Though the initial investment in a lifting sling sewing machine might be higher compared to conventional machines, the long-term benefits—such as reduced labor costs and less downtime due to machine failure—make them a cost-effective option in the long run.

4. Versatility Many lifting sling sewing machines offer various stitch patterns and settings, enabling manufacturers to diversify their product offerings without needing multiple machines.

Applications

Lifting sling sewing machines are widely used in various applications, from manufacturing lifting slings for cranes and hoists to producing heavy-duty tarps and covers for industrial machinery. Their ability to handle heavy fabrics makes them indispensable in sectors such as construction, shipping, and automotive industries.

Conclusion

As industries continue to evolve and demands for high-quality, durable textiles increase, the role of lifting sling sewing machines will undoubtedly become more prominent. Their unique features and capabilities not only enhance manufacturing efficiency but also contribute to quality assurance in finished products. Investment in advanced sewing technology, such as lifting sling sewing machines, is essential for manufacturers looking to stay competitive in a fast-paced market. As the manufacturing landscape grows, so too will the importance of specialized equipment designed to tackle the challenges posed by modern production needs.

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025