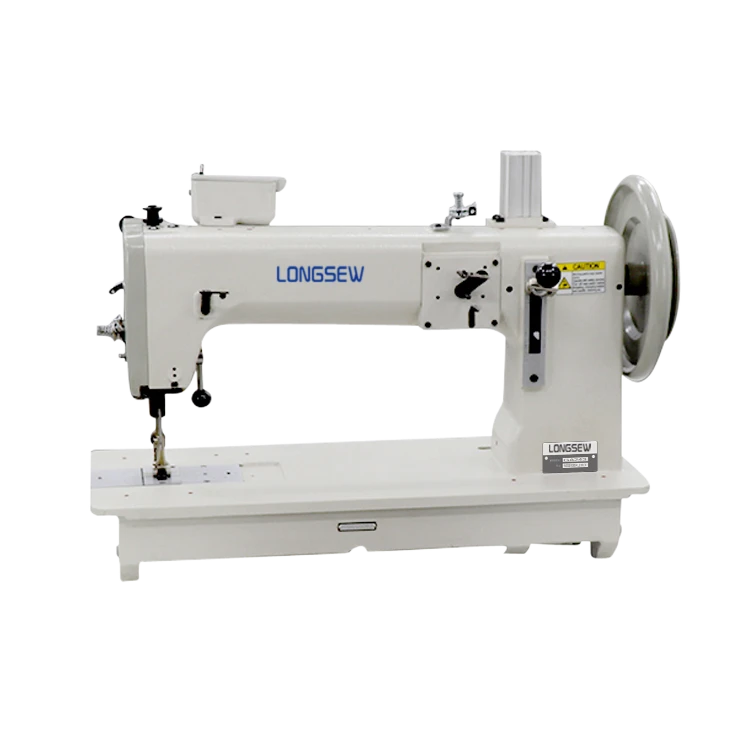

lock stitch sewing machine

Lock Stitch Sewing Machines An Overview

Lock stitch sewing machines are a cornerstone of the textile and garment manufacturing industry. These machines utilize a unique mechanism to create a secure and durable stitch, making them essential for both industrial applications and home sewing. Understanding the operation, benefits, and types of lock stitch sewing machines can enhance one’s sewing experience and improve the quality of finished products.

A lock stitch sewing machine works by using two threads the upper thread and the lower thread. The upper thread passes through a needle, while the lower thread is fed from a bobbin located beneath the sewing surface. The machine’s mechanism interlocks these two threads at the fabric layers, forming a strong stitch that is resistant to unraveling. This mechanism not only provides durability but also creates a beautiful finish, making it suitable for a variety of fabrics and sewing projects.

One of the primary advantages of lock stitch machines is their versatility. They can sew through multiple layers of fabric, making them ideal for constructing items such as clothing, upholstery, and bags. Additionally, they produce a flat and neat seam, which is particularly desirable in garments where appearance matters. The lock stitch's capability to handle different weights of fabric—ranging from delicate silks to heavy denim—also sets it apart from other types of sewing machines.

lock stitch sewing machine

Lock stitch sewing machines come in various models suited for different sewing needs. The most common type is the domestic sewing machine, which is designed for home use. These machines typically feature a variety of stitch options, allowing users to create decorative and functional stitches as needed. They are user-friendly, often equipped with automatic needle threading, adjustable stitch length, and speed settings, making them accessible for beginners and experienced sewers alike.

On the industrial side, lock stitch sewing machines are available in heavy-duty configurations designed for high production environments. These machines are built to withstand constant use and can sew at much faster speeds compared to domestic models. Features may include larger bobbins, automatic threading systems, and enhanced sewing technologies that ensure precision and reliability in mass production settings. Industries ranging from fashion to automotive rely on these powerful machines to meet their production demands.

Maintenance is crucial for the longevity and performance of lock stitch sewing machines. Regular cleaning to prevent dust and lint buildup, along with timely oiling of moving parts, helps maintain smooth operation. Additionally, users should regularly check and replace needles and thread as necessary to ensure the best sewing quality.

In conclusion, lock stitch sewing machines play a vital role in the sewing world, providing strength, versatility, and excellent seam quality. Whether for personal projects or industrial applications, understanding how to utilize and maintain these machines can significantly impact the outcome of sewing endeavors. As technology continues to evolve, the features and capabilities of lock stitch machines will likely expand, enabling even more creative possibilities for sewers worldwide.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025