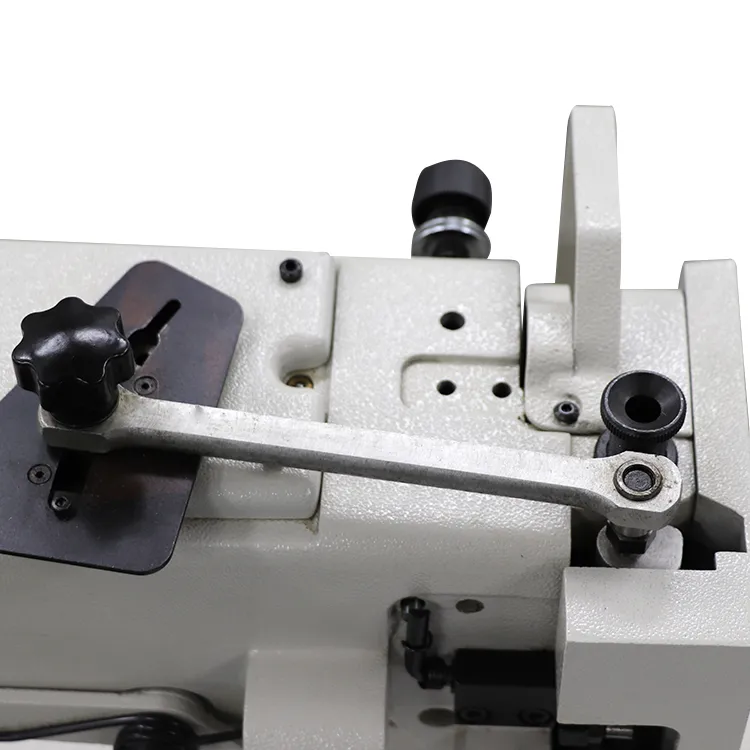

bags closer sewing machine

The Importance of the Bag Closer Sewing Machine in Modern Manufacturing

In the world of manufacturing and textiles, the bag closer sewing machine is an invaluable tool that plays a critical role in the packaging and closing of various types of bags. Whether dealing with agricultural products, food items, or industrial materials, the ability to securely seal a bag is crucial for maintaining product integrity and ensuring safe transportation. This article explores the significance of bag closer sewing machines, their functionality, and their impact on various industries.

Understanding the Bag Closer Sewing Machine

A bag closer sewing machine is specifically designed to stitch the openings of bags securely. These machines are often utilized for closing sacks made of fabric, paper, or synthetic materials. They employ different stitching techniques to ensure the bags are tamper-proof and resistant to environmental factors.

There are various types of bag closer sewing machines, including portable models and stationary versions. Portable machines are favored for their versatility and ease of use, particularly in agricultural settings where bags need to be closed on-site. Stationary machines, on the other hand, are typically employed in factories for high-volume production.

Key Features and Mechanisms

The most common type of bag closer sewing machine utilizes a chain stitch, a technique that provides durability and strength. The machines are equipped with robust feeding mechanisms that ensure even and consistent stitching, regardless of the material thickness. Additionally, modern machines often come with adjustable tension settings, allowing operators to customize the closure process based on the specific requirements of the bag material.

Another notable feature is the speed of operation. Advanced bag closer machines can stitch bags at speeds of up to 2000 stitches per minute, significantly enhancing production efficiency. Moreover, the ability to integrate with automated systems helps streamline the process, reducing manual labor and human errors.

Applications Across Industries

bags closer sewing machine

Bag closer sewing machines find applications in a multitude of sectors. In agriculture, they are essential for closing bags of grains, seeds, and fertilizers. The agricultural industry benefits from these machines not only in sealing but also in ensuring that products remain uncontaminated during storage and transport.

In the food industry, these machines are pivotal for sealing bags of flour, sugar, and pet food. The prevention of spoilage and contamination is vital in food production, making the ability to tightly close packaging essential for food safety protocols.

Furthermore, industrial applications often require the packaging of chemicals, minerals, and raw materials

. The bag closer sewing machine ensures that these products are contained securely within their packaging to prevent spillage, which could lead to contamination or environmental hazards.Benefits of Using Bag Closer Sewing Machines

Utilizing a bag closer sewing machine brings several advantages. Firstly, it enhances productivity. By automating the bag closure process, companies can significantly reduce the time spent on packaging, allowing for quicker turnaround times and the ability to meet higher demand.

Secondly, it improves product quality. A consistent and secure closure reduces the risk of leaks and contamination, thereby enhancing customer satisfaction and maintaining brand integrity.

Finally, these machines contribute to cost efficiency. By reducing manual labor and improving the reliability of the closure process, companies can lower operational costs and increase profitability.

Conclusion

In summary, the bag closer sewing machine serves as a cornerstone of various manufacturing processes across many industries. Its ability to efficiently and securely close bags is vital for product preservation and safety, making it a crucial investment for any business engaged in packaging. As technology advances, we can expect to see even more innovations in the design and efficiency of bag closer sewing machines, further solidifying their role in modern manufacturing. Whether in agriculture, food production, or industrial applications, this machine is undoubtedly a key player in maintaining the quality and integrity of products during their journey from production to consumer.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025