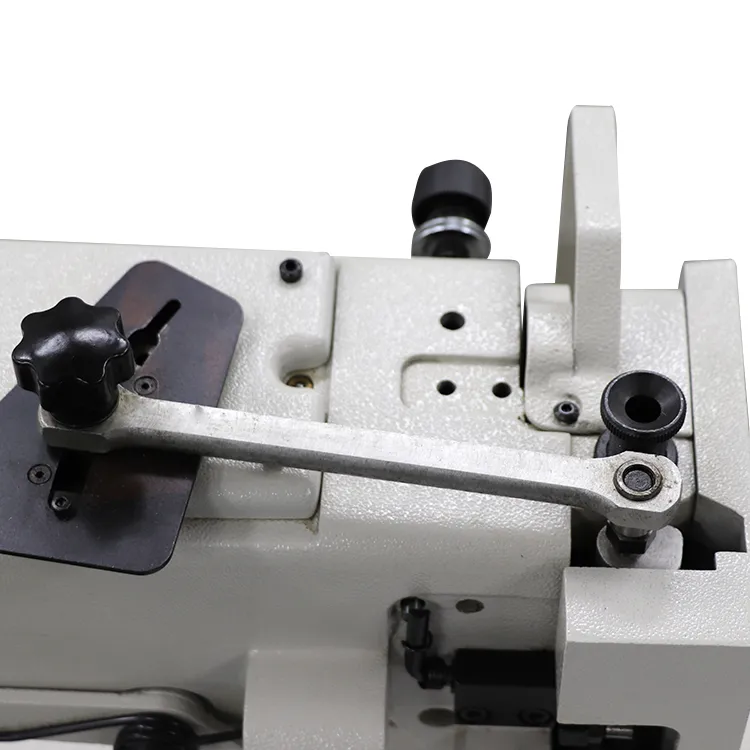

fibc overlock sewing machine

The FIBC Overlock Sewing Machine Revolutionizing Bulk Bag Production

In the rapidly evolving world of textile manufacturing, efficiency and precision are paramount, especially in the production of Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags. Among the key players in this industry is the FIBC overlock sewing machine, a specialized piece of equipment designed to enhance the quality and productivity of bulk bag production.

Understanding FIBC

Flexible Intermediate Bulk Containers are large bags used for storing and transporting various materials, including grains, chemicals, and construction materials. They are favored for their durability, lightweight design, and ability to hold large quantities, making them a staple in numerous industries. However, the production of these bags requires highly specialized sewing techniques to ensure they can withstand the demands of transportation and storage.

The Role of Overlock Sewing Machines

Overlock sewing machines, also known as sergers, are essential tools in the textile industry. They create a clean, professional finish by trimming the fabric edge and preventing fraying, which is particularly important for the longevity and strength of FIBCs. These machines operate by using multiple threads and needles to sew, cut, and finish the edges of fabric simultaneously, significantly increasing efficiency in the sewing process.

Features of FIBC Overlock Sewing Machines

FIBC overlock sewing machines come equipped with various features tailored for the production of bulk bags. Their high-speed operation allows manufacturers to produce large quantities quickly, while specialized presser feet enable smooth handling of thick, multi-layered fabrics typically used in bulk bags. Additionally, innovative tension control systems ensure that the stitches remain consistent, contributing to the overall strength and durability of the final product.

fibc overlock sewing machine

Moreover, many modern overlock machines incorporate digital technology, allowing for programmable settings that facilitate precision sewing. This is particularly beneficial in industries where consistency and quality control are crucial, as it reduces human error and enhances product uniformity.

Benefits of Using Overlock Sewing Machines in FIBC Production

The use of overlock sewing machines in the production of FIBCs offers numerous advantages. First and foremost, they significantly reduce production time, enabling manufacturers to meet the growing demand for bulk bags more effectively. This efficiency translates into cost savings, making it an attractive proposition for businesses looking to boost their bottom line.

Additionally, the superior stitching quality provided by overlock machines ensures that FIBCs can withstand the rigors of handling and transportation. This durability not only protects the contents of the bags but also enhances customer satisfaction, leading to repeat business and positive referrals.

Furthermore, the versatility of overlock machines allows manufacturers to produce a wide range of bag styles and sizes, catering to various customer needs. This adaptability is crucial in today’s competitive market, where customization and flexibility are highly valued.

Conclusion

As the demand for FIBCs continues to expand across various industries, the role of specialized equipment like the overlock sewing machine becomes increasingly significant. By investing in these advanced machines, manufacturers can enhance their production capabilities, ensure high-quality finished products, and ultimately drive their business success. The FIBC overlock sewing machine is not just a tool; it is a revolutionary asset that shapes the future of bulk bag production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025