Ene . 09, 2025 12:34

Back to list

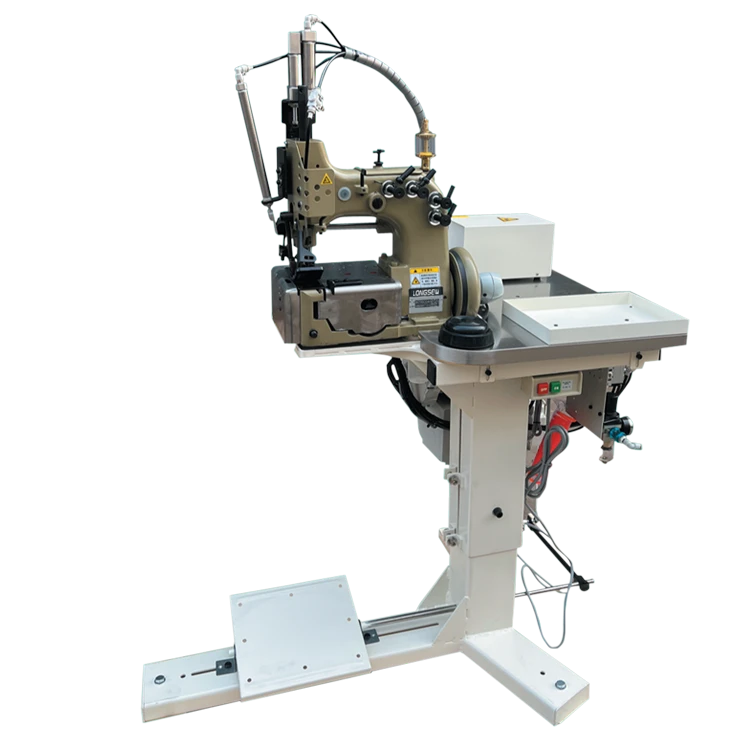

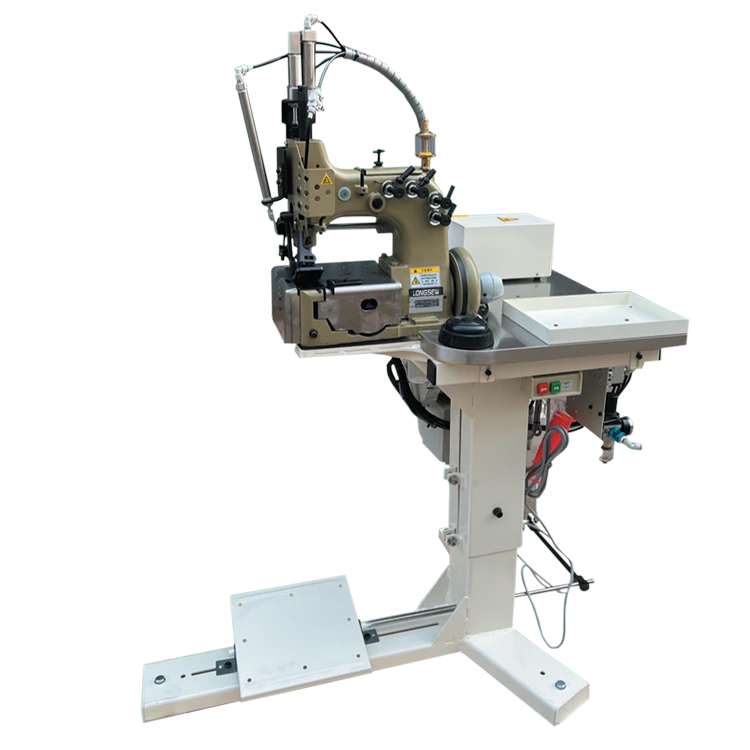

fibc sewing machine

In the ever-evolving landscape of industrial packaging, the significance of FIBC (Flexible Intermediate Bulk Containers) sewing machines cannot be overstated. Having spent over two decades entrenched in the intricacies of this field, my experience attests to the transformative impact these machines have on the packaging industry.

Authoritativeness in the realm of FIBC sewing machines is supported by industry standards and certifications. Machines that comply with international quality certifications such as ISO 9001 and CE marking give businesses the confidence that they are using equipment that meets rigorous standards for safety and performance. Furthermore, comprehensive training programs provided by manufacturers ensure that operators are knowledgeable about machine maintenance and optimization, further enhancing the authoritative value of these machines within the industry. Trustworthiness is paramount, particularly in a sector where the safety and quality of the end product are directly tied to the production process. Manufacturers of FIBC sewing machines often have a long-standing reputation for reliability, which is maintained through regular technological advancements and customer support initiatives. The feedback loop from end-users back to manufacturers plays a critical role in the ongoing enhancement of these machines, ensuring they remain at the forefront of innovation and meets the evolving needs of the packaging industry. In conclusion, the integration of FIBC sewing machines into production lines is not just a matter of operational necessity; it is a strategic decision that can significantly impact a company's competitive edge. The investment in quality machines, backed by extensive experience, technical expertise, adherence to authoritative standards, and a reputation for trustworthiness, marks a commitment to excellence and reliability in industrial packaging. As we navigate the future, these machines will undoubtedly continue to shape the efficiency and efficacy of bulk packaging solutions worldwide, underscoring their indispensable role in industrial operations.

Authoritativeness in the realm of FIBC sewing machines is supported by industry standards and certifications. Machines that comply with international quality certifications such as ISO 9001 and CE marking give businesses the confidence that they are using equipment that meets rigorous standards for safety and performance. Furthermore, comprehensive training programs provided by manufacturers ensure that operators are knowledgeable about machine maintenance and optimization, further enhancing the authoritative value of these machines within the industry. Trustworthiness is paramount, particularly in a sector where the safety and quality of the end product are directly tied to the production process. Manufacturers of FIBC sewing machines often have a long-standing reputation for reliability, which is maintained through regular technological advancements and customer support initiatives. The feedback loop from end-users back to manufacturers plays a critical role in the ongoing enhancement of these machines, ensuring they remain at the forefront of innovation and meets the evolving needs of the packaging industry. In conclusion, the integration of FIBC sewing machines into production lines is not just a matter of operational necessity; it is a strategic decision that can significantly impact a company's competitive edge. The investment in quality machines, backed by extensive experience, technical expertise, adherence to authoritative standards, and a reputation for trustworthiness, marks a commitment to excellence and reliability in industrial packaging. As we navigate the future, these machines will undoubtedly continue to shape the efficiency and efficacy of bulk packaging solutions worldwide, underscoring their indispensable role in industrial operations.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025