Efficient Solutions for Bag Sealing Machines in Modern Packaging Operations

The Importance of Bag Sealing Machines in Modern Packaging

In the fast-paced world of manufacturing and distribution, efficiency and quality control are paramount. One of the unsung heroes of the packaging industry is the bag sealing machine. These machines play a crucial role in ensuring that products are adequately sealed, extending their shelf life, and maintaining quality. With advancements in technology, bag sealing machines have evolved, becoming more efficient and user-friendly.

Functionality and Types of Bag Sealing Machines

Bag sealing machines are designed to seal various types of bags, including plastic, foil, and paper. These machines use heat, pressure, or adhesive to create a secure closure. There are several types of bag sealing machines, including heat sealers, impulse sealers, vacuum sealers, and band sealers. Each type serves a specific purpose and is suited for different packaging needs.

1. Heat Sealers These machines utilize heat to melt the edges of plastic bags, creating a strong seal. They are commonly used in food packaging, as they provide airtight seals that help to prevent spoilage.

2. Impulse Sealers These are ideal for low-volume operations, where the sealing is done on an as-needed basis. They provide quick and efficient sealing without the need for preheating.

3. Vacuum Sealers These are particularly beneficial for food products, as they remove air from the bag before sealing. This vacuum sealing process helps to extend the freshness of perishable items and reduces freezer burn.

4. Band Sealers Designed for high-volume production, band sealers continuously seal bags as they move along a conveyor. This type of machine is often found in large manufacturing facilities where speed is a priority.

Benefits of Using Bag Sealing Machines

The advantages of incorporating bag sealing machines into packaging processes are numerous. Firstly, they significantly enhance product shelf life. By maintaining an airtight environment, these machines minimize exposure to air, moisture, and contaminants, which are the primary factors leading to spoilage.

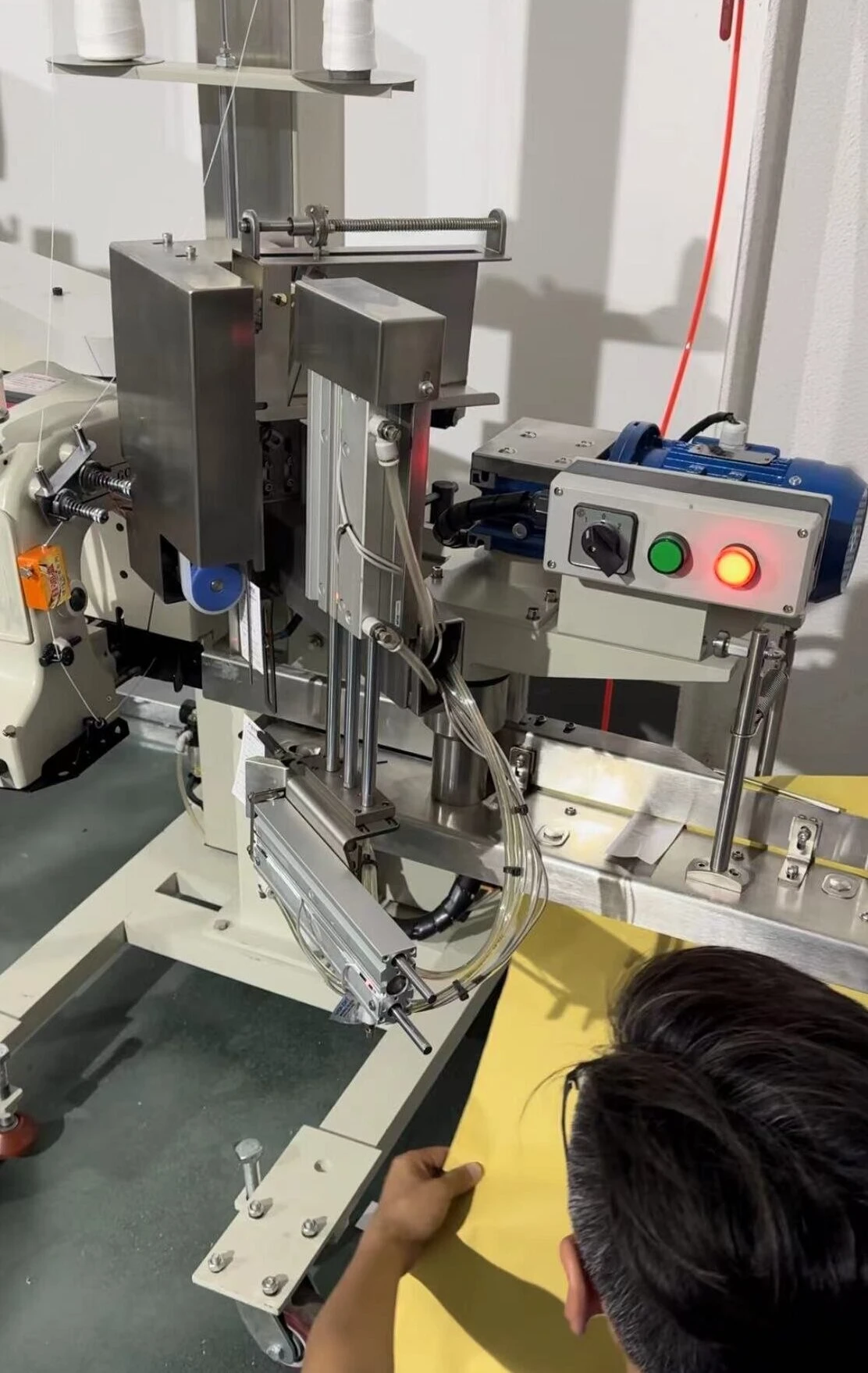

bag sealing machine

Secondly, bag sealing machines improve operational efficiency. Automating the sealing process reduces the time and labor required for manual sealing, allowing employees to focus on other essential tasks. This increase in productivity can lead to faster turnaround times and enhanced overall output.

Moreover, bag sealing machines contribute to consistency and quality control. Manual sealing methods can vary in effectiveness, leading to inconsistent seals that may compromise product safety. Machines ensure that each seal meets specific quality standards, reducing the risk of leaks and contamination.

Industry Applications

Bag sealing machines are utilized across various industries, including food and beverage, pharmaceuticals, electronics, and consumer goods. In the food industry, they are indispensable for packaging snacks, frozen foods, and ready-to-eat meals. In pharmaceuticals, sealing machines are used to ensure that medicinal products are safely packaged, preventing tampering and contamination. For electronics and consumer goods, sealing provides protection against dust and moisture, ensuring that products reach consumers in optimal condition.

Choosing the Right Bag Sealing Machine

When selecting bag sealing machines, businesses should consider factors such as production volume, bag material, seal strength requirements, and budget. It's essential to assess the specific needs of the packaging operation to choose the right machine that can optimize efficiency while providing reliable sealing.

Future Trends in Bag Sealing Technology

As technology continues to advance, the future of bag sealing machines looks promising. Innovations such as smart sealing machines equipped with sensors and automation capabilities are emerging. These enhancements can monitor sealing quality in real-time, ensuring that any defects are addressed immediately, which ultimately increases the reliability of the packaging process.

In conclusion, bag sealing machines are vital components of the packaging industry, offering numerous benefits ranging from increased shelf life and operational efficiency to improved quality control. As businesses continue to seek ways to enhance their packaging processes, the importance of investing in advanced bag sealing technology will only grow, paving the way for a more efficient and reliable future in product packaging.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025