Affordable Prices for Automatic Stitching Machines in Today's Market

The Price of Automatic Stitching Machines An Overview

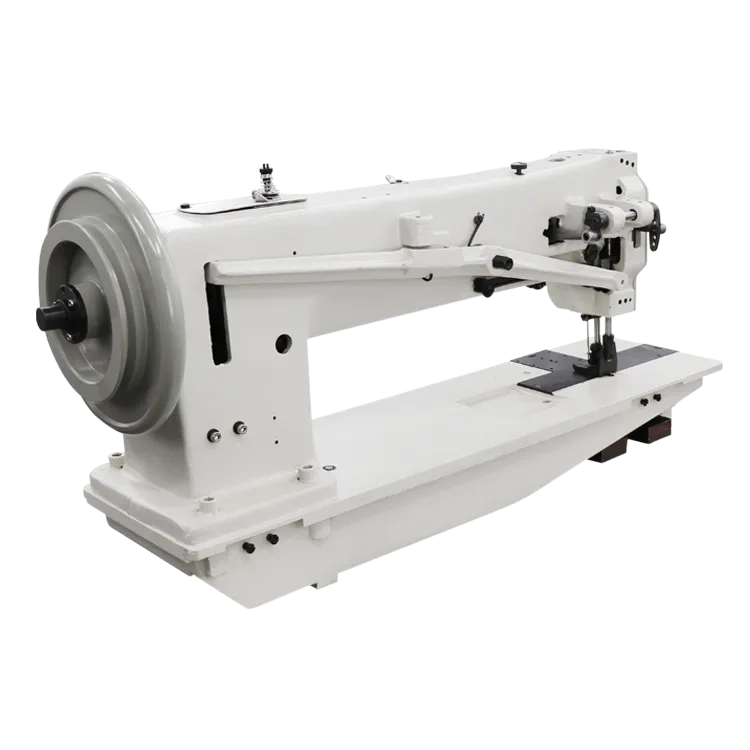

In the ever-evolving landscape of textile manufacturing, automatic stitching machines have emerged as indispensable tools for enhancing productivity and ensuring consistency in garment production

. As the demand for high-quality textiles continues to rise, so does the interest in understanding the price points of these advanced machines.The cost of automatic stitching machines can vary significantly based on several factors including the machine's functionality, brand reputation, and technology. Basic models that serve simple stitching purposes can start at a relatively low price, often ranging from $1,000 to $5,000. These machines typically cater to small businesses or home users who require straightforward, reliable stitching without the bells and whistles.

On the other end of the spectrum, high-end automatic stitching machines equipped with advanced features such as automatic thread trimming, programmable sewing patterns, and integrated quality control systems can soar in price, reaching upwards of $50,000 or more. These sophisticated machines are designed for large-scale production facilities where efficiency and speed are paramount. They not only reduce labor costs but also minimize the risk of human error, resulting in a higher output of consistently high-quality products.

automatic stitching machine price

When considering the price, it’s essential to also take into account the long-term benefits of investing in a more expensive machine. For instance, while the initial outlay may be high, the return on investment can be substantial when factoring in increased production rates, reduced labor costs, and lower material waste. Businesses must assess their production needs, the complexity of the garments they produce, and their budget constraints when making such a critical decision.

Additionally, the market is rife with competition, and prices can fluctuate based on geographical location, supplier relationships, and rapid technological advancements. Buyers are encouraged to conduct thorough research, seek reviews, and possibly negotiate prices with manufacturers. Furthermore, considering the total cost of ownership—including maintenance, parts replacement, and any necessary training—can lead to a more informed purchasing decision.

In conclusion, while the price of automatic stitching machines can vary widely, understanding the cost factors and evaluating specific business needs will lead to a more strategic and fruitful investment. By equipping themselves with the right machinery, textile manufacturers can not only improve efficiency but also enhance their market competitiveness in a demanding industry.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025