Feb . 15, 2025 03:19

Back to list

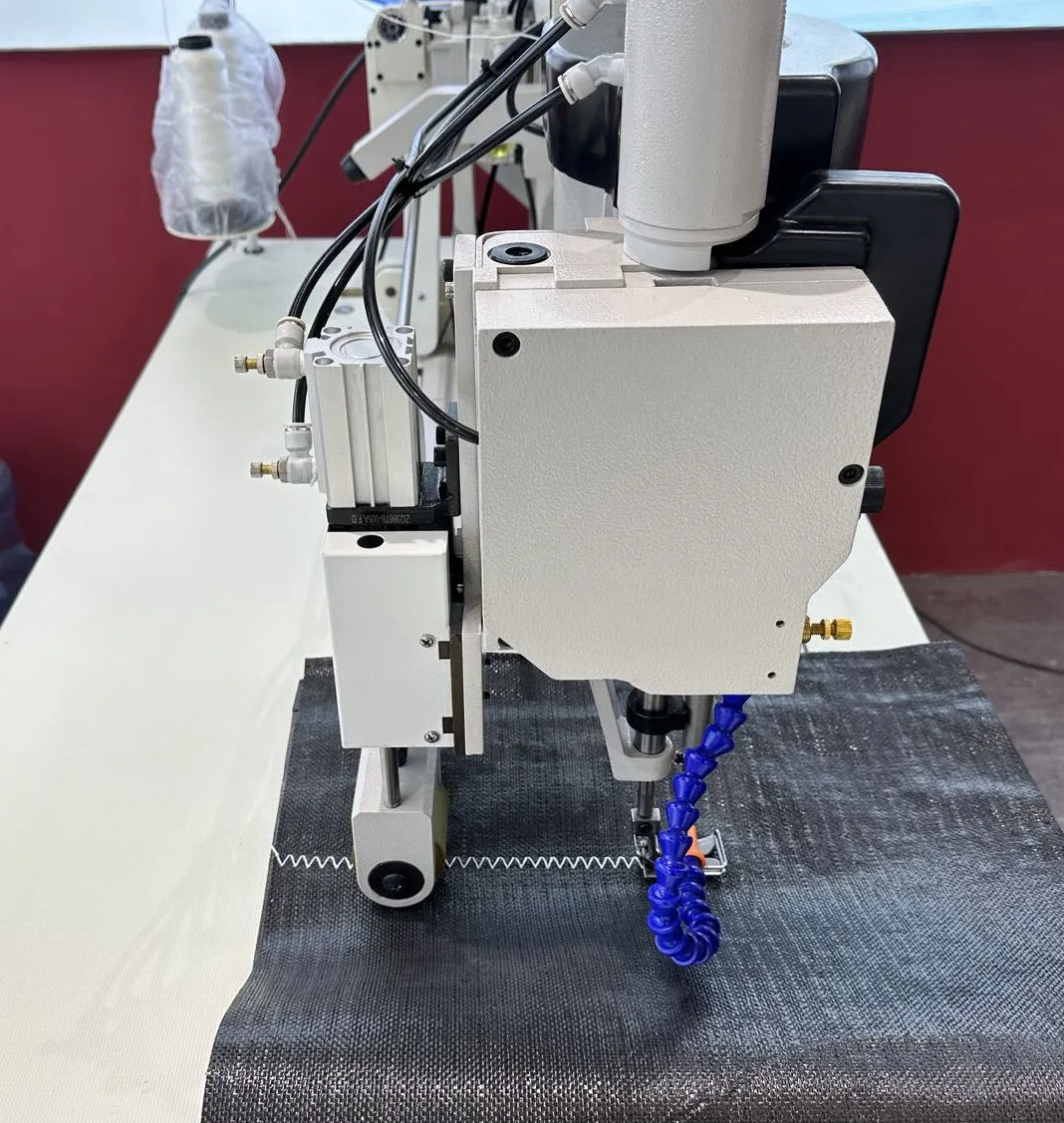

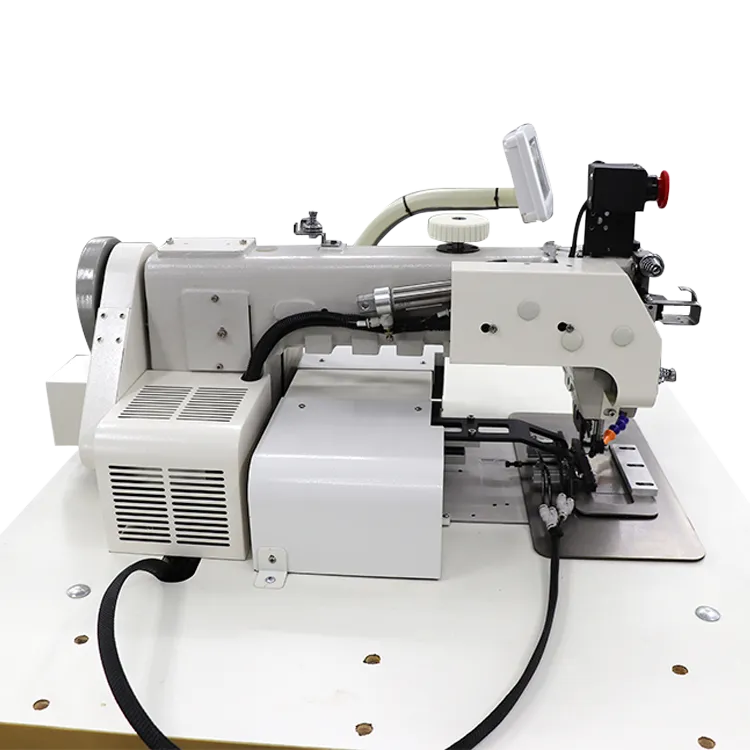

single needle bag closer sewing machine

The world of packaging solutions has witnessed a tremendous evolution over the past few decades, with the advent of advanced machinery enhancing the efficiency and accuracy of packaging tasks. One shining example in this domain is the PP bag closer machine, a sophisticated piece of equipment designed to streamline and perfect the closing of polypropylene bags. This article explores the remarkable capabilities and benefits of the PP bag closer machine, drawing from real-life experiences and expert insights.

Field experts assert that the reliability of the PP bag closer machine stands it apart as a must-have in modern packaging setups. Its capability to perform consistently over extended periods without frequent breakdowns speaks volumes of its engineering excellence. Moreover, the machine's design considerations include easy maintenance protocols. Regular upkeep involves straightforward steps that ensure longevity, thus offering an excellent return on investment — a factor that decision-makers weigh heavily when procuring industrial equipment. For firms concerned with branding and product presentation, the importance of a neat, professional finish on packaging cannot be understated. The PP bag closer machine does not merely close bags; it ensures that each seal exudes uniformity and professionalism, which can directly influence consumer perceptions. In markets where the visual appeal of a product's packaging plays a crucial role in purchase decisions, such enhancements in packaging standards can lead to increased customer satisfaction and higher sales. On the subject of sustainability — a growing concern across industries — the PP bag closer machine contributes positively. By ensuring a secure close and reducing waste due to spillage or package failures, companies can bolster their sustainability credentials. This aligns with global efforts towards more eco-friendly practices, offering companies an avenue to maintain compliance with regulations and meet customer expectations for responsible business operations. In conclusion, the PP bag closer machine epitomizes the blend of innovation, efficiency, and reliability required in modern packaging solutions. With its ability to enhance productivity, reduce operational costs, and ensure high-quality outcomes, it stands as a testament to industrial ingenuity. As businesses continue to seek competitive advantages in their operations, investing in such advanced machinery aligns with their strategic goals for growth and sustainability. For companies still relying on outdated methods, the transition to using PP bag closer machines may well be a transformational step toward achieving operational excellence and market leadership.

