fibc safety sewing

The Importance of Safety in FIBC Sewing

When it comes to bulk material handling, Flexible Intermediate Bulk Containers (FIBCs) are a popular choice due to their efficiency and versatility. However, the safety of these containers heavily relies on the quality of their manufacturing, particularly in the sewing process. Understanding the significance of safety in FIBC sewing is crucial for manufacturers, users, and regulators alike.

FIBC sewing involves stitching together fabric components that form the body of the container. The safety of these seams is paramount, as they bear the weight of the contents and should withstand various environmental factors such as moisture, temperature changes, and mechanical stress. Poor sewing practices can lead to seam failures, which may result in product loss and hazardous spills.

The Importance of Safety in FIBC Sewing

The sewing technique employed is equally important. Double-stitched seams are often recommended as they provide additional strength. Moreover, the use of reinforced corners and loops can enhance load distribution and reduce stress on the seams. Regular training for the sewing operators is essential to maintain high standards, ensuring they are skilled in proper sewing techniques and understand the importance of adhering to safety protocols.

fibc safety sewing

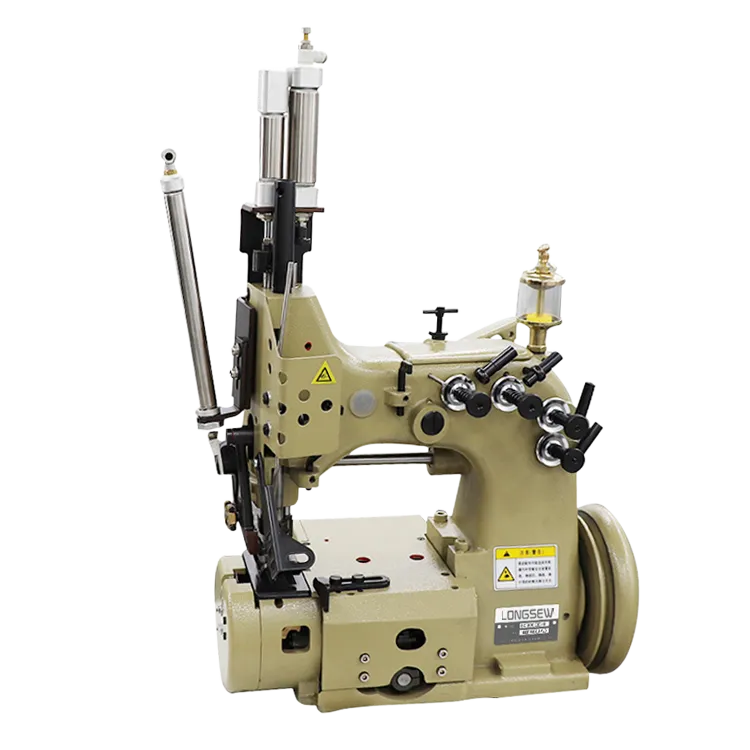

Quality control processes must be implemented throughout the sewing phase. This includes inspecting seams for consistency, strength, and overall integrity. Utilizing automated sewing machines equipped with quality monitoring systems can significantly reduce the risk of human error, resulting in a more reliable final product.

Furthermore, regular testing of finished FIBCs should be conducted to ensure they meet safety regulations and industry standards. This includes load testing to evaluate the performance of seams under various conditions. Compliance with international standards, such as those set by the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), is critical for ensuring that the FIBCs are safe for use in diverse applications.

In addition to manufacturing practices, the end-users of FIBCs must also be educated about their safe handling and storage. Understanding the weight limits, proper loading techniques, and environmental considerations can significantly mitigate the risk of incidents related to FIBC failures.

In summary, safety in FIBC sewing is a multi-faceted issue that encompasses material selection, sewing techniques, quality control, and user education. By prioritizing these aspects, manufacturers can produce reliable FIBCs that meet safety standards, thereby protecting both users and the environment. Continuous improvement in sewing practices and adherence to safety protocols will lead to enhanced quality and safety in the handling of bulk materials, making FIBCs an even more trusted solution in various industries.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025