Auto Lubrication System for Efficient Sewing Machines

The Evolution of Auto Oil Sewing Machines

In the world of textile and garment manufacturing, the importance of efficiency and precision cannot be overstated. This is where the auto oil sewing machine comes into play. These machines have revolutionized the sewing industry by integrating automatic lubricating systems that enhance performance while reducing maintenance downtime.

The concept of auto oil sewing machines emerged from the need for continuous operation in high-volume production environments. Traditional sewing machines required manual lubrication, which could interrupt workflow and lead to inconsistencies in stitching quality. With the invention of automatic oiling systems, manufacturers could ensure that the sewing machines remained well-lubricated without the need for constant human intervention.

An auto oil sewing machine is designed with a built-in lubrication system that automatically distributes oil to critical parts of the machine. This not only minimizes wear and tear but also reduces the heat generated during the sewing process. By maintaining optimal operating conditions, these machines can sew fabrics at a faster pace without compromising on quality. For instance, the sewing speed can reach up to 5,000 stitches per minute, making them ideal for mass production.

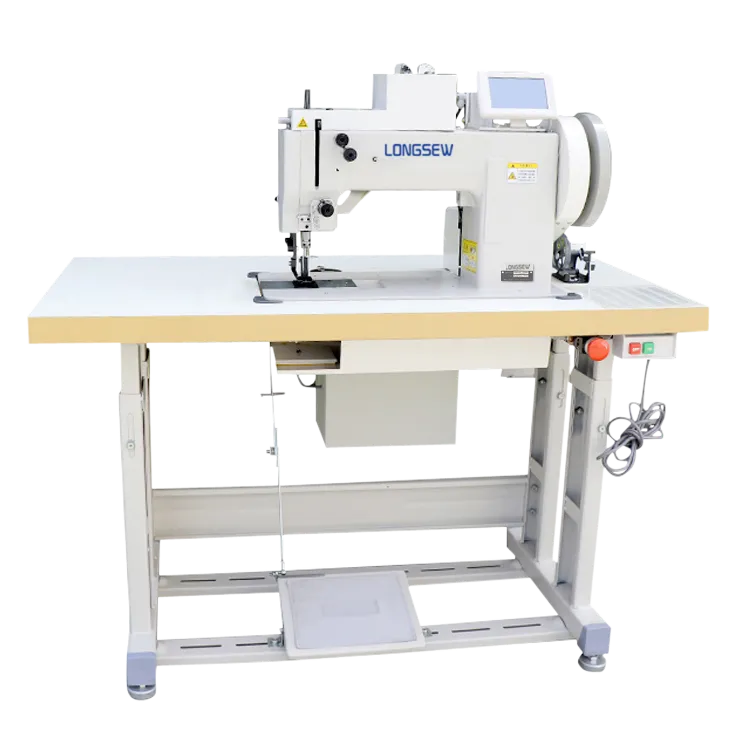

auto oil sewing machine

Moreover, the use of auto oil sewing machines significantly enhances the life span of the equipment. With consistent lubrication, the machines experience less friction, which translates to fewer breakdowns and repairs. This reliability is crucial for businesses that depend on their machinery to meet tight deadlines and production quotas.

In addition to durability, auto oil sewing machines also contribute to improved workplace safety. Manual lubrication often involves handling oils and greases, which can pose risks if not done correctly. By automating this process, manufacturers can create a safer working environment for their employees, thereby increasing productivity.

Today, auto oil sewing machines come equipped with various advanced features, such as digital controls and sensors that monitor the lubrication levels. These innovations further streamline the sewing process and help operators manage their machines more effectively.

In conclusion, the development of auto oil sewing machines has transformed the textile industry by enhancing efficiency, reducing downtime, and improving safety. As technology continues to advance, we can expect these machines to evolve even further, paving the way for a more productive and sustainable future in garment manufacturing. As businesses seek to maximize productivity while maintaining high quality, the role of auto oil sewing machines will undoubtedly remain crucial in the industry.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025