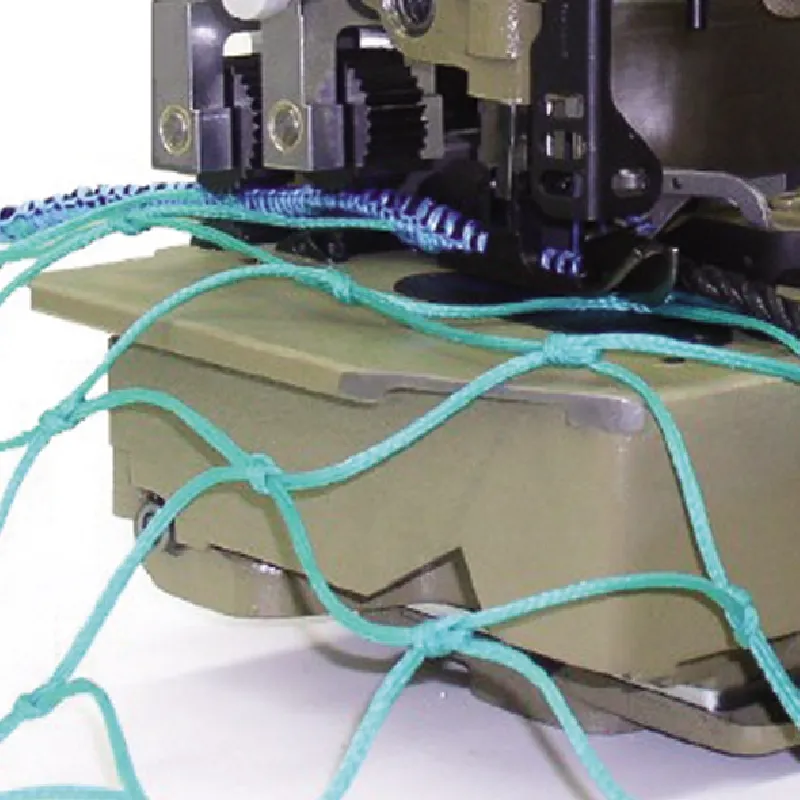

fibc bag lockstitch

Understanding FIBC Bag Lockstitch A Comprehensive Overview

The Flexible Intermediate Bulk Container (FIBC), often referred to as big bags or bulk bags, has become an indispensable part of various industries, notably in construction, agriculture, and food processing. These versatile bags are designed for the bulk handling of dry, flowable products such as grains, powders, and granules. Among the many aspects that define the quality and functionality of FIBC bags, the type of stitch used in their construction is paramount. In this context, the lockstitch method has gained significant attention.

What is Lockstitch?

Lockstitch is a common stitching technique where a needle and a bobbin thread intertwine to create a strong, secure seam. This method produces a stitch that is durable and resistant to unraveling, making it ideal for applications that require high tensile strength. In the production of FIBC bags, lockstitching is preferred for various reasons, including its ability to hold weight effectively, resistance to stress, and overall longevity.

Importance of Lockstitch in FIBC Bags

1. Strength and Durability The lockstitch method offers enhanced strength compared to other stitching techniques. Given that FIBC bags are often filled with heavy materials, it is crucial that the stitching can withstand significant loads without breaking. The intertwined threads of the lockstitch provide a robust seam that minimizes the risk of tearing, even under heavy use.

2. Resistance to Unraveling One of the key advantages of lockstitch is its ability to remain intact under duress. In scenarios where bags are dropped, pulled, or subjected to rough handling, the lockstitch ensures that the seam will not easily come undone. This reliability is especially important in industries where the safe transport of materials is critical.

3. Weight Distribution Proper stitching is vital for even weight distribution of the contents within the bag. Lockstitching enables a consistent seam that helps maintain the shape of the bag, preventing localized stress points that could lead to failure. This characteristic ensures that FIBC bags can be handled and transported efficiently.

fibc bag lockstitch

4. Versatility The lockstitch technique is versatile and can be applied to various fabrics and designs of FIBC bags. Whether the bag is made from woven polypropylene, polyethylene, or other materials, lockstitch is adaptable and remains effective across different applications.

5. Cost-Effectiveness While there are various stitching methods available, lockstitch tends to be more cost-effective in the long run. Due to its durability, bags stitched with this method require fewer repairs or replacements, translating to lower overall costs for manufacturers and users alike.

Applications of Lockstitch FIBC Bags

Lockstitch FIBC bags are widely utilized in many sectors. In the agricultural industry, these bags are commonly used for storing grains, seeds, and fertilizers. Their ability to protect contents from moisture and contaminants is essential in preserving product quality.

In construction, lockstitch bags are frequently employed to hold and transport sand, gravel, and other building materials. The strength of the stitching allows these bags to be safely lifted by cranes or other heavy machinery without fear of ripping or tearing.

Additionally, the food industry benefits from the use of lockstitch FIBC bags, especially for products like flour, sugar, and other powdered substances. The secure stitching ensures that the contents remain safe and uncontaminated during storage and transportation.

Conclusion

In summary, the lockstitch method is a critical element in the manufacturing of FIBC bags, offering superior strength, durability, and reliability. As industries continue to rely on bulk bags for efficient handling and transportation of materials, the importance of quality stitching cannot be overstated. Understanding the features and benefits of lockstitching not only aids manufacturers in choosing the right methods for their products but also informs end-users about the quality and reliability they can expect from their FIBC bags. Whether for agriculture, construction, or food processing, lockstitch FIBC bags embody a blend of functionality and robustness essential for modern industrial applications.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025