High-Quality Spout Sewing Machines for FIBC Bag Production and Efficiency

Understanding FIBC Spout Sewing Machines Enhancing Efficiency in Bulk Packaging

In the modern industrial landscape, the efficient packaging of bulk materials has become a crucial aspect of many manufacturing processes. Among the various tools that facilitate this, FIBC (Flexible Intermediate Bulk Container) spout sewing machines have gained prominence. These specialized machines are designed to optimize the sewing of spouts on FIBCs, which are widely used for transporting granular products like chemicals, food, and agricultural materials. This article explores the significance, functioning, and benefits of FIBC spout sewing machines.

What is an FIBC Spout?

FIBCs are large flexible bags capable of holding substantial volumes of powdered or granular materials. The spout refers to the opening at the bag's top or bottom that allows for easy filling or discharging of contents. A well-constructed spout is vital in ensuring that the bag can be filled and emptied efficiently while minimizing spillage and contamination.

Why Use an FIBC Spout Sewing Machine?

Sewing spouts onto FIBCs requires precision and durability. Traditional sewing methods may not provide the necessary strength and consistency, leading to potential failures during transportation or storage. FIBC spout sewing machines address these issues by offering

1. Speed and Efficiency Automated sewing machines are significantly faster than manual sewing. They can produce several bags per hour, which enhances production efficiency and reduces labor costs.

2. Consistent Quality These machines are designed to provide uniform stitching quality, ensuring that each spout is securely attached and meets industry standards. This consistency minimizes the risk of defects that can occur with manual sewing.

3. Strength and Durability FIBC spout sewing machines use robust materials and advanced stitching techniques, resulting in spouts that can withstand the rigors of transportation. This contributes to the overall safety and reliability of the packaged goods.

4. Customization Options Many modern FIBC sewing machines can be adjusted to cater to different bag sizes and spout designs, allowing manufacturers to meet specific customer requirements.

How Does an FIBC Spout Sewing Machine Work?

The operation of an FIBC spout sewing machine typically involves several key steps

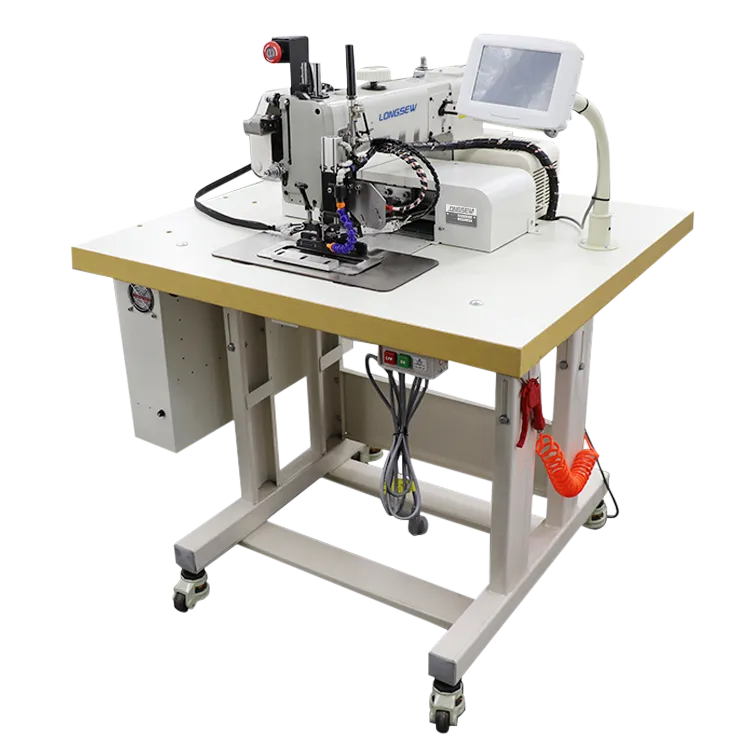

fibc spout sewing machine

1. Material Feeding The operator loads fabric rolls onto the machine, which automatically feeds the material into the sewing area.

2. Pattern Setup Depending on the design of the FIBC and the spout, the machine can be programmed with various stitching patterns that best suit the project requirements.

3. Sewing Process The machine uses specialized sewing techniques to attach the spout to the body of the FIBC securely. This process may involve multiple passes to ensure strength.

4. Quality Control Many machines come equipped with sensors and monitoring systems that ensure each stitch is executed correctly, alerting operators to any discrepancies.

5. Output Handling Once the spout has been successfully sewn, the finished FIBC can be automatically cut and ejected for further use.

The Advantages of Investing in FIBC Spout Sewing Machines

For businesses involved in bulk packaging, investing in an FIBC spout sewing machine can yield significant returns. Here are some of the advantages

- Cost Savings Reduced labor costs and increased production speed contribute to improved profit margins. The durability of sewn spouts also means fewer complaints and replacements, saving money in the long run.

- Improved Safety A well-sewn spout reduces the risk of spillage, protecting both the product and the personnel involved in handling the FIBC.

- Enhanced Productivity With faster turnaround times and less need for manual intervention, companies can increase their overall productivity, allowing them to meet rising market demands.

Conclusion

FIBC spout sewing machines represent a vital technological advancement in the bulk packaging sector. By automating the sewing process, manufacturers can achieve greater efficiency, consistency, and safety in their operations. As industries continue to evolve, the adoption of such specialized machinery will undoubtedly play a significant role in driving productivity and ensuring the high standards expected in the global marketplace. With the growing demand for FIBCs across various sectors, investing in advanced sewing technology is more critical than ever for staying competitive and responsive to market needs.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025