Efficient Sewing Machines for Safety Harness Production and Repair Solutions

The Importance of Safety Harness Sewing Machines in Industrial Manufacturing

In the world of industrial manufacturing, safety is paramount, especially when it comes to the production of safety harnesses. These essential items are crucial for ensuring the safety of workers across various industries, including construction, mining, and electrical work. As such, the role of specialized equipment, particularly safety harness sewing machines, cannot be overstated. In this article, we will explore the significance of these machines, their features, and their impact on both the production process and overall workplace safety.

The Role of Safety Harnesses in Industry

Safety harnesses are designed to secure individuals working at heights, preventing falls and mitigating the risk of injury. Given that falls can lead to severe injuries and even fatalities, the manufacturing of robust, reliable harnesses is vital. This makes the sewing process particularly critical, as it involves stitching together strong materials—often nylon or polyester—to ensure durability and performance under stress. A safety harness sewing machine must, therefore, be equipped to handle heavy-duty fabrics and deliver consistent, high-quality stitches.

Key Features of Safety Harness Sewing Machines

Safety harness sewing machines are specialized tools tailored for the unique demands of manufacturing safety equipment. Here are some of their standout features

1. Heavy-Duty Construction These machines are built to withstand the rigors of thick webbing and heavy materials. A robust frame and reinforced parts are essential for ensuring longevity and reliability.

2. High-Speed Performance Given the high demand for safety harnesses, these machines are designed to operate at elevated speeds. This efficiency in production is critical for meeting market needs without compromising quality.

3. Precision Stitching Accuracy is vital when stitching safety gear. These machines often come equipped with advanced needle and feed mechanisms that provide precision stitching, ensuring every harness is made to stringent safety standards.

4. Variety of Stitches From straight stitches to zigzag and bar tacks, a safety harness sewing machine offers versatility in stitching options. This adaptability allows manufacturers to create different designs and styles tailored to various employment sectors.

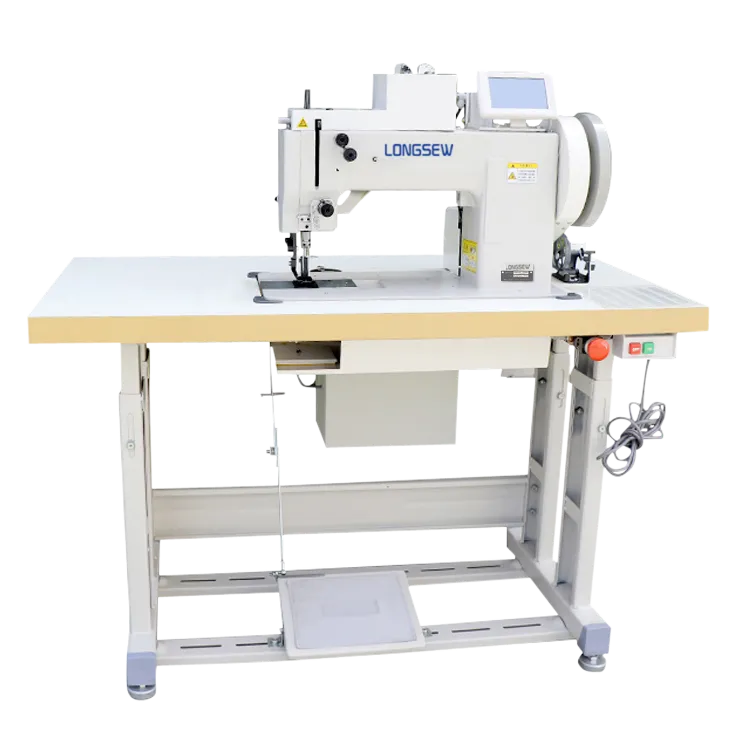

safety harness sewing machine

5. User-Friendly Controls Modern machines incorporate digital technology, making it easier for operators to set parameters, monitor performance, and adjust settings swiftly. This accessibility helps minimize human error, further increasing product safety.

Impact on Workplace Safety

The integration of safety harness sewing machines in manufacturing facilities significantly enhances workplace safety. Here are several ways this technology contributes to better outcomes

1. Reduced Risk of Product Failure With machines engineered to optimize stitch quality and durability, the risk of harnesses failing during use is dramatically decreased. This reliability is crucial in high-risk environments.

2. Increased Production Capacity By streamlining the sewing process, factories can produce a higher volume of safety harnesses in less time, ensuring that companies have enough gear for their workforce.

3. Consistent Quality Assurance Automated sewing processes help maintain uniform quality standards across batches, ensuring that each product meets the same high safety criteria.

4. Labor Efficiency With advanced machinery, skilled workers can focus on quality control and other critical tasks rather than simple sewing processes, increasing productivity and job satisfaction.

Conclusion

Safety harness sewing machines play an integral role in the industrial landscape, specifically in the manufacture of safety harnesses. By producing reliable, high-quality equipment, these machines not only protect workers but also enhance overall operational efficiency. As industries continue to evolve and prioritize safety, investing in advanced sewing technology will remain a critical step towards achieving a safer working environment. Ensuring that every harness is crafted with the utmost care and precision should be a top priority for manufacturers dedicated to protecting their workforce. In a world where safety is paramount, the significance of these specialized sewing machines cannot be ignored.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025