FIBC Bag Sewing Machines-Long Sewing Machinery|Double-Needle Overlocking&Chain-Stitch Technology

High-Efficiency FIBC Bag Sewing Machines: Enhancing Production for Industrial Packaging

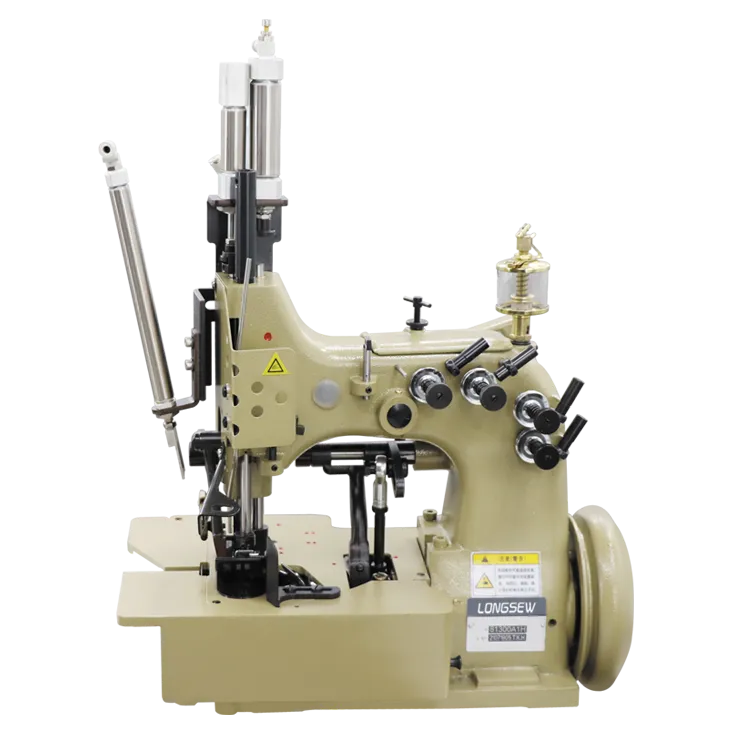

Long Sewing Machinery Co., Ltd. is a leading manufacturer of industrial sewing solutions, specializing in advanced machinery for FIBC Bag (Flexible Intermediate Bulk Container) production. Our 81300A, 81300A1, and 81300A1H models are engineered to deliver precision, durability, and efficiency in big bag manufacturing. These machines combine double-needle overlocking and chain-stitch technologies to meet the demanding requirements of modern industrial packaging.

Understanding FIBC Bag Sewing Machines

FIBC bags are essential for bulk material handling in industries such as agriculture, chemicals, and construction. These large containers require robust stitching to ensure structural integrity during transportation and storage. Our 81300A series machines address this need with advanced sewing technologies:

- Double-Needle Overlocking: Creates a reinforced edge finish, preventing fraying and enhancing durability.

- Chain-Stitch Sewing: Provides strong, flexible seams that withstand heavy loads and dynamic stress.

Market Demand and Industry Challenges

The global demand for FIBC bags is rising due to their cost-effectiveness and versatility. However, traditional sewing methods often face challenges such as:

- Inconsistent seam quality leading to product failures.

- High labor costs and slow production cycles.

- Environmental concerns from material waste.

Our 81300A series directly addresses these issues. By integrating automated double-needle and chain-stitch systems, the machines reduce manual intervention, improve seam consistency, and minimize fabric waste. This aligns with industry trends toward sustainable and efficient manufacturing.

Company Expertise and Technological Innovation

With over two decades of experience in industrial sewing machinery, Long Sewing Machinery has established itself as a trusted partner for manufacturers worldwide. Our R&D team continuously innovates to meet evolving industry standards, ensuring our machines remain at the forefront of technology. Key advantages include:

- Patented double-needle overlocking mechanisms for superior edge finishing.

- Customizable chain-stitch configurations to accommodate various fabric types.

- Compliance with international safety and quality certifications (ISO 9001, CE).

Proven Performance and Customer Testimonials

Customers report significant improvements in production efficiency after adopting our 81300A series. For example:

"Since implementing the 81300A1 model, our output has increased by 40% while reducing material waste by 25%." - Asia-Pacific Agri-Pack Ltd.

Another user noted: "The machine's precision stitching has eliminated seam failures, boosting our customer satisfaction rates." - EuroChem Solutions

Implementation and Customization

Our machines are designed for seamless integration into existing production lines. We offer:

- Technical Support: On-site installation and operator training.

- Custom Configurations: Tailored settings for specific fabric thicknesses and bag sizes.

- Warranty: 12-month coverage for key components.

Safety and Environmental Compliance

All 81300A series machines meet stringent safety standards, featuring:

- Emergency stop systems and protective guards.

- Low-energy consumption designs to reduce carbon footprint.

- Non-toxic materials for worker safety.

Logistics and Packaging

We provide secure packaging solutions for bulk orders, including:

- Wooden crates for international shipments.

- Customized labeling for easy identification.

- Experienced logistics partners for timely delivery.

Comprehensive After-Sales Support

Our commitment to clients includes:

- 24/7 technical hotline for urgent assistance.

- Regular maintenance schedules to optimize machine lifespan.

- Online resource center with manuals and troubleshooting guides.

Contact Us for Industrial Packaging Solutions

Ready to elevate your FIBC bag production? Explore our product range or contact us directly:

- Phone: +86-21-5588-XXXX

- Email: sales@longsew.com

- Website: www.longsew.com

FAQ

Q: What materials can the 81300A series handle?

A: The machines are compatible with woven polypropylene, polyester, and other industrial fabrics commonly used in FIBC bag production.

Q: How long does installation take?

A: Standard installation requires 2-3 days, depending on factory layout and customization needs.

Q: Can the machine be upgraded with new features?

A: Yes, our modular design allows for hardware and software upgrades to adapt to future production requirements.

Conclusion

Long Sewing Machinery's 81300A series FIBC bag sewing machines deliver unmatched efficiency and reliability for industrial packaging. By combining advanced technologies with customer-centric support, we help manufacturers achieve higher productivity and sustainability. Discover how our solutions can transform your production line today.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025