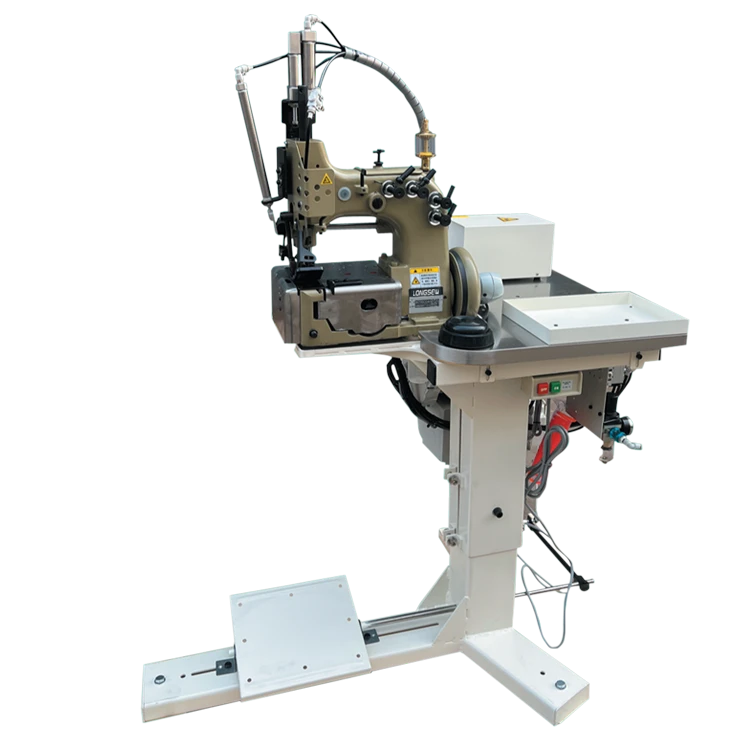

fibc sewing machine

The Essential Role of FIBC Sewing Machines in Modern Industry

In the modern manufacturing landscape, the production of Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, has gained significant importance. These versatile containers are widely used for transporting bulk materials across various industries, including agriculture, construction, chemicals, and food processing. To meet the growing demand for FIBCs, specialized machinery, such as FIBC sewing machines, plays a crucial role in their production.

FIBC sewing machines are specifically designed to handle the unique requirements of sewing bulk bags, which are typically made from woven polypropylene fabric. This fabric is not only strong and durable but also lightweight, making it ideal for storing and transporting bulk goods. The sewing machines used for FIBCs must accommodate heavy-duty sewing applications, as these bags often need to withstand considerable weight and handling during transportation.

The Essential Role of FIBC Sewing Machines in Modern Industry

The design and functionality of these machines also emphasize versatility. Manufacturers can adjust the settings to produce various bag styles, such as open-top, closed, or with spouts for easy filling and discharge. Furthermore, FIBC sewing machines can accommodate various thread types to ensure that the seams remain intact under stress and during handling, providing safety and security for the contents inside.

fibc sewing machine

Another vital aspect of FIBC sewing machines is their role in enhancing the durability and hygiene of the bags produced. Many industries, especially those dealing with food products, require high hygiene standards. FIBC sewing machines often incorporate features that minimize contamination risks, such as easy-to-clean surfaces and components. Additionally, manufacturers can utilize virgin polypropylene material for the bags, ensuring the safe transport of sensitive products.

Sustainability is also becoming an increasingly important consideration in manufacturing. FIBC sewing machines can contribute to environmentally friendly practices by enabling the production of reusable and recyclable bulk bags. The durability and robustness of FIBCs reduce the need for single-use packaging, helping industries move towards more sustainable practices.

Moreover, the technological advancements in sewing machine design, such as computerized controls and automation capabilities, have revolutionized FIBC production. These features allow for precise stitching and monitoring, drastically reducing human error and enhancing overall efficiency. With the ability to integrate with other automated processes, manufacturers can optimize their production lines, resulting in reduced labor costs and improved output.

In conclusion, FIBC sewing machines are indispensable in the production of flexible intermediate bulk containers. Their specialized design, durability, and adaptability to various manufacturing needs make them a vital component for businesses aiming to meet the demands of diverse industries. As the need for efficient, sustainable, and high-quality packaging solutions continues to grow, the role of FIBC sewing machines will remain pivotal in shaping the future of bulk bag production. By investing in this essential machinery, manufacturers can ensure they remain competitive and responsive to market changes while maintaining the highest standards of quality and safety.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025