car seat cover stitching machine

The Importance of Stitching Machines in Car Seat Cover Production

In the automotive accessories industry, car seat covers are not just a necessity for protection against wear and tear; they also serve as a means of personalization for vehicle owners. Among the critical components in the production of high-quality car seat covers is the stitching machine. This machinery plays a pivotal role in ensuring durability, aesthetic appeal, and functionality of the finished product.

Understanding the Role of Stitching Machines

Stitching machines, particularly heavy-duty sewing machines, are specifically designed to handle the robust materials typically used in car seat covers such as leather, vinyl, and heavy-duty fabrics. These machines ensure that the seams of car seat covers are not only strong enough to withstand regular use but also attractive enough to enhance the overall look of the vehicle's interior.

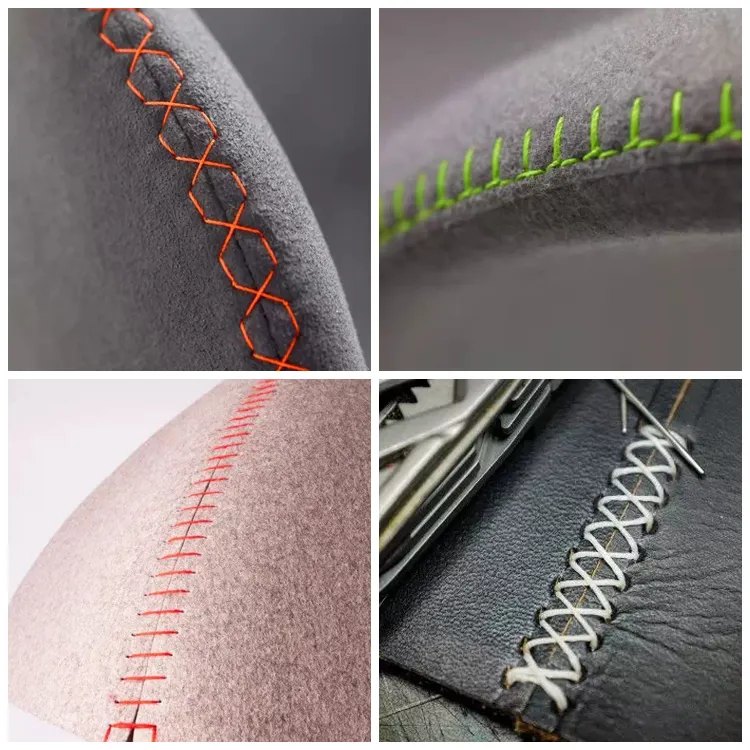

The stitching process involves various techniques, including straight stitch, zigzag stitch, and overlock stitch. Each of these methods serves a distinct purpose. For example, straight stitching is commonly used for seams that demand strength and durability, while zigzag stitching can provide flexibility and resistance to fraying. The choice of stitch type is determined by the material being used, the specific design of the seat cover, and the expected wear and tear.

Efficiency and Precision in Production

Modern stitching machines come equipped with advanced technologies that boost efficiency and precision in production. Many of these machines are programmable, allowing manufacturers to set specifications that ensure uniformity across multiple pieces. This consistency is crucial, not just for mass production but also for meeting customer expectations in terms of fit and finish.

Furthermore, computer-aided design (CAD) software is often utilized in conjunction with stitching machines. This integration allows designers to create intricate patterns and styles that can be flawlessly executed by the stitching machine. The ability to innovate while maintaining high production standards has made stitching machines indispensable in the automotive accessory industry.

car seat cover stitching machine

Addressing Quality and Durability

When it comes to car seat covers, quality and durability are paramount. A poorly stitched cover can result in fraying seams, which not only affects the visual appeal of the interior but can also pose safety risks if they interfere with seat functionality. High-quality stitching machines feature adjustable tension controls, allowing operators to fine-tune the stitch for different materials and thicknesses. This adaptability is essential for producing covers that are not only aesthetically pleasing but also long-lasting.

Additionally, the importance of thread selection cannot be overstated. Using high-strength threads that resist wear and fading ensures that even after prolonged exposure to sunlight and use, car seat covers retain their integrity and appearance. Advanced stitching machines are capable of accommodating a variety of thread types, further enhancing their functionality.

The Edge in Customization

In a world where personalization is highly sought after, the customization of car seat covers has gained immense popularity. Stitching machines facilitate this trend by allowing manufacturers to incorporate unique designs, logos, and even personalized embroidery. This capability not only attracts customers but also allows businesses to differentiate themselves in a competitive market.

For instance, luxury automotive brands often use specialized stitching techniques to create bespoke interiors that reflect the brand's identity. High-end stitching machines can replicate intricate designs with precision, ensuring that each custom order meets the exact standards expected by discerning clientele.

Conclusion

In conclusion, the importance of stitching machines in the production of car seat covers cannot be overstated. They are vital for ensuring quality, durability, and customization in a market that increasingly values both functionality and aesthetics. As technology continues to advance, we can expect further innovations in stitching machinery, paving the way for even more impressive designs and higher-quality products. For manufacturers in the automotive accessories industry, investing in state-of-the-art stitching machines is not just a business decision; it is a commitment to excellence that resonates with consumers looking for the best for their vehicles.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025