Field experts assert that the reliability of the PP bag closer machine stands it apart as a must-have in modern packaging setups. Its capability to perform consistently over extended periods without frequent breakdowns speaks volumes of its engineering excellence. Moreover, the machine's design considerations include easy maintenance protocols. Regular upkeep involves straightforward steps that ensure longevity, thus offering an excellent return on investment — a factor that decision-makers weigh heavily when procuring industrial equipment. For firms concerned with branding and product presentation, the importance of a neat, professional finish on packaging cannot be understated. The PP bag closer machine does not merely close bags; it ensures that each seal exudes uniformity and professionalism, which can directly influence consumer perceptions. In markets where the visual appeal of a product's packaging plays a crucial role in purchase decisions, such enhancements in packaging standards can lead to increased customer satisfaction and higher sales. On the subject of sustainability — a growing concern across industries — the PP bag closer machine contributes positively. By ensuring a secure close and reducing waste due to spillage or package failures, companies can bolster their sustainability credentials. This aligns with global efforts towards more eco-friendly practices, offering companies an avenue to maintain compliance with regulations and meet customer expectations for responsible business operations. In conclusion, the PP bag closer machine epitomizes the blend of innovation, efficiency, and reliability required in modern packaging solutions. With its ability to enhance productivity, reduce operational costs, and ensure high-quality outcomes, it stands as a testament to industrial ingenuity. As businesses continue to seek competitive advantages in their operations, investing in such advanced machinery aligns with their strategic goals for growth and sustainability. For companies still relying on outdated methods, the transition to using PP bag closer machines may well be a transformational step toward achieving operational excellence and market leadership.

Previous:

Latest news

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025