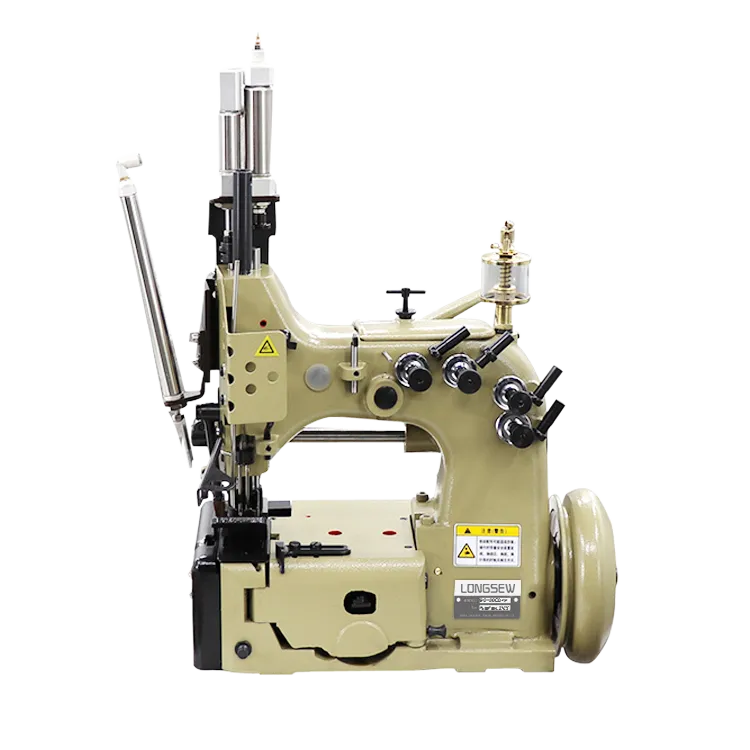

long arm sail sewing machine with puller

The Advantages of Long Arm Sail Sewing Machines with Pullers

In the world of textile and sail manufacturing, efficiency and precision are paramount. One of the most significant advancements in this field is the long arm sail sewing machine with a puller. This innovative machinery has transformed the process of sewing heavy materials used in sails and other large fabric applications.

A long arm sail sewing machine is designed with an extended arm capable of accommodating larger fabric pieces. This feature is essential for working with sails, which can be quite extensive due to their size and dimensional requirements. Traditional sewing machines often struggle with larger projects, leading to frustration and inefficiencies. The long arm design provides a more significant workspace, allowing operators to maneuver bulky materials without compromising the stitching quality.

An integral feature of these machines is the puller attachment. This mechanism assists in feeding the fabric through the sewing machine, ensuring a smooth and consistent flow. When working with heavy materials like those used in sail production, maintaining tension and alignment is crucial. The puller helps manage the fabric’s movement, preventing bunching or shifting, which can lead to uneven seams or, worse, damage to the material.

The combination of a long arm and puller offers several advantages. First, it greatly increases productivity. Operators can complete projects faster and with less physical strain, as the puller takes on much of the workload associated with moving heavy materials. This efficiency translates to higher output for businesses, allowing them to meet the demands of their customers more effectively.

long arm sail sewing machine with puller

Moreover, the precision gained through this technology enhances seam quality. In sail making, the integrity of the seams is critical; any imperfections can lead to failure under stress. The consistent tension maintained by the puller minimizes the risk of puckering or uneven stitching. As a result, the final product not only looks professional but also performs reliably on the water.

In addition, long arm sail sewing machines with pullers can accommodate various stitching styles and techniques, enhancing versatility. Sail manufacturers often need to execute different seam types, such as flat felled or zig-zag stitches, depending on the application. These machines can seamlessly transition between styles, ensuring that every seam is executed with precision and care.

Finally, investing in a long arm sail sewing machine with a puller can yield long-term savings. While the initial cost may be higher than traditional machines, the increased efficiency, reduced waste, and enhanced product quality can lead to greater profitability over time.

In summary, long arm sail sewing machines with pullers are essential tools for anyone in the sail manufacturing industry. They offer enhanced productivity, precision, and versatility, making them invaluable in producing high-quality sails that can withstand the elements. With these advanced machines, manufacturers can meet the growing demands of the market while ensuring top-notch craftsmanship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025