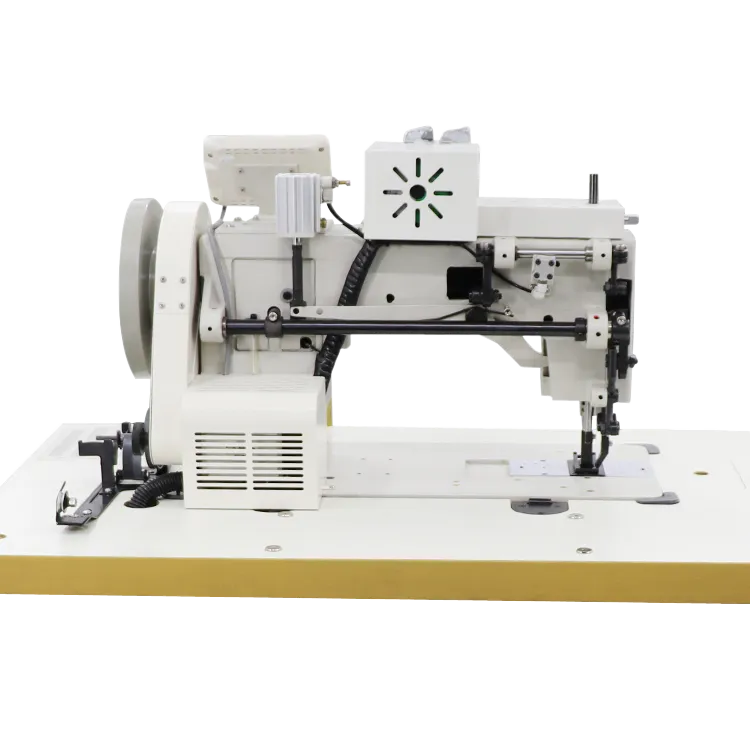

industrial leather sewing machine

The Importance of Industrial Leather Sewing Machines in Modern Manufacturing

In the world of textile production, leather holds an esteemed position due to its durability, aesthetic appeal, and versatility. As the demand for leather products continues to rise, the need for efficient and robust sewing solutions becomes increasingly critical. This is where industrial leather sewing machines play a pivotal role. Designed specifically for heavy-duty applications, these machines provide manufacturers with the tools necessary to create high-quality leather goods efficiently and effectively.

Industrial leather sewing machines are built to withstand the rigors of continuous use. Unlike regular sewing machines, which are often suited for lighter fabrics, these specialized machines are equipped with powerful motors and reinforced construction to handle the thickness and toughness of leather. This capability not only increases productivity but also reduces wear and tear on the machinery, ensuring longevity and reliability.

One of the standout features of industrial leather sewing machines is their ability to perform various stitching techniques. From straight stitching to decorative patterns, these machines can adapt to different manufacturing needs and styles. This versatility is invaluable in the leather goods industry, where the quality of stitching can significantly impact the final product's appearance and durability. Manufacturers benefit from the precision and consistency these machines offer, leading to higher quality standards and customer satisfaction.

industrial leather sewing machine

Moreover, advancements in technology have led to the development of computerized industrial leather sewing machines. These modern machines come equipped with programmable features, allowing manufacturers to save specific stitch patterns and replicate them effortlessly. This technology not only streamlines production but also opens the door to intricate designs and customizations that would be challenging to achieve manually. As consumer preferences shift towards personalized and unique products, the ability to easily implement such features can provide companies with a competitive edge.

In addition to efficiency and versatility, industrial leather sewing machines are designed with safety in mind. Leather sewing processes often involve sharp needles and significant tangential forces. Therefore, modern machines incorporate safety features such as automatic needle positioning and protective shields to prevent accidents and injuries in the workplace. This commitment to safety ensures that manufacturers can operate their facilities with peace of mind, fostering a productive work environment.

Lastly, the investment in industrial leather sewing machines can lead to significant cost savings in the long run. While the initial purchase may be higher than that of standard sewing machines, the durability, lower maintenance costs, and increased production output can ultimately result in a favorable return on investment. As companies strive to optimize their operations and boost profitability, these machines can serve as indispensable assets.

In conclusion, industrial leather sewing machines are crucial components in the modern manufacturing landscape. Their robust construction, versatility in stitching options, technological advancements, safety features, and potential for cost savings position them as essential tools for any enterprise involved in leather production. As the industry evolves, these machines will undoubtedly continue to play a vital role in meeting the demands of an increasingly discerning market for high-quality leather goods.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025